Airplane threading pipe device

A technology for threading pipes and aircraft, which is applied in the field of aircraft threading pipe devices, can solve problems such as the inability to form structural isolation distances, and achieve the effect of reducing the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

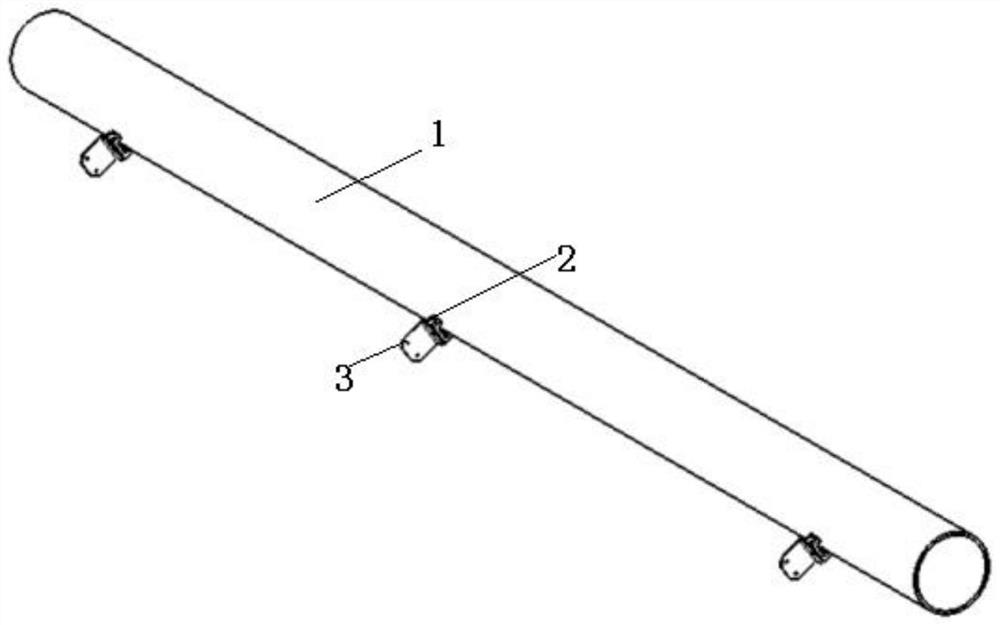

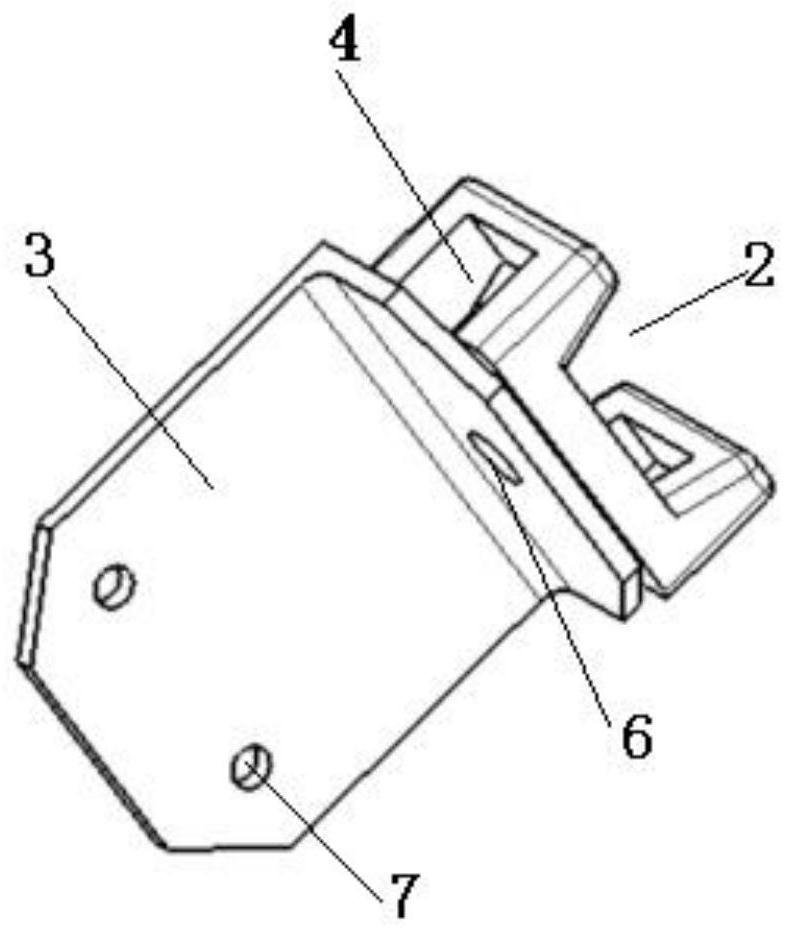

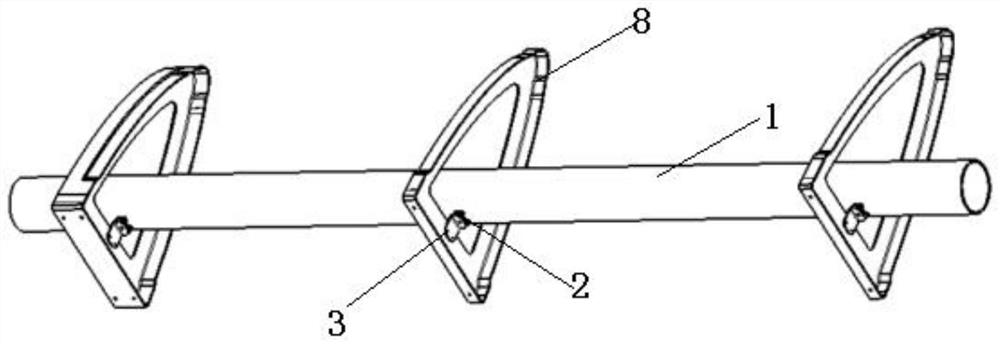

[0016] like figure 1 and figure 2 An aircraft threading pipe device shown includes a threading pipe body 1, a threading pipe support 2 is installed at the bottom of the threading pipe body 1, and the threading pipe support 2 is connected to a bracket 3; wherein the threading pipe support 2 is in the shape of a saddle, and the threading pipe There are threading pipe fixing holes 4 on both sides of the support, and the threading pipe body 1 can be tied and fixed by using binding ropes, binding tapes, etc. The bottom of the threading pipe support 2 is provided with connecting holes; The upper surface of the bracket 3 is provided with a connecting hole I6, the bracket 3 passes through the connecting hole I6 and the connecting hole through the threading pipe support 2 and the bracket 3 with countersunk bolts, and is fixed with nut locking, and there are rivets on the side of the bracket 3 hole 7.

Embodiment 2

[0018] like figure 1 and figure 2 The shown aircraft threading pipe device includes a threading pipe body 1, the threading pipe body 1 is a cylindrical pipe structure, and three threading pipe supports 2 are evenly installed at the bottom of the threading pipe body 1, and the three threading pipe supports 2 are equidistant. Distribution, the threading pipe support 2 is connected to the bracket 3; wherein the threading pipe support 2 is in the shape of a saddle, and there are threading pipe fixing holes 4 on both sides of the threading pipe support. The bottom of the threading pipe support 2 has a connecting hole; the support 3 is an L-shaped structure, and the upper surface of the support 3 has a connecting hole I6, and the support 3 passes through the connecting hole I6 and the connecting hole with a countersunk head bolt. The pipe support 2 and the bracket 3 are locked and fixed with nuts, and a rivet hole 7 is opened on the side of the bracket 3 .

[0019] The working pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com