Method and system for thermally washing pipeline

A technology for flushing systems and pipes, applied in flushing, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of poor water quality, long flushing time, large flushing resistance, etc., to achieve low water and power consumption, flushing Short time, good flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

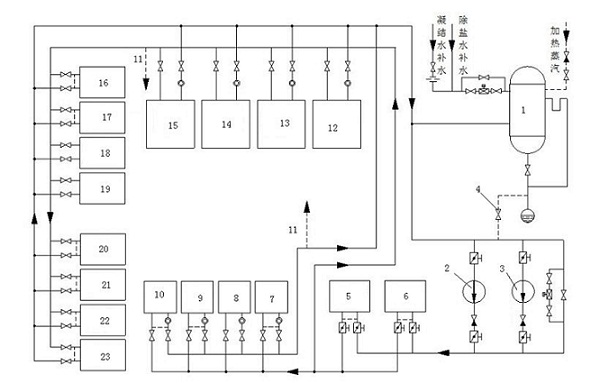

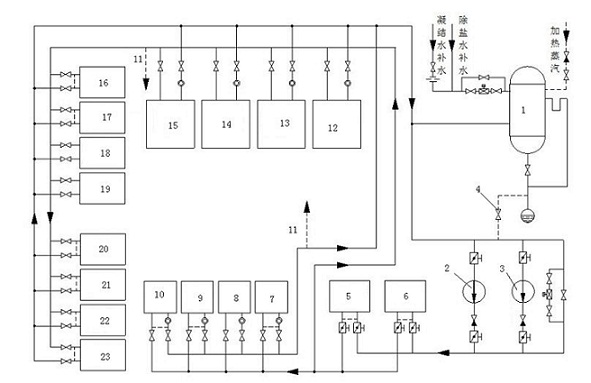

[0017] figure 1 Among them, it includes an expansion tank 1, and the expansion tank 1 communicates with the heating steam, and at the same time, the expansion tank 1 is also connected with desalinated water replenishment and condensed water replenishment through pipelines. The discharge pipe of the expansion tank 1 is connected to the closed water pump A2 and the closed water pump B3, and a section of pipeline and a control valve 4 for accelerating the water temperature increase are arranged between the discharge pipe of the expansion tank 1 and the inlets of the two closed water pumps for lifting and flushing Water temperature to 60°C. The two closed water pumps run in parallel and are respectively connected to the closed water cooler A5 and the closed water cooler B6 respectively. The outlet pipes of the two closed water coolers are divid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com