Adhesive sheet, dicing tape-integrated adhesive sheet, film, method for manufacturing semiconductor device, and semiconductor device

A bonding sheet, semiconductor technology, applied in the direction of semiconductor/solid device manufacturing, semiconductor device, film/sheet adhesive, etc., can solve the problem of large amount of silver paste protruding, hindering chip miniaturization, and silver paste spreading And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0076] (Film 1)

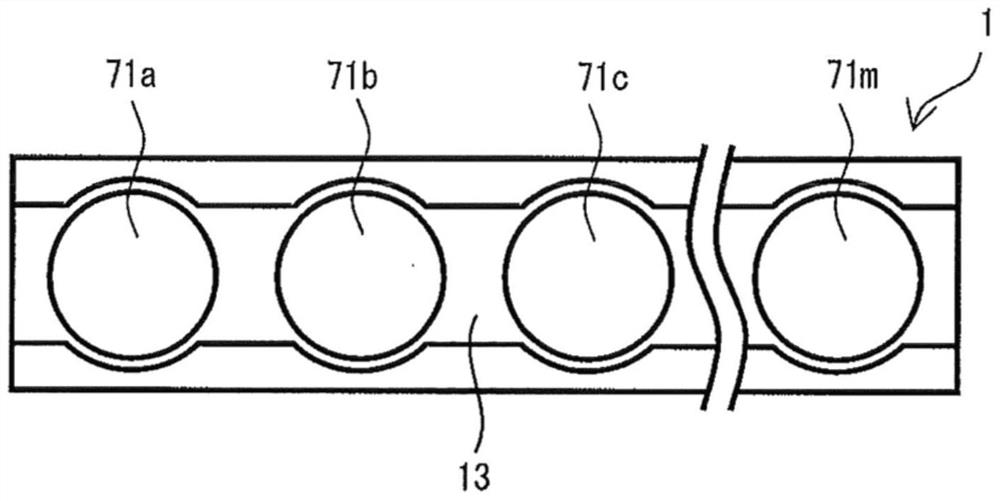

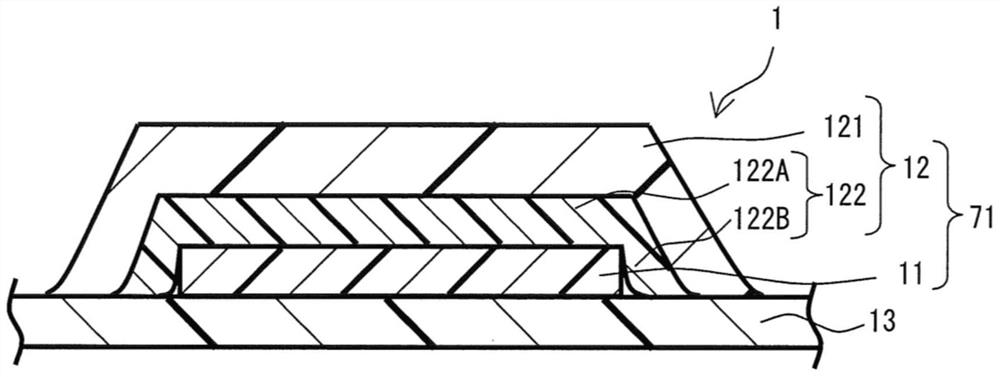

[0077] Such as figure 1 with figure 2 As shown, the film 1 includes a separator 13 and an adhesive sheet 11 arranged on the separator 13 . More specifically, the film 1 includes a separator 13 and dicing tape-integrated adhesive sheets 71 a , 71 b , 71 c , . The distance between the dicing tape-integrated adhesive sheet 71a and the dicing tape-integrated adhesive sheet 71b, the distance between the dicing tape-integrated adhesive sheet 71b and the dicing tape-integrated adhesive sheet 71c, ... the dicing tape-integrated adhesive sheet The distance between the adhesive sheet 71l and the dicing tape integrated adhesive sheet 71m is constant. The film 1 can be formed into a roll.

[0078] The dicing tape-integrated adhesive sheet 71 includes the dicing tape 12 and the adhesive sheet 11 arranged on the dicing tape 12 . The dicing tape 12 includes a base material 121 and an adhesive layer 122 arranged on the base material 121 . The adhesive sheet 11 can ha...

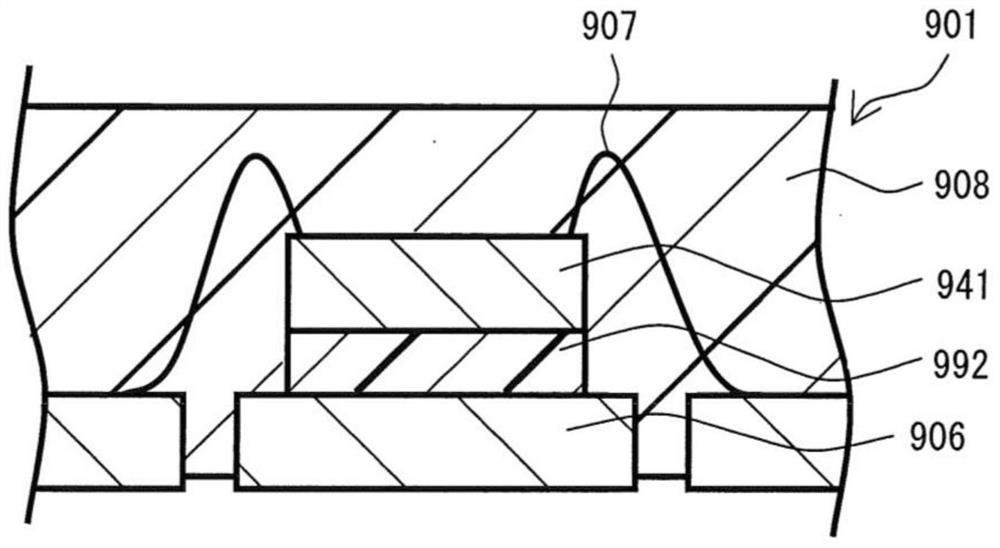

Deformed example 1

[0200] The contact portion 122A of the adhesive layer 122 has a property of being cured by radiation. The peripheral portion 122B of the adhesive layer 122 also has a property of being cured by radiation. In the manufacturing method of the semiconductor device, the chip 5 for die bonding is formed, the adhesive layer 122 is irradiated with ultraviolet rays, and the chip 5 for die bonding is picked up. Thereby, since the adhesive force of the adhesive layer 122 with respect to the chip|tip 5 for die bonding falls, it becomes possible to pick up the chip|tip 5 for die bonding easily.

Deformed example 2

[0202] The contact portion 122A of the adhesive layer 122 is cured by radiation. The peripheral portion 122B of the adhesive layer 122 is also cured by radiation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com