Shaft-well drill rod lifter

A lifter and drilling rig technology, applied in drill pipes, drill pipes, drilling equipment, etc., can solve the problems of high labor intensity and slow speed, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

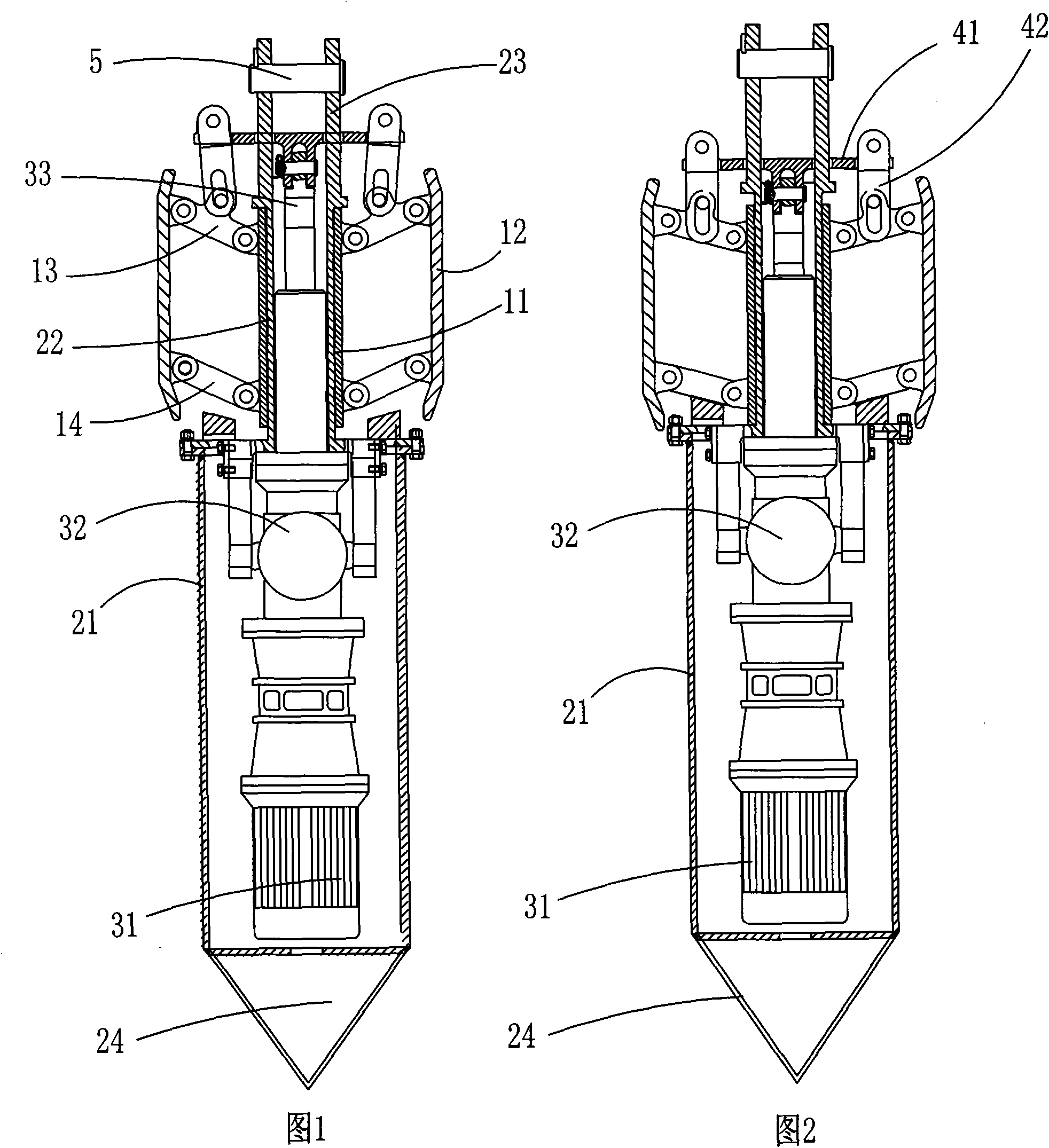

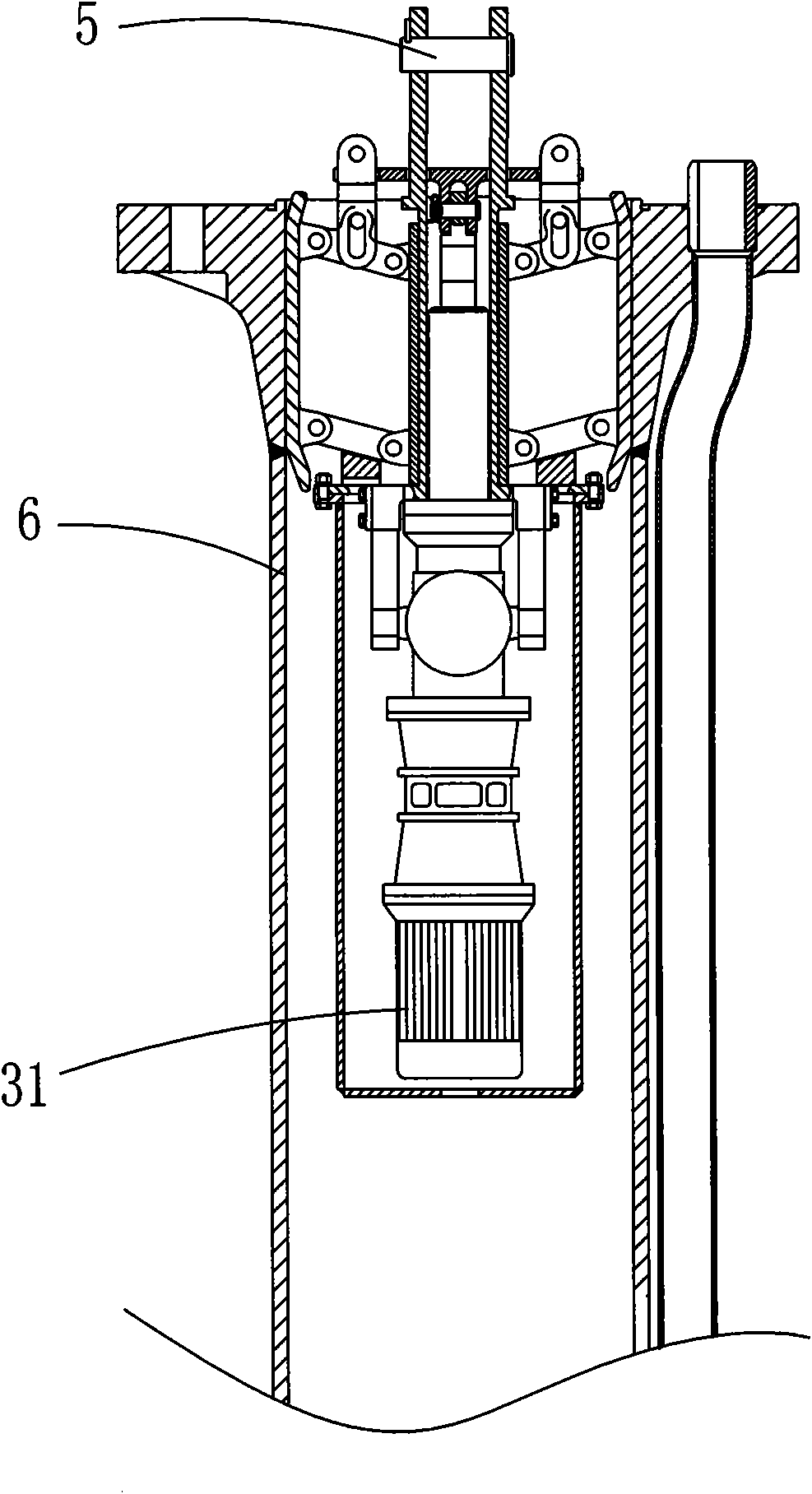

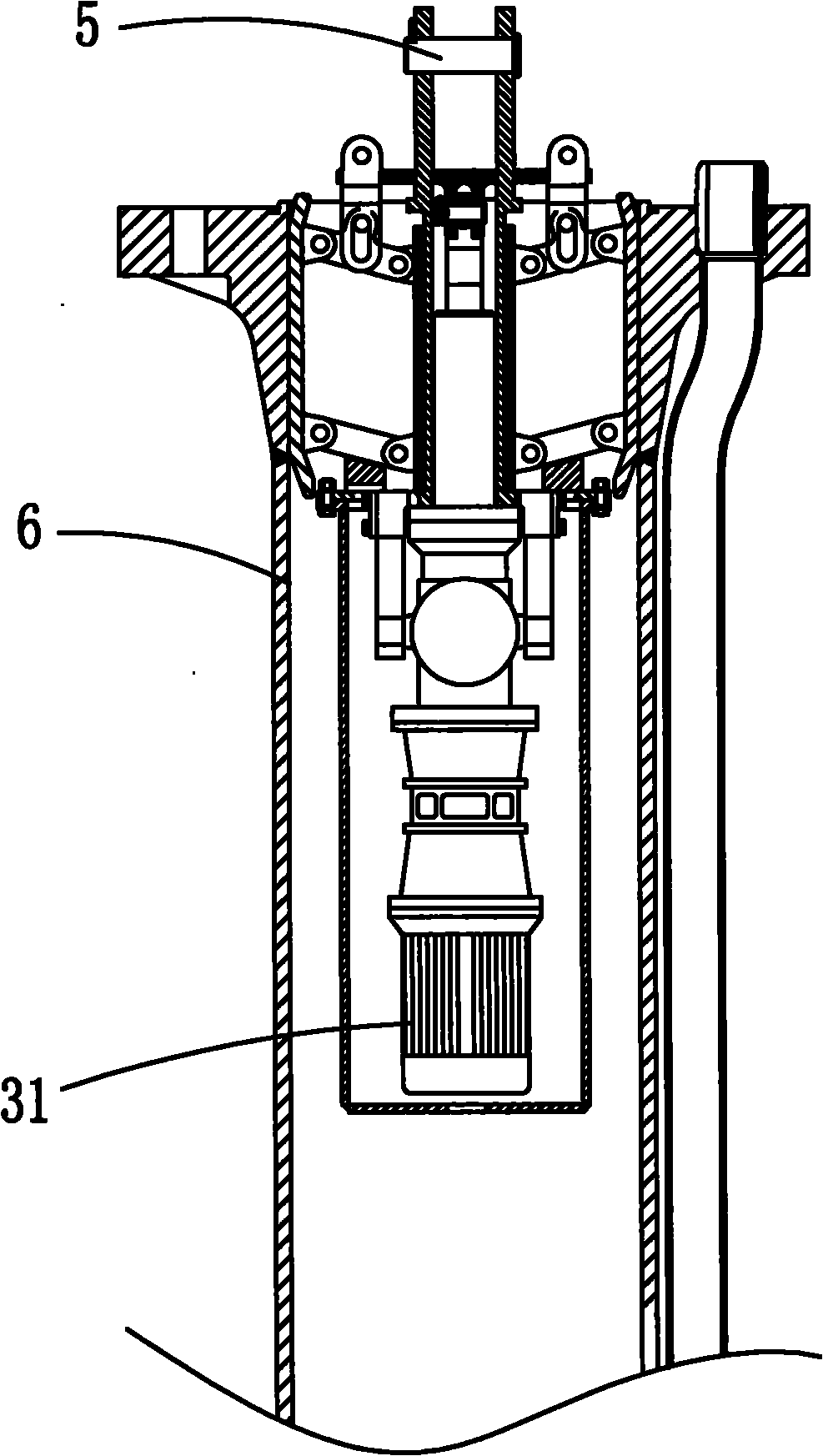

[0018] see figure 1 , figure 2 and image 3 , the structure of this embodiment is set to:

[0019] With the piston ejector rod 33 as the center, three sets of four-bar linkages are evenly distributed on the outer circumference;

[0020] The central rod 11 of the four-bar linkage mechanism is fixedly connected with the frame, and the outer rod is set as a brace 12, and the brace 12 and the central rod 11 are hinged with an upper link 13 and a lower link 14 parallel to each other;

[0021] The frame is a cylinder, in the frame cylinder, a motor 31 and an electric push rod 32 driven by the motor 31 are fixedly installed in the lower cylinder 21 below the four-bar linkage mechanism; The outside of the cylinder body 22 is the center rod 11 which is arranged around it, and the inside of the cylinder body is the piston push rod 33 which can slide axially in the middle section cylinder body 22; The hook shaft 5 for lifting is fixedly arranged on the top of the lifting rod 23;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com