Magnetic drive unit and a drive actuating mechanism with same

A magnetic drive and actuator technology, applied in the direction of electromagnets, electrical components, three-dimensional systems, etc., can solve the problems of drive execution efficiency, poor response sensitivity, low mechanism drive efficiency, and difficult micro-miniature structures, etc., to achieve drive High efficiency, simple structure, and large driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

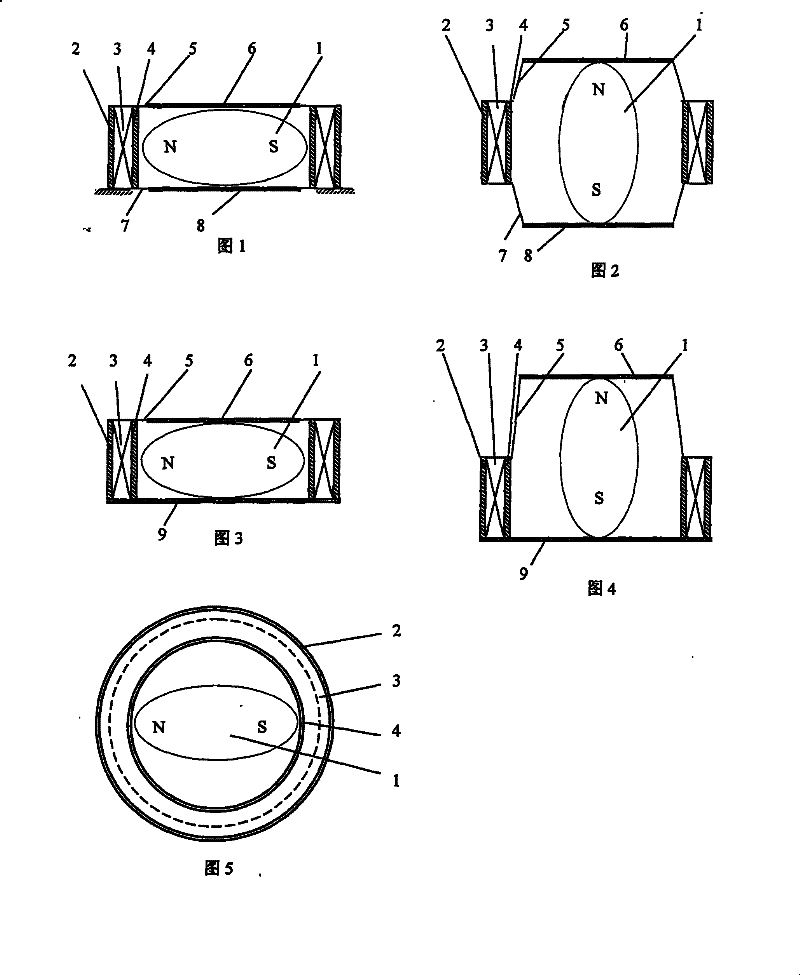

Embodiment 1

[0039] Such as figure 1 , figure 2 As shown, the magnetic drive unit includes a direction-shaped permanent magnet 1, an outer frame 2, an electromagnetic coil 3, an inner frame 4, an upper elastic membrane body 5, an upper rigid module 6, a lower elastic membrane body 7 and a lower rigid module 8; The frame 2 and the outer frame 4 are fixed and are cylindrical; the electromagnetic coil 3 is placed inside the outer frame 2 and wound outside the inner frame 4, and the permanent magnet 1 is freely placed on the upper surface covered by the inner frame 4 and the upper and lower end surfaces. In the cavity formed by the elastic membrane body 5 and the lower elastic membrane body 7; in addition, the upper rigid module 6 and the lower rigid module 8 are bonded to the upper elastic membrane body 5 and the lower elastic membrane body 7 respectively.

[0040] Wherein, the permanent magnet 1 is a permanent magnet ellipsoid particle with the longest length in the N-S direction of the ma...

Embodiment 2

[0043] Such as image 3 , Figure 4 As shown, the upper side of the inner frame 4 is provided with an upper elastic membrane body 5, and the lower side is fixed with a rigid baffle 9, and the others are the same as in Embodiment 1. During the working process of electromagnetic excitation, due to the support of the rigid baffle 9, the permanent magnet 1 has an overall upward lifting action process while rotating, and all the deformation of the permanent magnet 1 in the direction of the electromagnetic field is transferred to the upper part. The elastic membrane 5 and the upper rigid module 6 make the magnetic drive unit only exhibit one-way or one-sided expansion and contraction action.

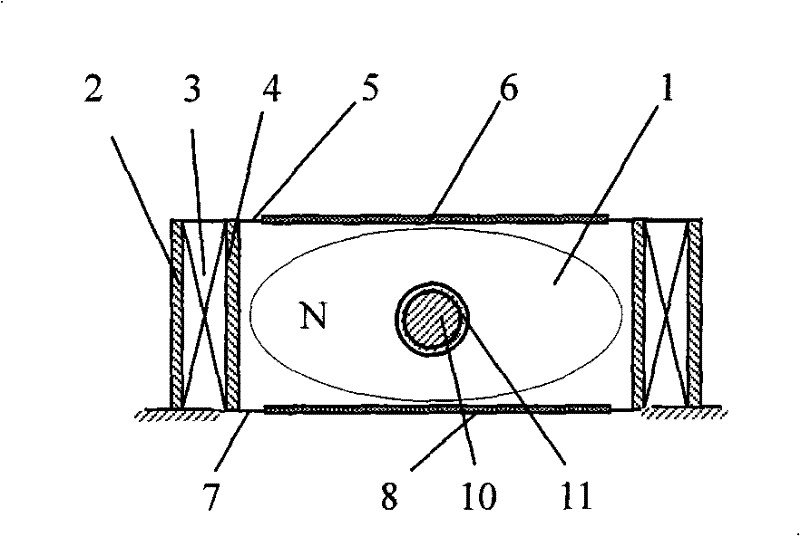

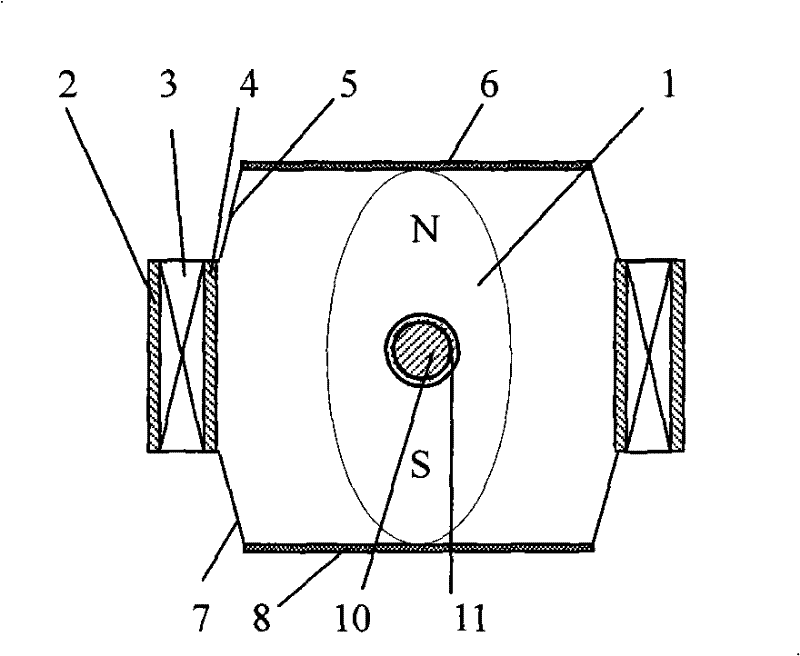

Embodiment 3

[0045] Such as Figure 6 , Figure 7 As shown, it includes a direction-shaped permanent magnet 1, an outer frame 2, an electromagnetic coil 3, an inner frame 4, an upper elastic membrane body 5, an upper rigid module 6, a lower elastic membrane body 7 and a lower rigid module 8; the inner and outer frames 2, 4 Fixed, the electromagnetic coil 3 is placed inside the outer frame 2 and wound outside the inner frame 4, the center of the permanent magnet 1 is drilled to assemble a bearing 11, the middle of the bearing 11 penetrates a rotating support rod 10, and the two ends of the rotating support rod 10 Placed in a chute 12 fixed on the inner frame 4. In this case, the permanent magnet 1 and the rotating support rod 10 are placed in the cavity formed by the upper elastic membrane body 5 and the lower elastic membrane body 7 covered by the inner frame 4 and the upper and lower end faces; in addition, the upper elastic membrane body 5. The upper module body sheet 6 and the lower m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com