Assembly type rigid supporting protection foundation structure for buried pipelines

A rigid support, buried pipeline technology, applied in pipeline protection, pipeline support, infrastructure engineering and other directions, can solve the problems of poor pipeline stress environment, high engineering cost, poor protection effect, etc., to achieve guaranteed treatment effect, Cost saving, environmental protection, enhanced safety and durability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

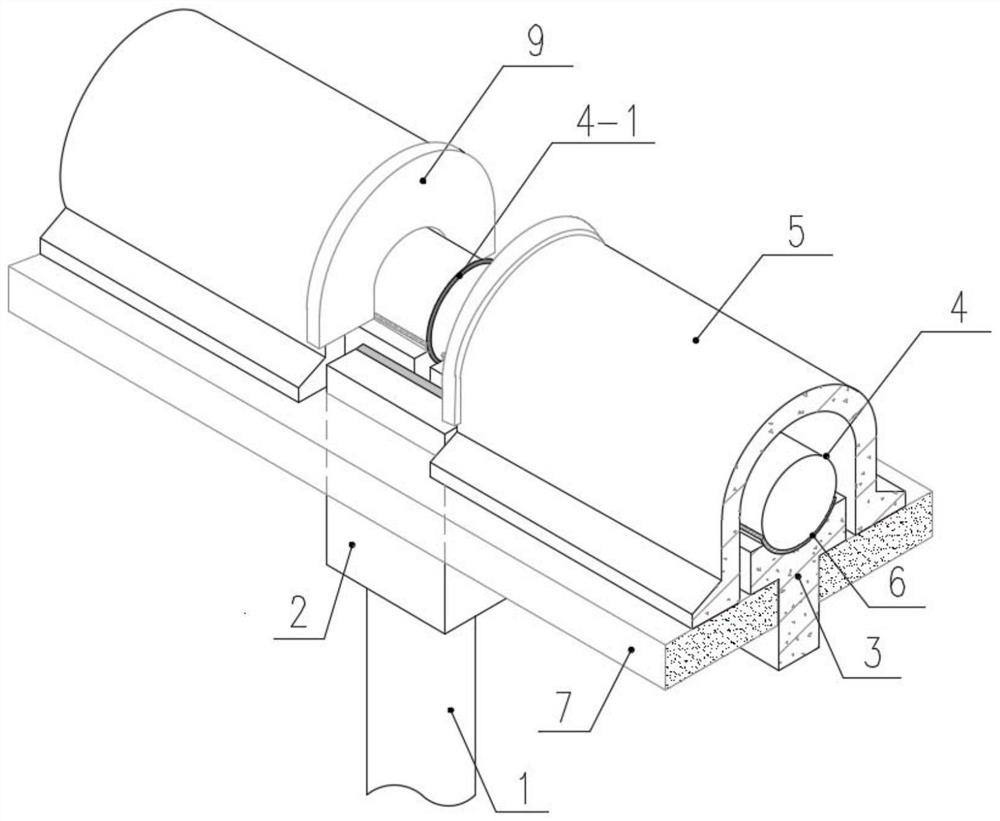

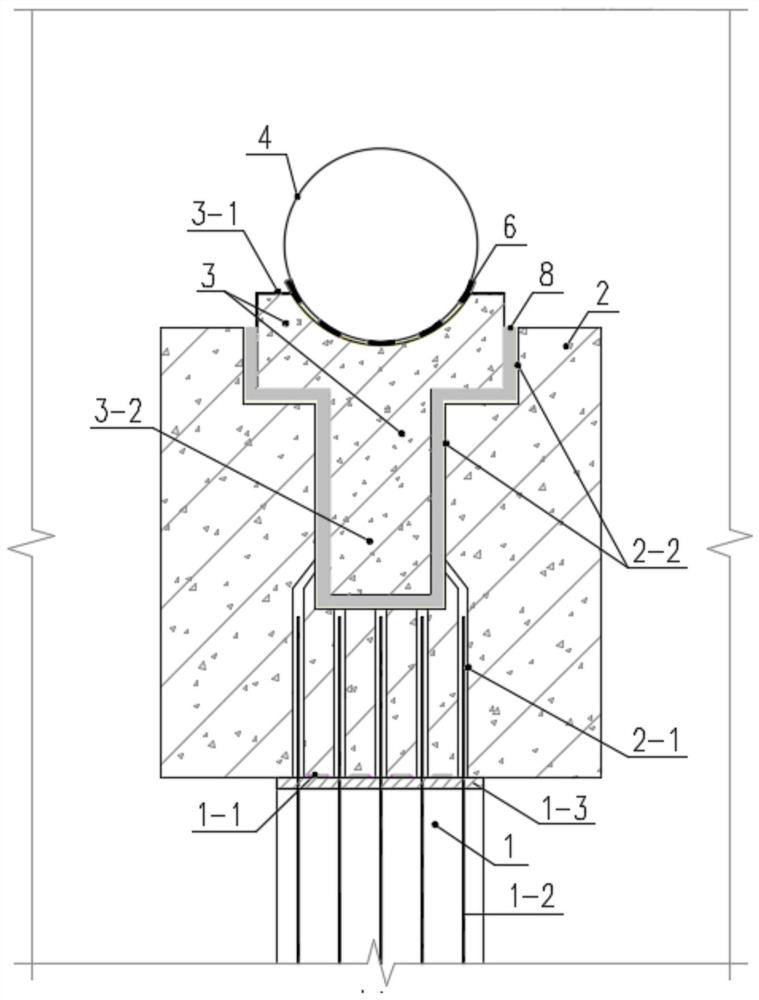

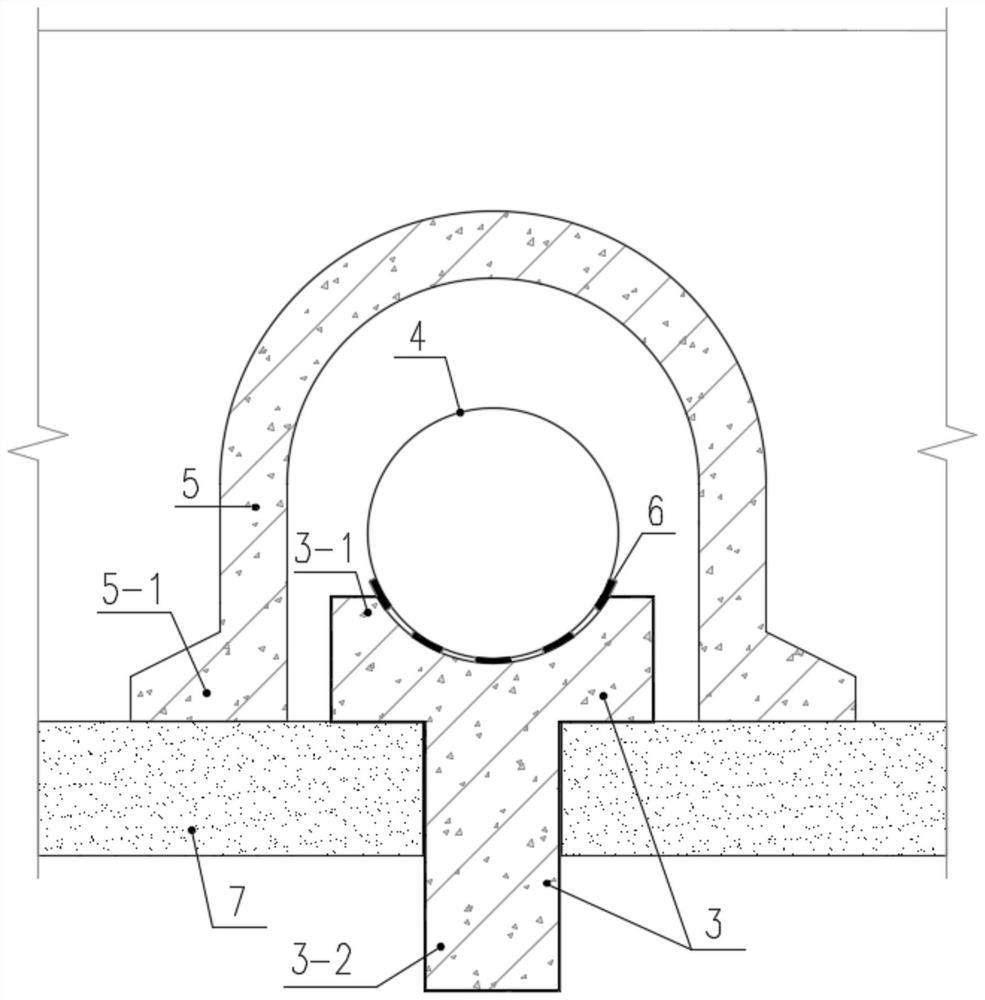

[0031] see Figure 1-3 , an assembled rigid support and protection foundation structure for buried pipeline 4, including a foundation and a number of support and protection units, the upper layer of the foundation is a sand cushion 7. The support and protection unit includes a prefabricated pile 1 and a pipe 4 carried by the prefabricated pile 1. The ports of the pipe 4 of the two support and protection units are butted, and the support and protection unit also includes at least one of a prefabricated arch ring 5 and a prefabricated foundation beam 3:

[0032] The prefabricated arch ring 5 is supported by the foundation and covers the pipe 4 , a gap is formed between the inner wall of the prefabricated arch ring 5 and the outer wall of the pipe 4 ;

[0033] In this embodiment, the support and protection unit includes a prefabricated pile 1 , a prefabricated cap 2 , a prefabricated foundation beam 3 , a prefabricated arch ring 5 and a pipe 4 . A prefabricated pile 1 is provide...

Embodiment 2

[0056] An assembled rigid support protection foundation structure for buried pipelines comprises a foundation and several support protection units, and the upper layer of the foundation is a sand cushion. The support and protection unit includes prefabricated piles and pipes carried by the prefabricated piles, the pipe ports of the two support and protection units are connected, and the support and protection unit also includes at least one of the prefabricated arch ring and the prefabricated foundation beam:

[0057] The prefabricated arch ring is supported by the foundation and covers the pipe, and a gap is formed between the inner wall of the prefabricated arch ring and the outer wall of the pipe;

[0058] Prefabricated foundation beams are supported by prefabricated piles to support the studs.

[0059] In this embodiment, the support unit includes prefabricated piles, prefabricated foundation beams, prefabricated arch rings and pipes. on the foundation.

Embodiment 3

[0061] An assembled rigid support protection foundation structure for buried pipelines comprises a foundation and several support protection units, and the upper layer of the foundation is a sand cushion.

[0062] In this embodiment, the support and protection unit includes prefabricated piles, prefabricated arch rings and pipes. The two ends of the pipes are directly supported on the prefabricated piles. foundation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com