Automatic assembling machine for lotion pump

An automatic assembly machine and lotion pump technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency, low precision, and a lot of manpower in manual assembly, saving manpower, high processing accuracy, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A further detailed description will be made below in conjunction with the accompanying drawings and embodiments of the present invention:

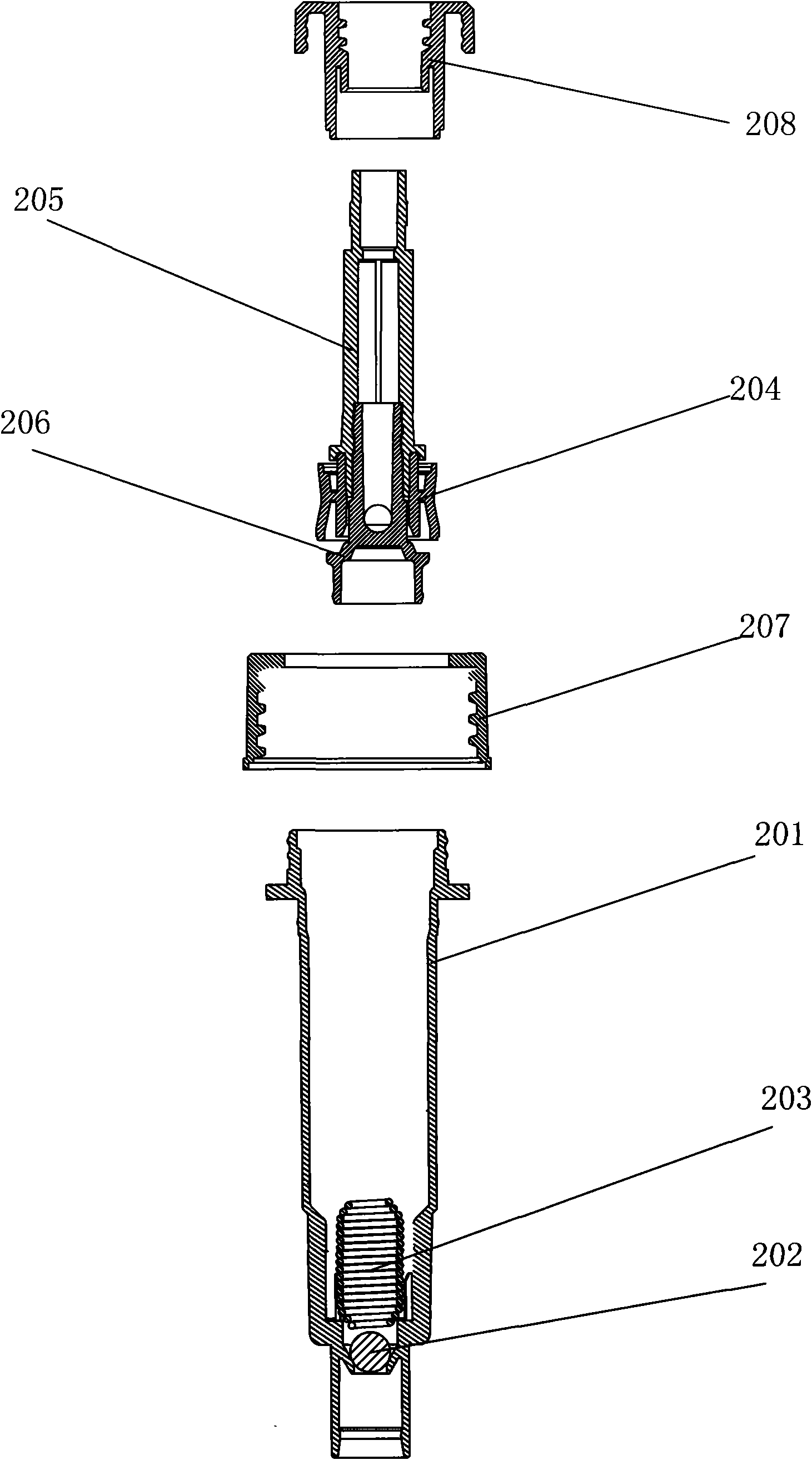

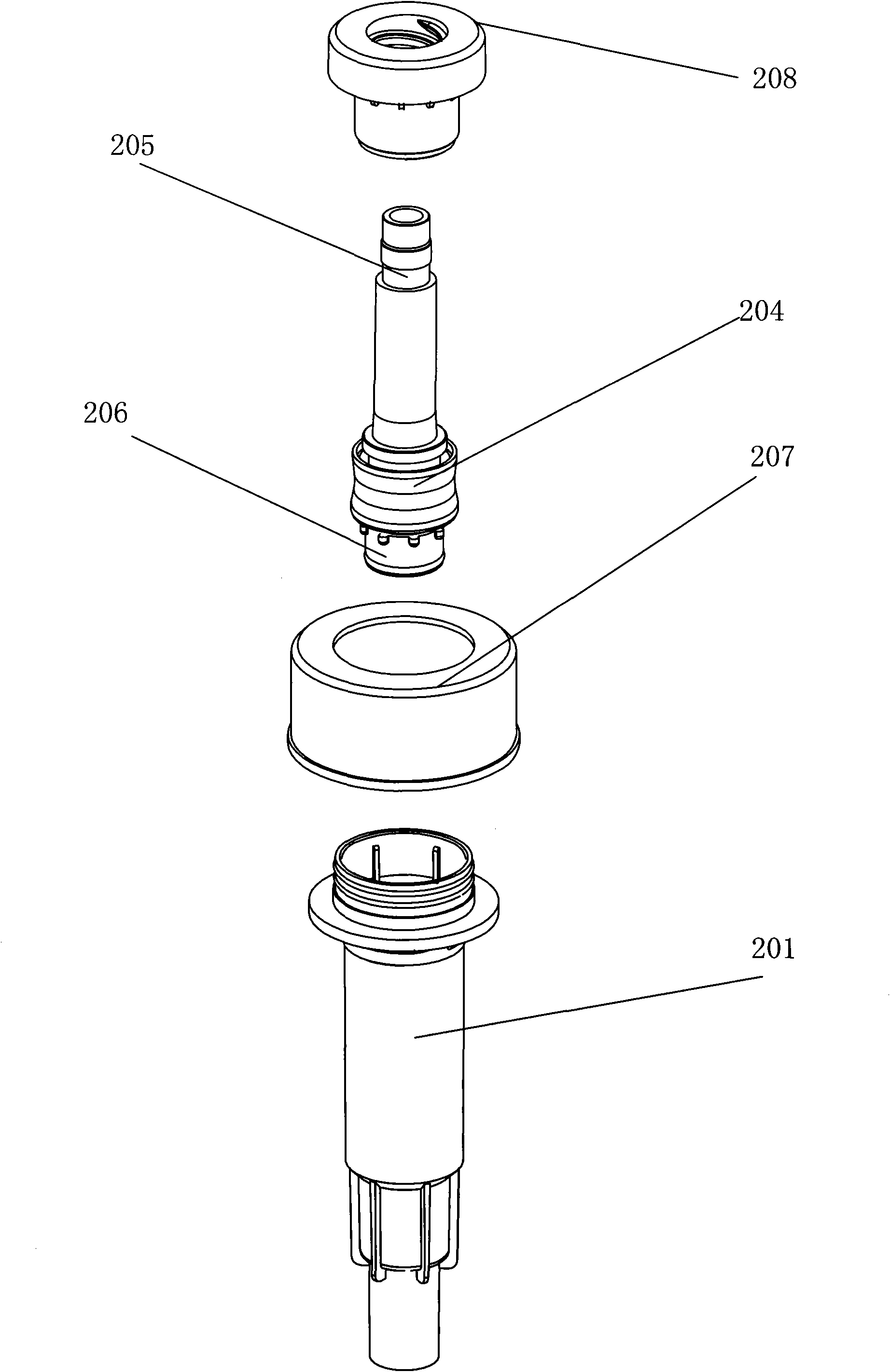

[0032] The invention introduces an automatic assembling machine for lotion pump, which can be assembled as figure 1 , 2 The lotion pump shown includes a pump casing 201, a pump bead 202 installed in the pump casing 201, a spring 203, a suction plug 204, an upper pump rod 205, a lower pump rod 206, and a cover on the pump casing 201. Lock bottle cap 207 and lock cap 208. In the assembly machine of the present invention, during the process of press-assembling the lotion pump, the pump beads 202 and the spring 203 are put into the pump housing 201 and then fed together, and the upper pump rod 205 and the lower pump rod 206 are inserted on the suction plug 204 to feed together, Lock bottle cap 207 and lock cap 208 feed separately.

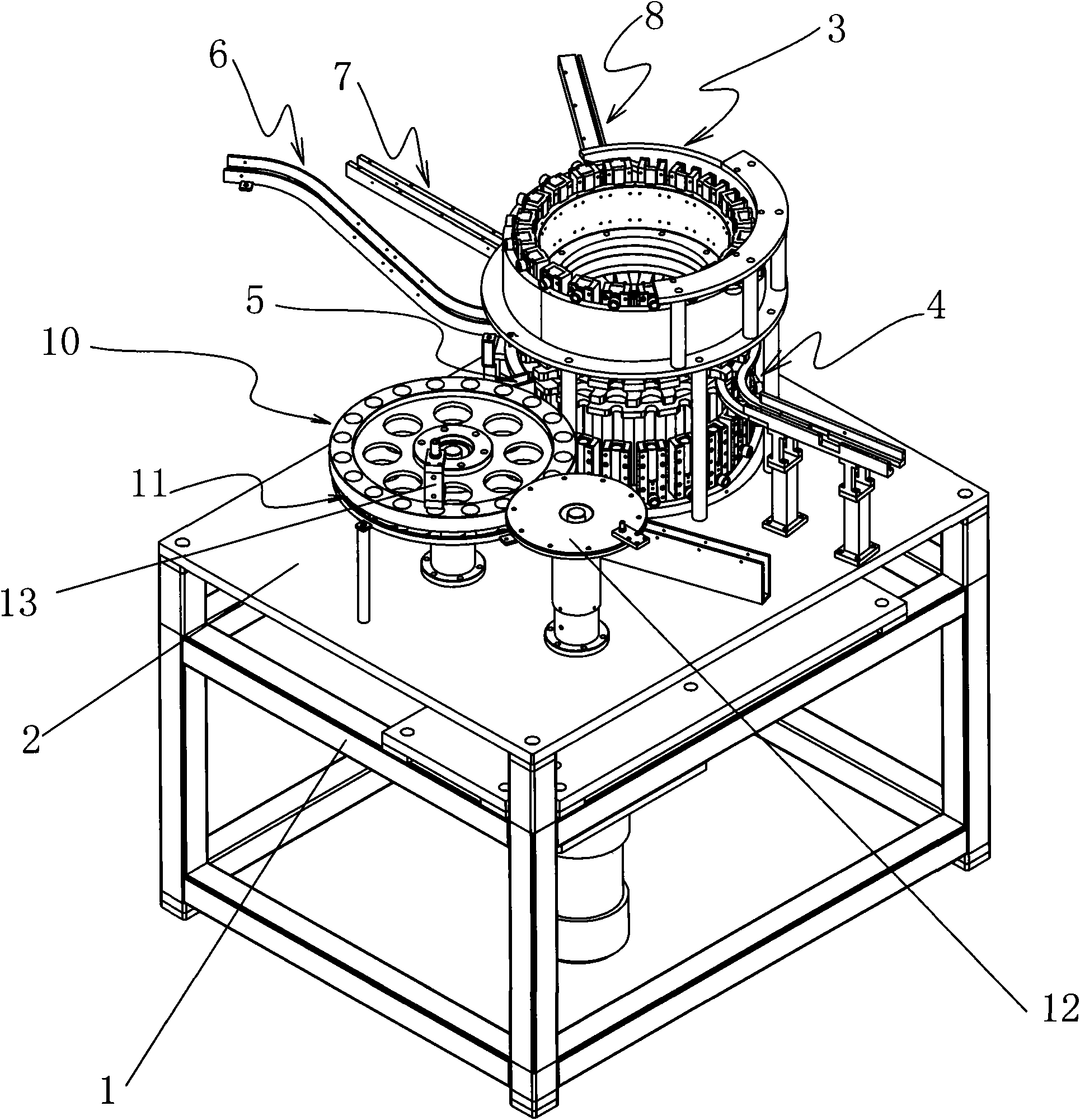

[0033] see Figure 2-8 As shown, the assembling machine of the present invention includes a frame 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com