Reduction gear

A reducer and input shaft technology, applied in mechanical equipment, gear transmission, belt/chain/gear, etc., can solve the problems of the durability of the reducer, miniaturization of the reducer, and obstacles to high output, and achieve weight reduction. , The effect of alleviating stress concentration and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, an example of an embodiment of the present invention will be described in detail with reference to the drawings.

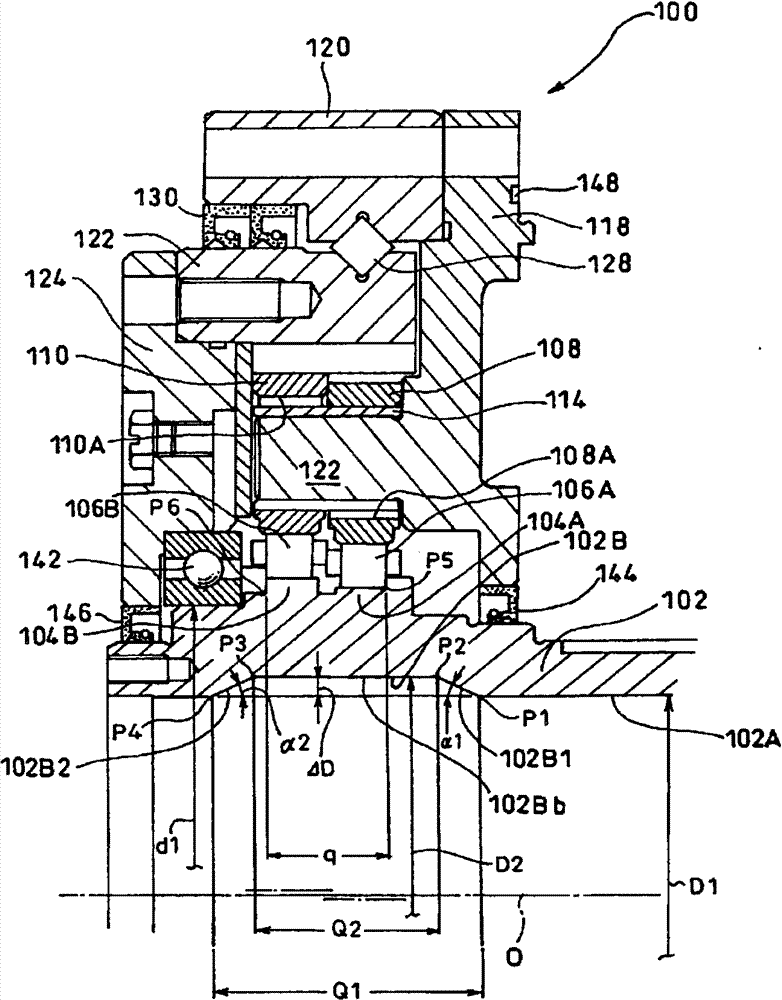

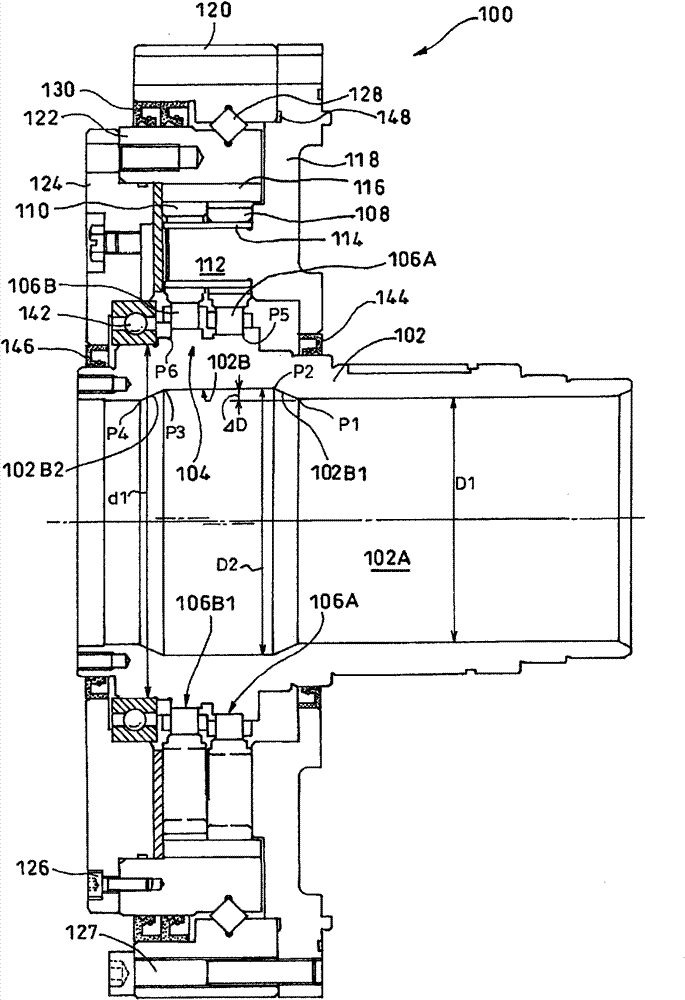

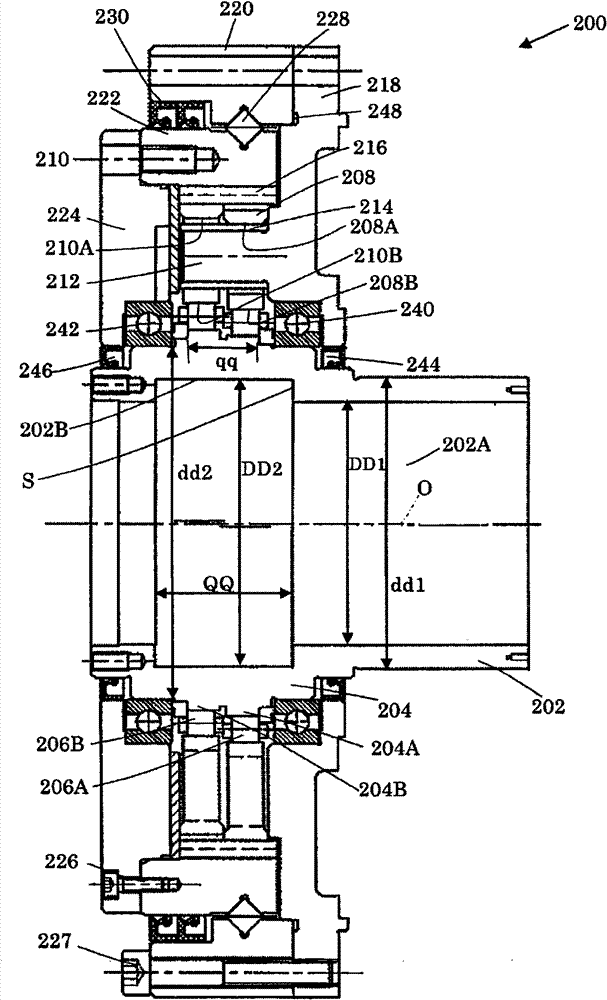

[0030] figure 2 It is a side sectional view of the speed reducer according to an example of the first embodiment of the present invention, figure 1 yes figure 2 An enlarged view of the main part.

[0031] The speed reducer 100 includes: an input shaft 102; first and second eccentric bodies 104A and 104B integrally provided on the input shaft 102; 2. External gears 108, 110; and an internal gear 122 internally meshing with the first and second external gears 108, 110. The input shaft 102 has a hollow portion 102A having an inner diameter D1, and recessed portions 102B are formed corresponding to axial positions where the first and second eccentric bodies 104A and 104B are formed. Describe in detail below.

[0032] The input shaft 102 is rotatably supported by a bearing 142 arranged in the vicinity of the second eccentric body 104B and a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com