Shaft lifting device for leaf springs suspension

A leaf spring and axle technology is applied in the field of axle lifting devices suspended by leaf springs. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

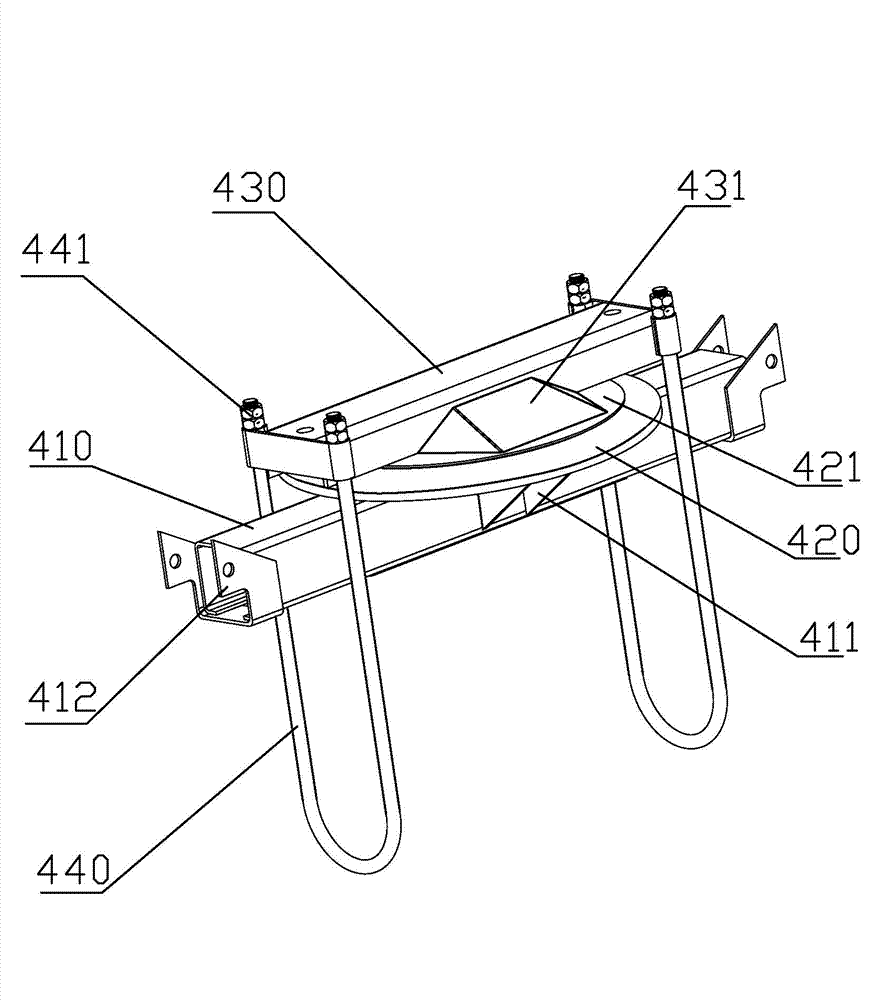

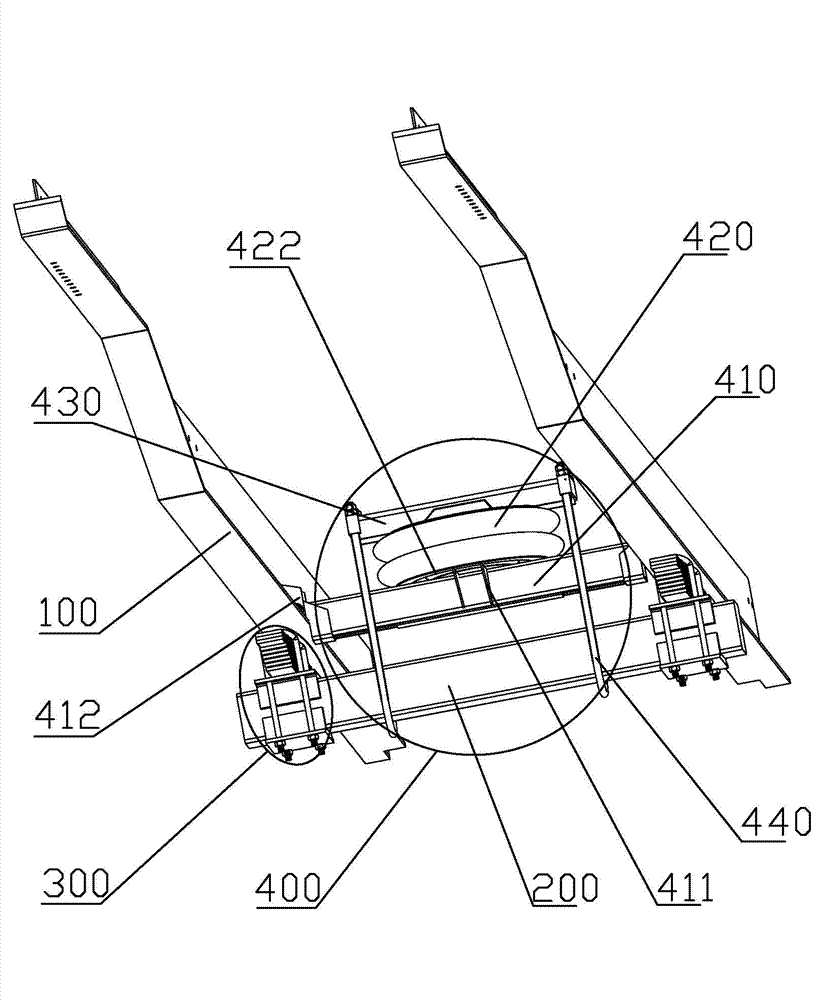

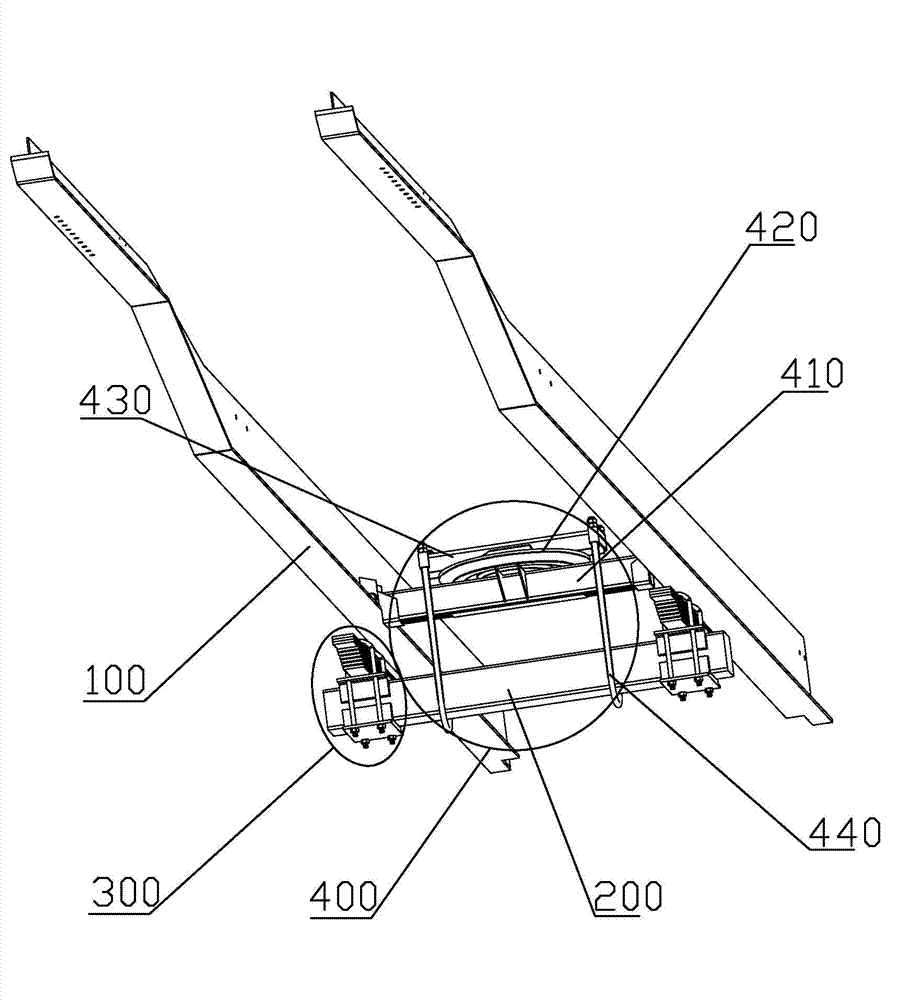

[0035] A kind of leaf spring suspension axle lifting device of the present invention, as Figure 1 to Figure 3 As shown, it includes a vehicle frame 100, an axle 200 and steel plate suspension mechanisms 300 respectively affixed to both ends of the axle 200. An axle lifting mechanism 400 is fixedly connected above the axle 200 and in the middle of the vehicle frame 100. The axle lifting mechanism 400 includes two The ends are respectively fixed to the fixed beam 410 of the vehicle frame 100, the airbag 420 which can be inflated and deflated and the movable beam 430 which are arranged on the fixed beam 410, the airbag 420 is arranged between the fixed beam 410 and the movable beam 430, and the movable beam Both ends of the 430 are fixedly connected to the lifting member 440, and the axle 200 is arranged on the lifting member 440.

[0036] The device relies on the inflation and deflation of the air bag 420 of the axle lifting mechanism 400 to lift and lower the axle 200. The dev...

Embodiment 2

[0046] The main technical solutions of this embodiment are the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

[0047] like Figure 4 , Figure 5 As shown, longitudinal guide rails 450 are respectively provided above the two ends of the fixed beam 410 , and the two ends of the movable beam 430 are slidingly matched with the guide rails 450 respectively. When the airbag 420 is inflated or deflated, the movable beam 430 moves up and down with the airbag 420. At this time, the two ends of the movable beam 430 move up or down along the guide rail 450. The setting of this structure makes the integrity of the axle lifting mechanism 400 better. When the movable beam 430 moves up and down, it will not deviate from its position, causing the lifting member 440 to receive unnecessary torsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com