Combined multi-arch type steel-structure dam

A technology for steel structure dams and multiple arches, applied in arch dams, dams, water conservancy projects, etc., can solve the problems of large investment, long construction period, and poor adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

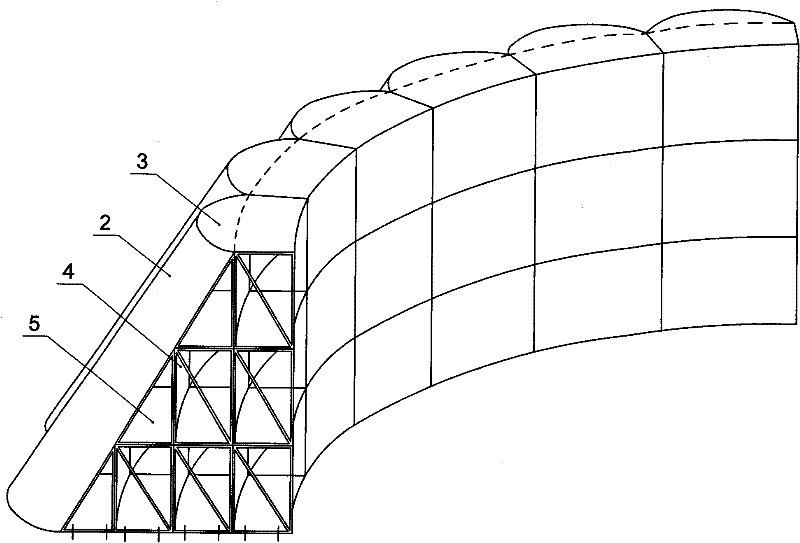

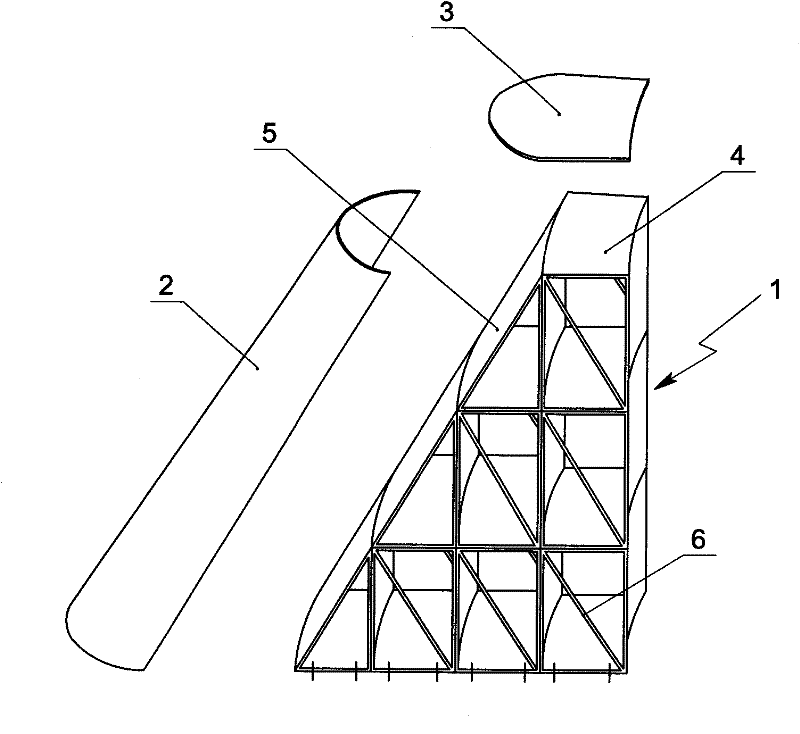

[0052] Embodiment one: see figure 1 , Picture 1-1 , Figure 1-2 , Figure 3-Figure 10 , a composite multi-arch steel dam, comprising a dam bottom reinforced concrete cap 11 and pre-embedded fixings, side piers 12 made of reinforced concrete structures on both sides of the dam and pre-embedded fixings. The shapes of the reinforced concrete cap 11 at the bottom of the dam and the reinforced concrete side piers 12 on both banks mainly depend on the shape of the main body of the steel structure dam. From image 3 It can be seen that the width of the reinforced concrete cap 11 at the bottom of the dam and the reinforced concrete side piers 12 on both banks are appropriately greater than the width of the bottom or side of the main body of the steel structure dam.

[0053] When constructing a steel dam, firstly, standardize the design of the dam bottom cap and side piers according to the overall actual shape of the steel dam main design, the width of the dam bottom, the height o...

Embodiment 2

[0068] Embodiment 2: The accompanying drawings are not drawn, and the content is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is: in this embodiment, the small arched unit body A of the box-shaped rectangular section and the small box-shaped triangular section The fixed relationship between the adjacent sides of the arched unit body B is fixed by bolts. For example, matching fixing holes are respectively provided on the adjacent double-layer public side walls, and high-strength bolts, nuts, and pads are used in the corresponding fixing holes. The film is fixed, not detailed.

Embodiment 3

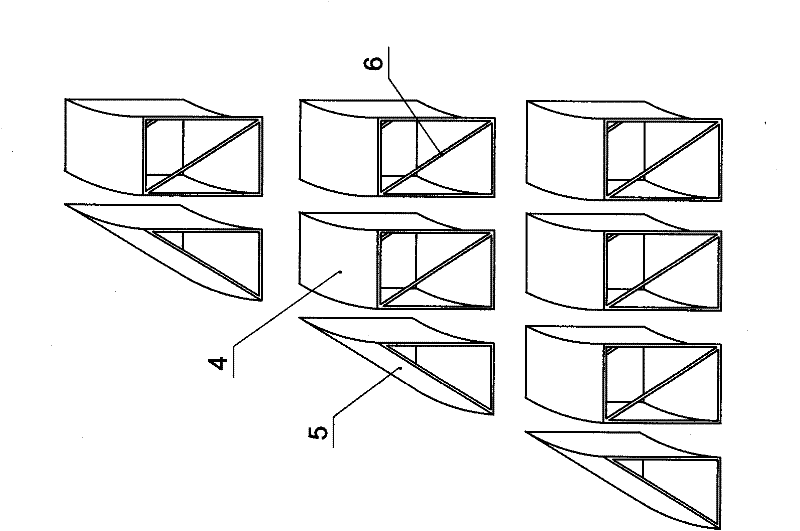

[0069] Embodiment three: see Figure 11 , Figure 11-1 , Figure 11-2 , Figure 11-2-1 , another combined arch steel dam, the main content is the same as that of Embodiment 1, and the similarities will not be repeated. The difference is: each box-type rectangular cross-section small arch unit A The side adjacent to the box-type triangular section small arched unit body B is a common adjacent side of a single layer.

[0070] In this embodiment, each box-shaped rectangular cross-section small arch unit body A and box-shaped triangular cross-section small arch unit body B constituting the box-shaped arch support body are respectively fixed on site by welding or fixed by other means. see respectively Figure 11 , Figure 11-1 , Figure 11-2 , Figure 11-2-1 The small arched unit body A of the box-type rectangular cross-section is formed by welding and fixing the arc-shaped side plates 8, the plane end plates 9 with arc-shaped edges, and the oblique connecting rods 6 on site...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com