Engine-mounting bracket

A technology of engine mounts and mount cushions, which is applied to power plants, jet propulsion devices, internal combustion propulsion devices, etc., can solve the problems of increased number of engine parts, poor engine NVH performance, high management and manufacturing costs, and achieve structural Effects of compactness, reduction in the number of mounting bolts, and reduction in management and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further illustrate structure of the present invention below in conjunction with accompanying drawing:

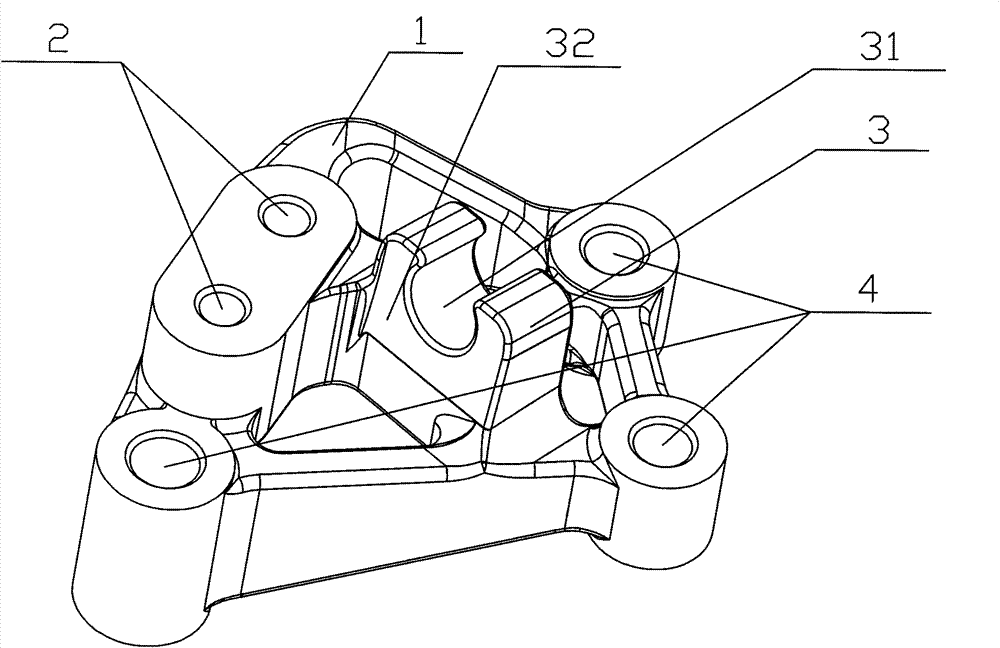

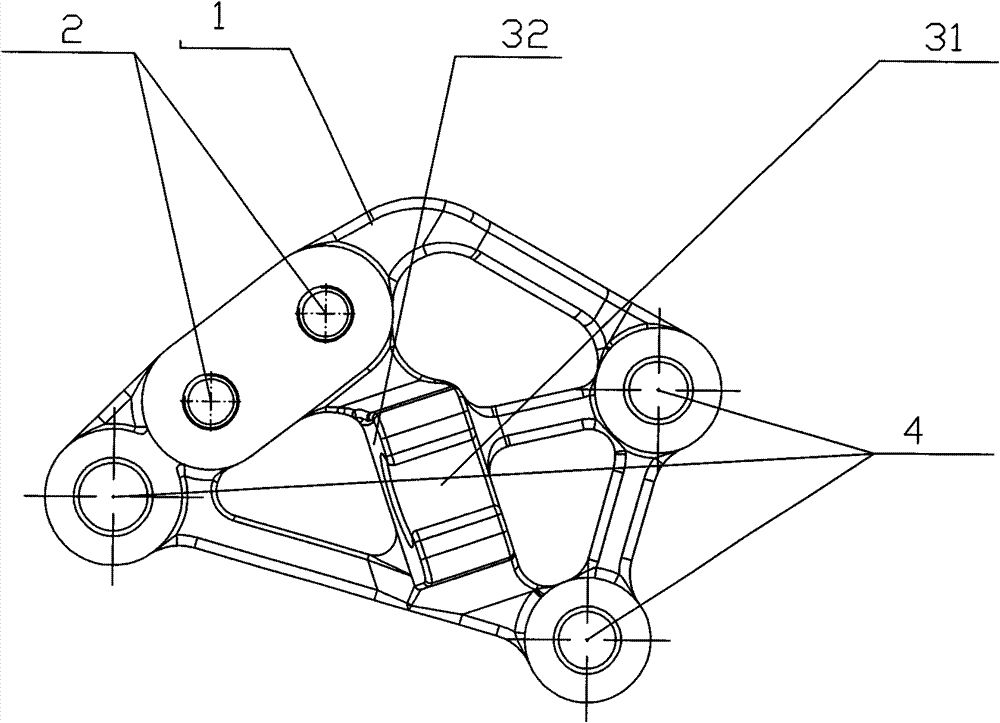

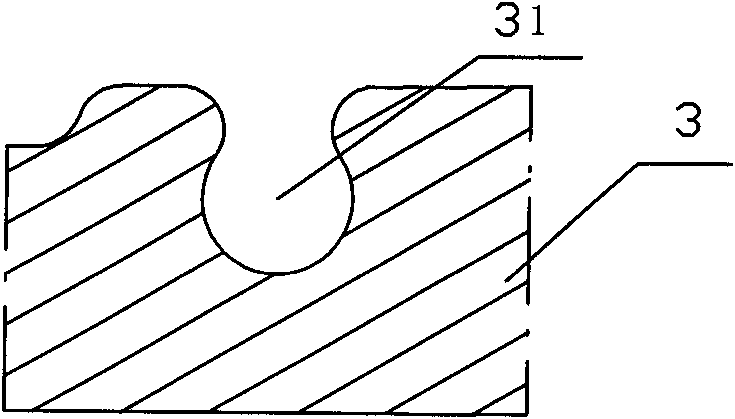

[0015] Such as Figure 1 to Figure 2 As shown, the main body of the engine mount bracket is an integrally formed quadrilateral bracket body 1, and three corners of the bracket body 1 are respectively arranged with transmission mounting holes 4. One side of the bracket body 1 is integrally formed with a suspending cushion mounting boss 2, and the boss has mounting holes. There is a reinforcing beam in the middle of the bracket body 1, on which a clutch cable guide 3 is integrally formed. see image 3 , the clutch cable guide 3 is a boss structure with a horizontal slot, the slot is the guide track 31 of the clutch cable, and the side wall of the boss is the guide limit plane 32 of the flange surface of the clutch cable head.

[0016] see Figure 4 , the engine suspension bracket assembly 6 connects the powertrain and the vehicle body through the suspension cushion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com