Steel dam space truss structure unit body and arch-style steel dam

A technology of space truss and structural unit, applied in the direction of arch structure, dome roof structure, dam, etc., can solve the problems of large investment, difficult construction, large amount of materials, etc., and achieve the effect of saving project investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

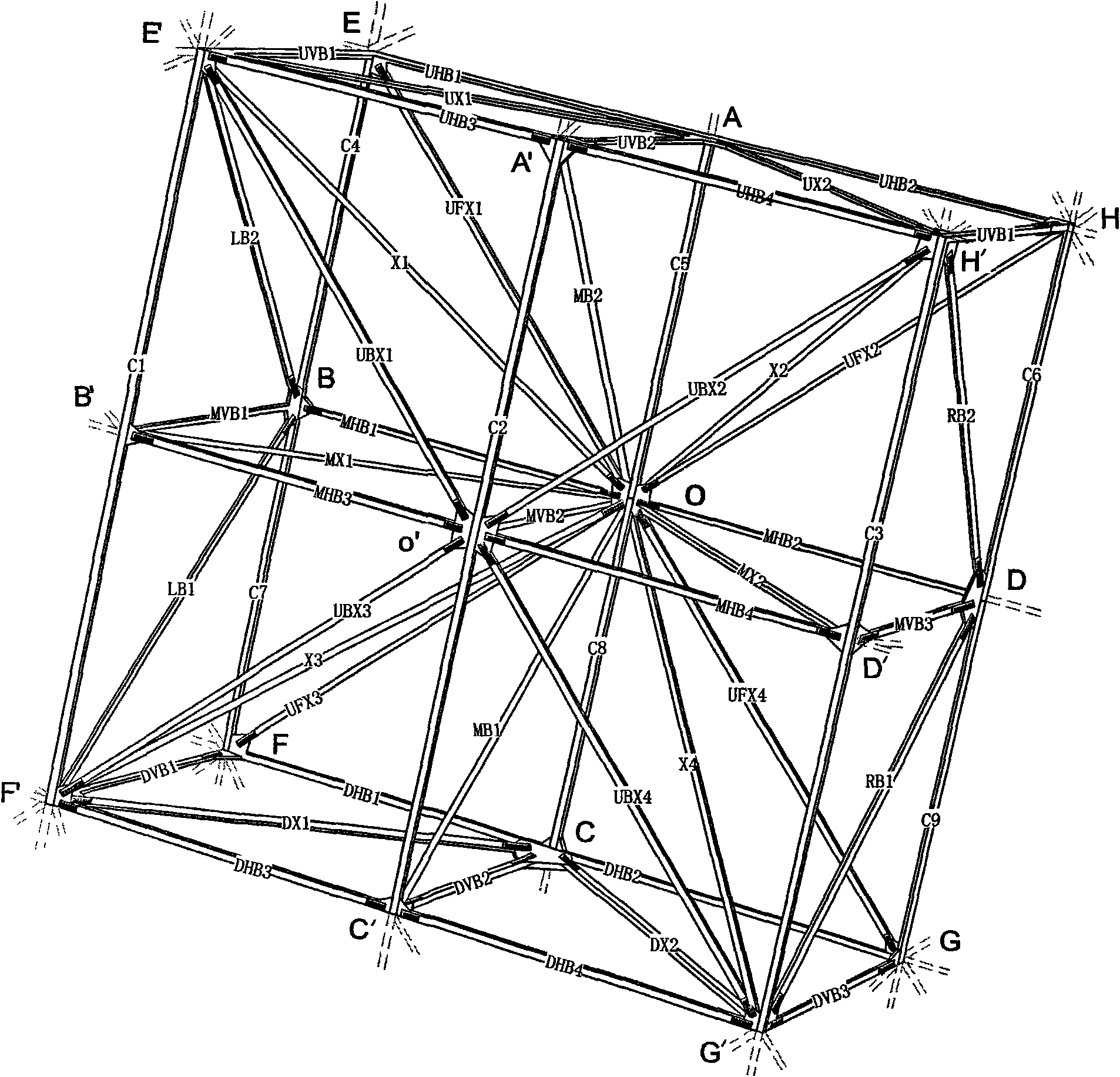

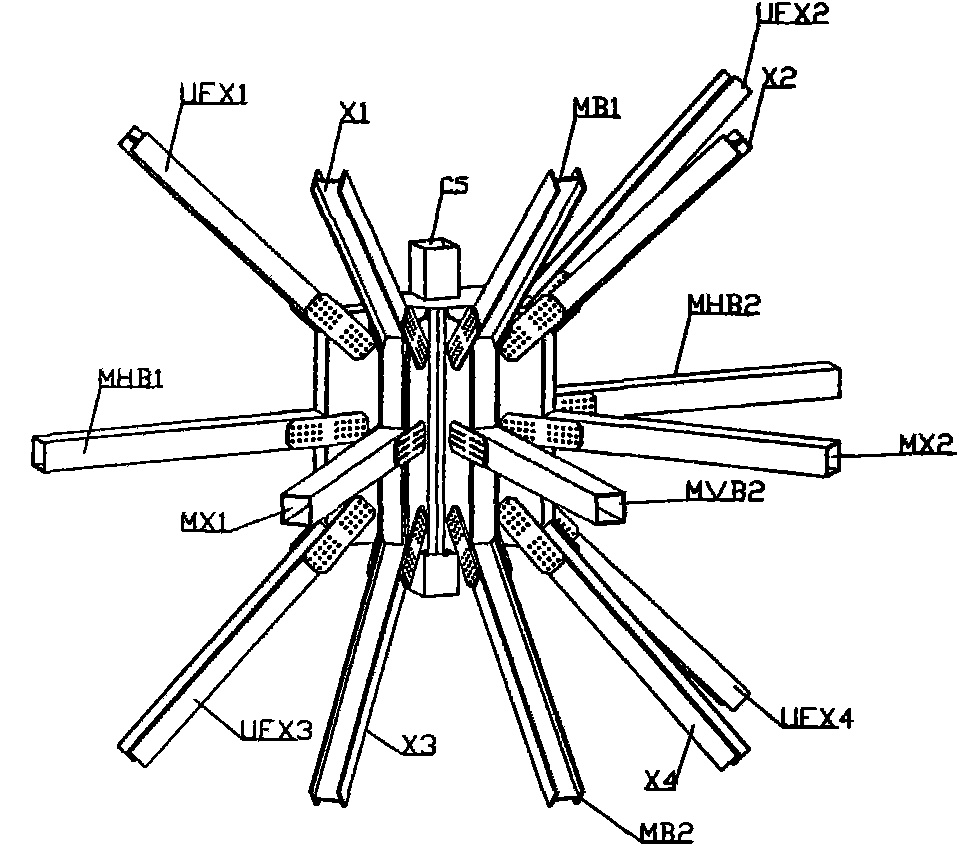

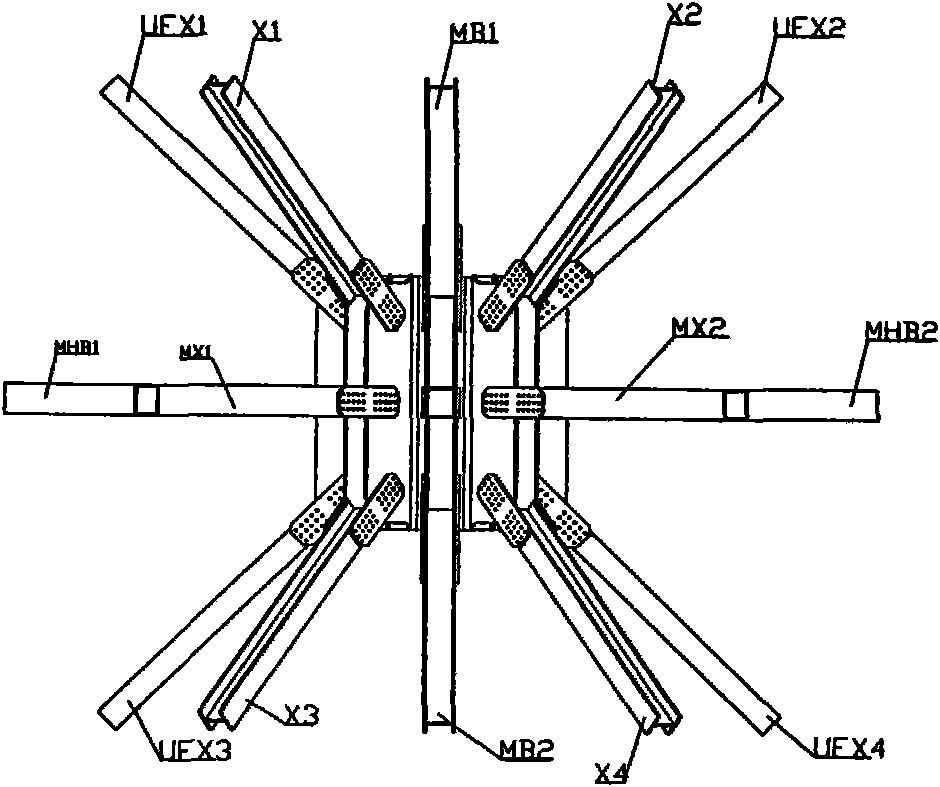

[0058] Embodiment one: see figure 1 , figure 2 , Figure 2-1-Figure 2-3 , image 3 , Figure 3-1-Figure 3-3 , Figure 4 , Figure 4-1-Figure 4-3 , Figure 5 , Figure 5-1-Figure 5-3 , a steel dam space truss structure unit body, comprising a space truss structure approximately trapezoidal hexahedron. The front and rear end surfaces of the approximately trapezoidal hexahedron space truss structure are respectively "Tian"-shaped connection structures. figure 1 The middle and front faces are the planes where nodes A, B, C, D, E, F, G, H, and O are located, and the rear faces are A', B', C', D', E', F', G', H', O'; the left, right, upper and lower sides of the frame are "day"-shaped structures, in figure 1 The middle left view is the plane where nodes E, B, F, F', B', E' are located, the right side is the plane where nodes H, D, G, G', D', H' are located, and the upper side is E , A, H, H', A', E' are the planes where the nodes are located, and the lower side is the pla...

Embodiment 2

[0069] Embodiment two: see Figure 6 , the meaning of the numbering and numbering is the same as that of the first embodiment, and the content is basically the same as that of the first embodiment, and the similarities will not be repeated. The difference is that the support plate 11 can also be fixed between the two parallel connecting ears 9 . The supporting plate 11 is vertically fixed with the two connecting ears 9 respectively, and one end of the connecting ear 9 and the supporting plate 11 therebetween is fixed on the side of the connecting rod 8 (vertical column connecting rod) (that is, one end of the connecting ear 9 is connected to the connecting rod). Rod 8 is contacted and fixed, and one end of support plate 11 is contacted or fixed by connecting rod 8), the other end of connecting ear 9 and the support plate 11 therebetween is abutted (or butt fixed) with the end face of horizontal or oblique connecting rod 8, and A connecting piece 10 is fixed on the adjacent sid...

Embodiment 3

[0070] Embodiment 3: the accompanying drawings are not drawn, the meaning is basically the same as that of the embodiment, and the similarities will not be repeated. The difference is: the connecting rods are circular shaped steel connecting rods, and the two ends of the circular connecting rods are used as parallel planes. For example, the two ends of the circular connecting rod are made into a square steel shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com