battery cooling system

A cooling system and battery technology, applied in the direction of batteries, secondary batteries, battery pack components, etc., can solve the problems of insufficient and insufficient effect, and achieve the effect of effective heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

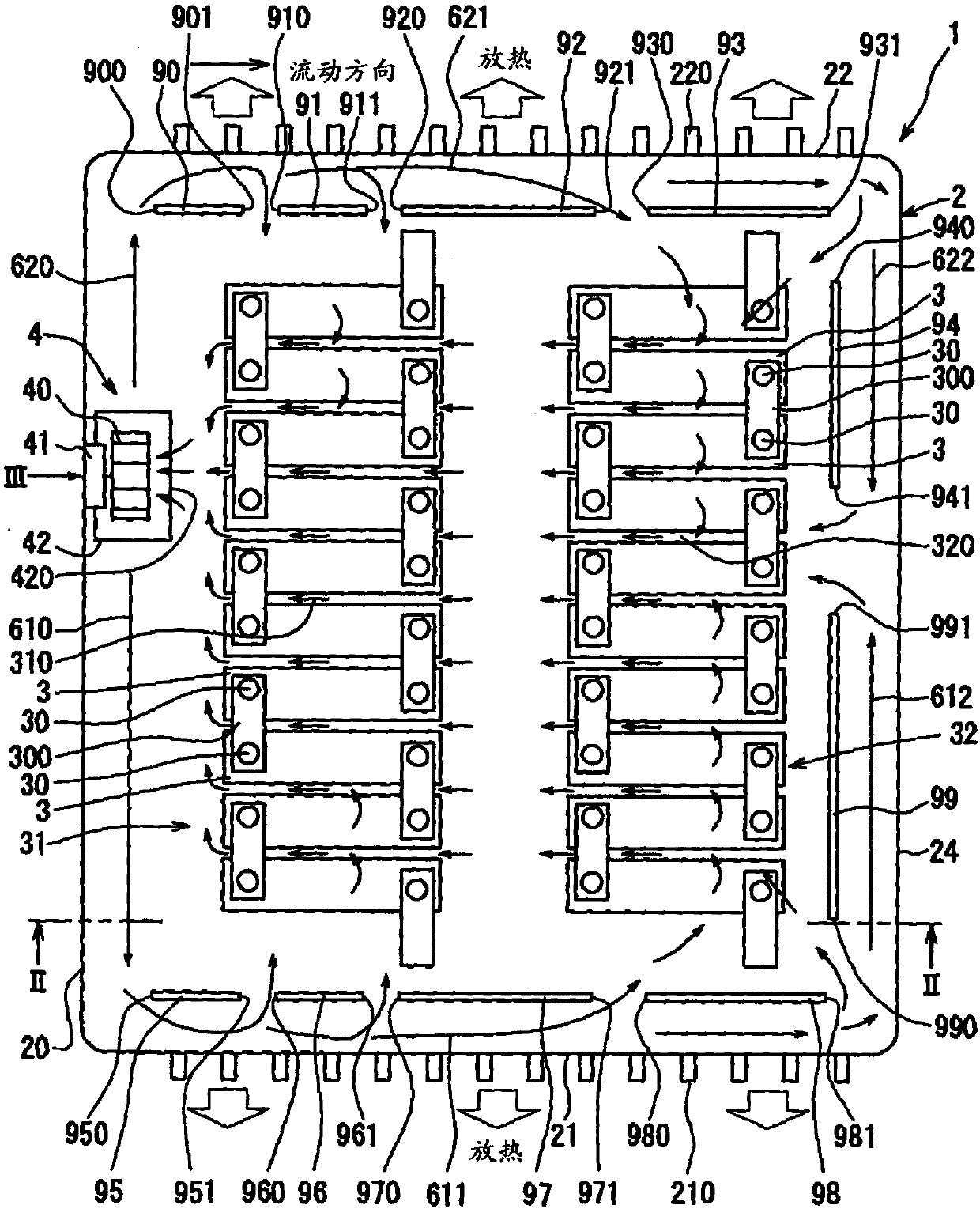

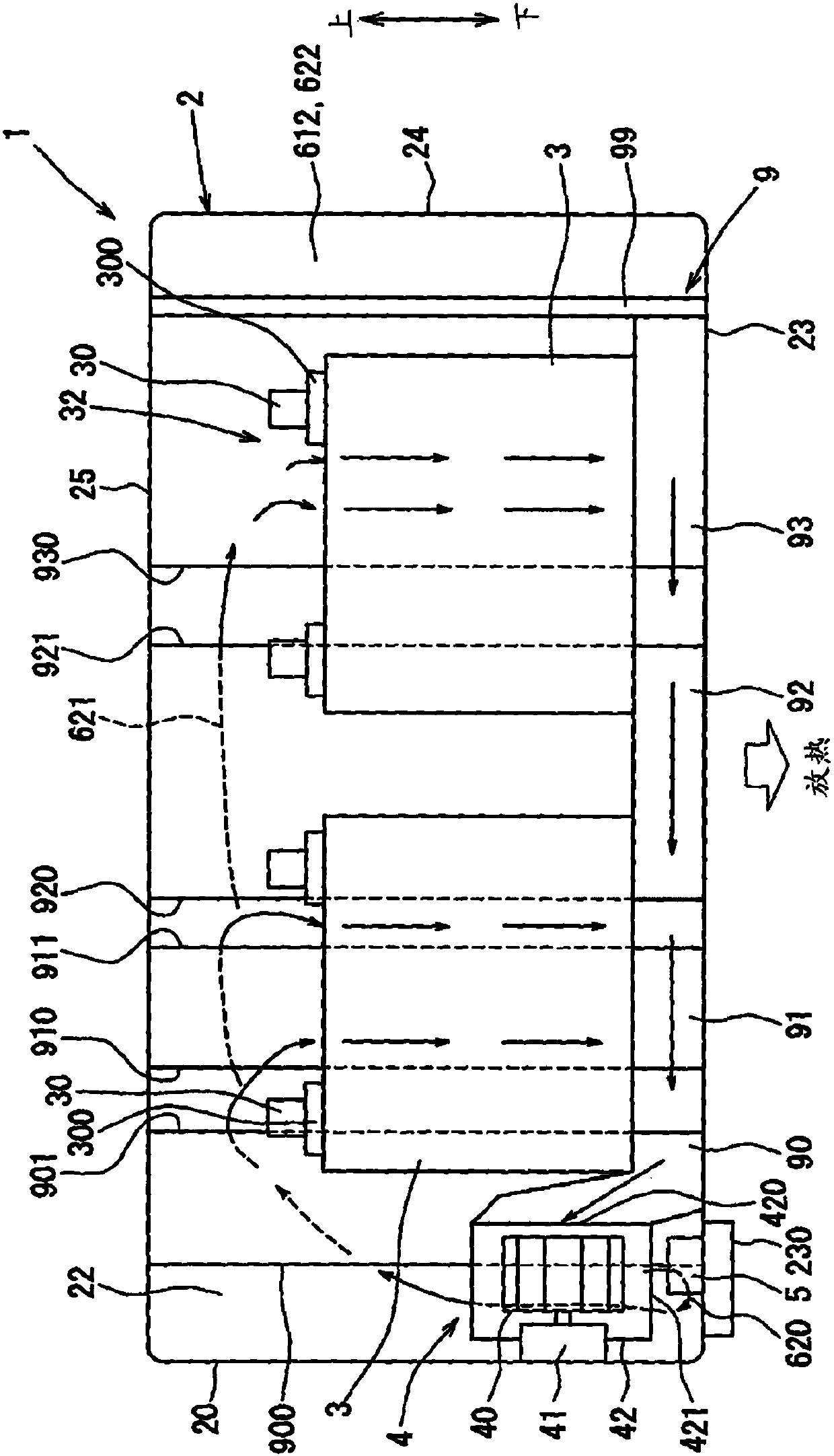

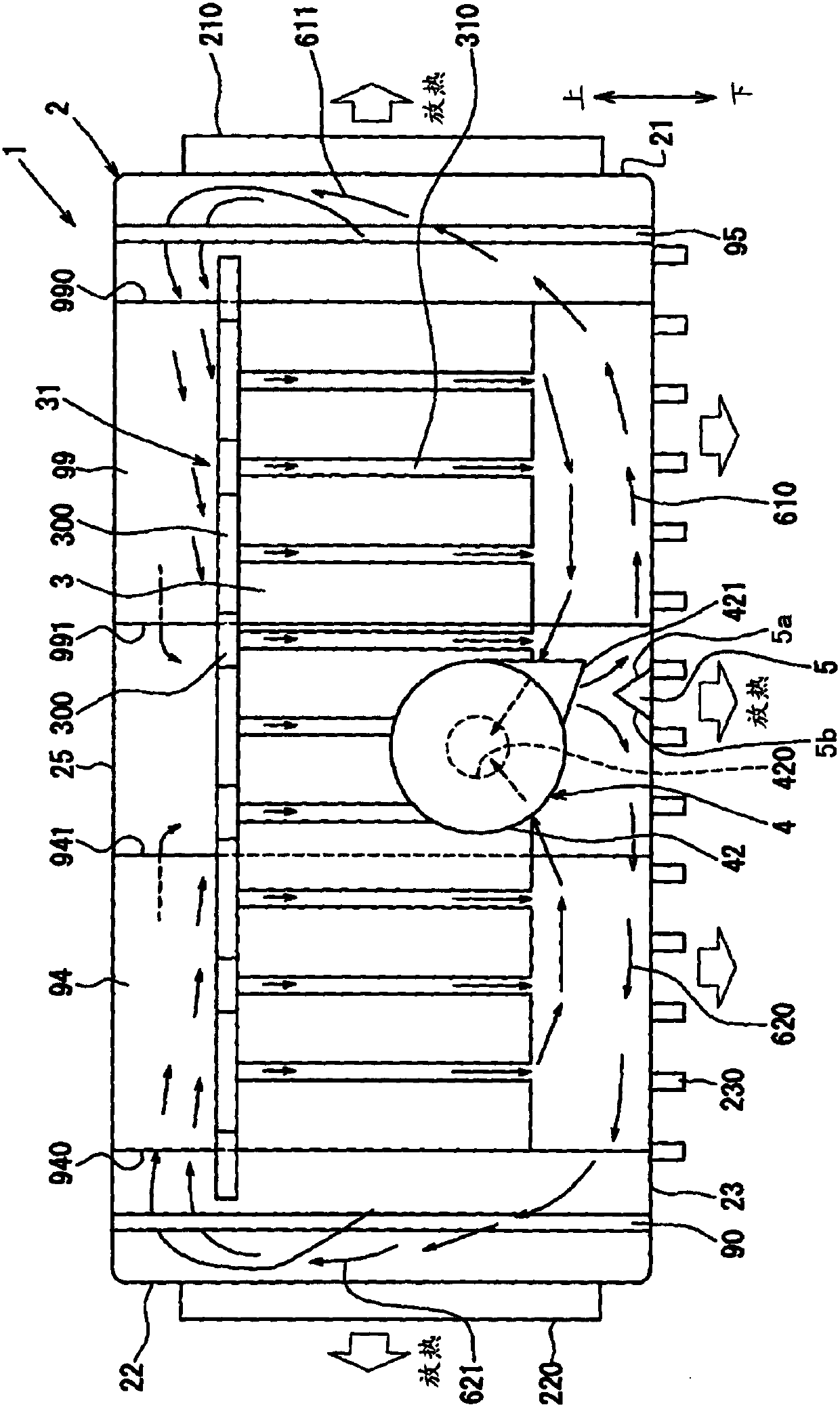

[0048] refer to Figure 1 to Figure 3 , the battery cooling system 1 related to the first embodiment of the present invention will be described below.

[0049] Figure 1 to Figure 3 is a schematic diagram showing the fluid flow for cooling the battery in the battery cooling system 1 and the composition of the interior of the housing 2 .

[0050] The battery cooling system 1 is used for a vehicle such as a hybrid car or an electric vehicle that uses an internal combustion engine and a motor as a driving source by combining an internal combustion engine and a motor driven by electric power charged in a battery, and an electric vehicle that uses, for example, A motor is used as a driving source.

[0051] The plurality of batteries included in the battery cooling system 1 may be, for example, nickel-metal hydride rechargeable batteries, lithium-ion rechargeable batteries, or organic compound batteries.

[0052] The battery cooling system 1 has a plurality of battery cells 3, a ...

no. 2 approach

[0280] Refer to the second embodiment Figure 4 and Figure 5 The passage forming member 109 is explained, which has a form different from that of the above-described embodiment.

[0281] exist Figure 4 and Figure 5In , components having the same composition as those of the first embodiment are given the same reference numerals, and have the same functions and effects.

[0282] In addition, the composition, function, and effect not particularly described in the second embodiment are the same as those of the above-mentioned embodiment.

[0283] Hereinafter, only differences from the above-described embodiment will be described.

[0284] The passage forming member 9 of the above-described embodiment may be replaced by a passage forming member 109 described below.

[0285] In a case forming a sealed space, the passage forming member 109 of the second embodiment is a component integrally formed with at least a single wall.

[0286] The passage forming member 109 is compose...

no. 3 approach

[0302] Refer to the third embodiment Figure 6 to Figure 8 The battery cooling system 101 will be described, which has a different form from the previous embodiments.

[0303] exist Figure 6 to Figure 8 In , components having the same composition as those of the first embodiment are given the same reference numerals, and have the same functions and effects.

[0304] In addition, the composition, function, and effect not particularly described in the third embodiment are the same as those of the foregoing embodiment.

[0305] Hereinafter, only points different from the foregoing embodiment will be described.

[0306] The passage forming member 109 of the second embodiment described above may be replaced by the passage forming member 9 of the third embodiment.

[0307] The battery cooling system 101 of the third embodiment also has fluid flow guiding units 7 , 8 .

[0308] The fluid flow guide unit 7, 8 is formed on one of the walls of the housing 2 forming the sealed space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com