Semiconductor laser unit and optical pickup device

一种半导体、激光的技术,应用在半导体激光器、半导体器件、激光器等方向,能够解决困难、半导体激光单元制造工序复杂、粉尘污染等问题,达到实现特性安定、小型化可信度、容易组装的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

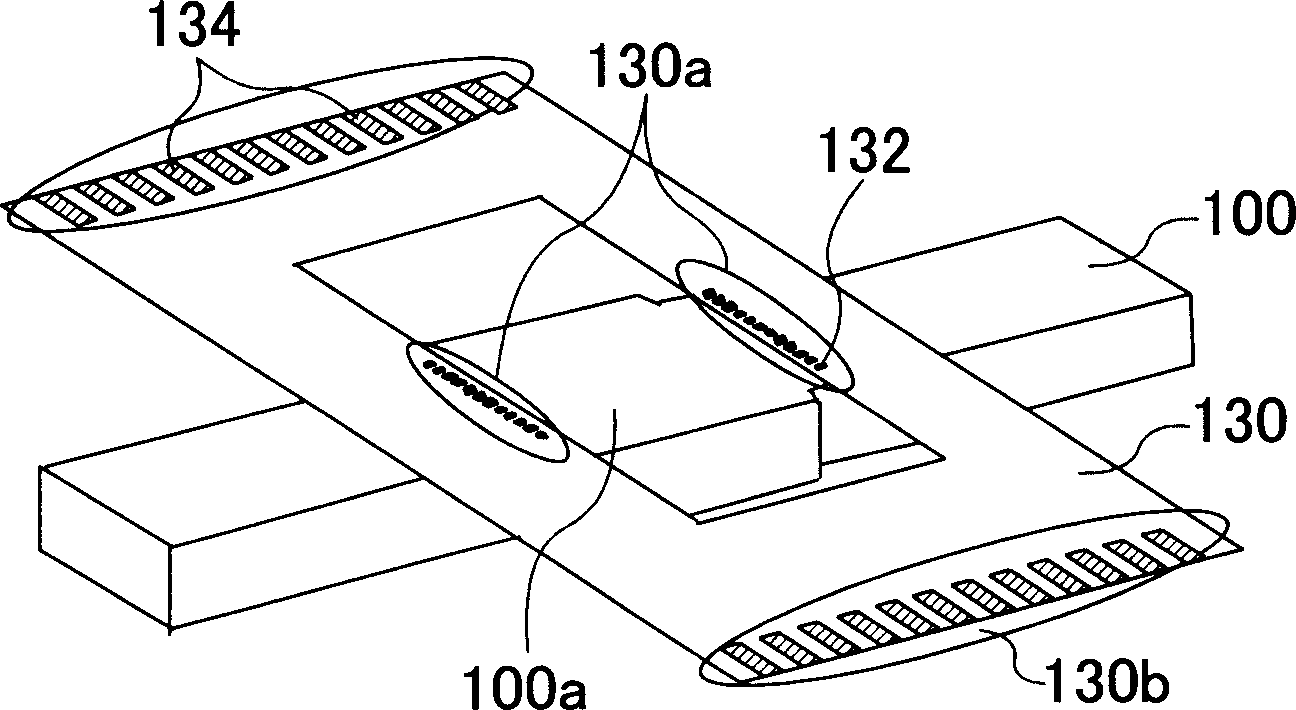

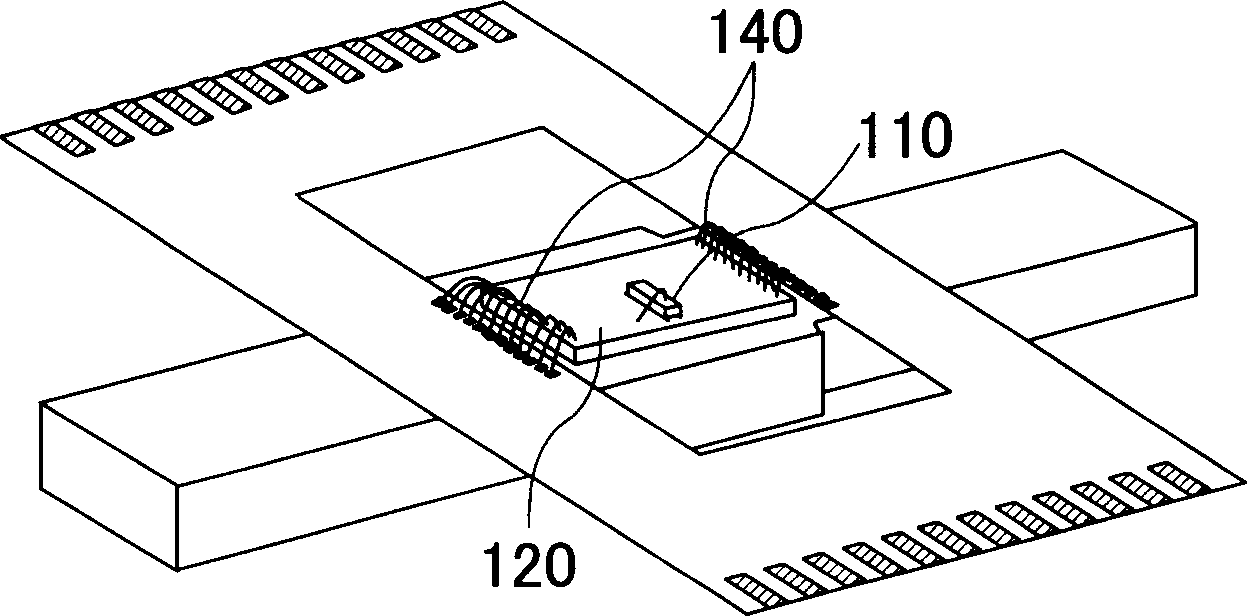

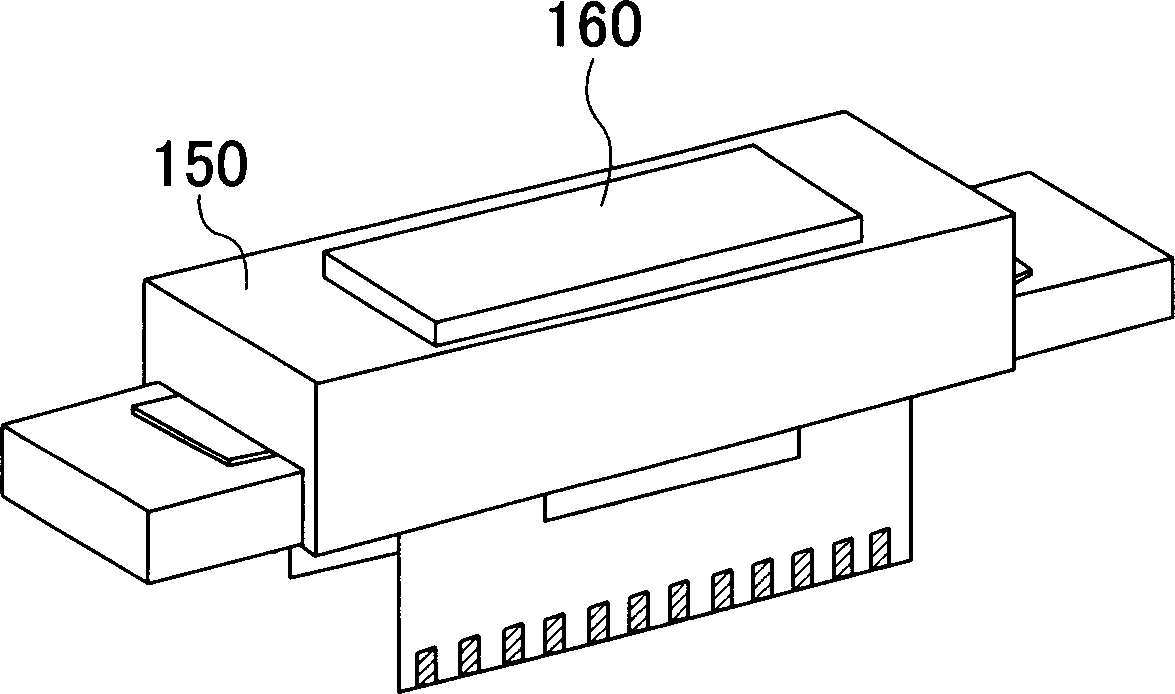

[0065] First, a semiconductor laser unit according to a first embodiment of the present invention will be described with reference to FIGS. 1 and 2 .

[0066] Figure 1(a) to Figure 1(c) , is a perspective view illustrating a method of manufacturing the semiconductor laser unit according to the first embodiment of the present invention. Fig. 2(a) is a top view showing the semiconductor laser unit according to the first embodiment. Fig. 2(b) is a side view showing the semiconductor laser unit according to the first embodiment.

[0067] The semiconductor laser unit of this embodiment has a simple structure that is easy to assemble, and it is easy to dissipate heat, and achieve high performance and miniaturization.

[0068] The semiconductor laser unit of this embodiment is assembled as follows.

[0069] First, as shown in FIG. 1( a ), a metal plate 100 made of copper or the like is prepared, and a flexible substrate 130 in which an opening is provided in the center is prepared...

no. 2 approach

[0097] Next, an optical pickup device according to a second embodiment of the present invention will be described with reference to FIG. 5 .

[0098] FIG. 5(a) is a top view of the optical pickup device 500 of this embodiment. FIG. 5( b ) is a cross-sectional view of the optical pickup device 500 .

[0099] The optical pick-up device 500 of the present embodiment comprises: collimator 510; Mirror 520; Objective lens 530; The semiconductor laser unit 540 involved in the first embodiment; The heat release block 550 is bonded and fixed with a silicon-based thermally conductive adhesive. The laser light emitted from the semiconductor laser unit 540 irradiates the optical disc 570 through the collimating mirror 510 , the reflecting mirror 520 , and the objective lens 530 . The reflected light reflected from the optical disc 570 enters the semiconductor laser unit through the same optical path.

[0100] The wiring connection between the outside of the flexible substrate of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com