Oil supply device for linear compressor

A technology of linear compressor and oil supply device, applied in mechanical equipment, machine/engine, liquid variable capacity machinery, etc., to achieve the effect of improving oil supply capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

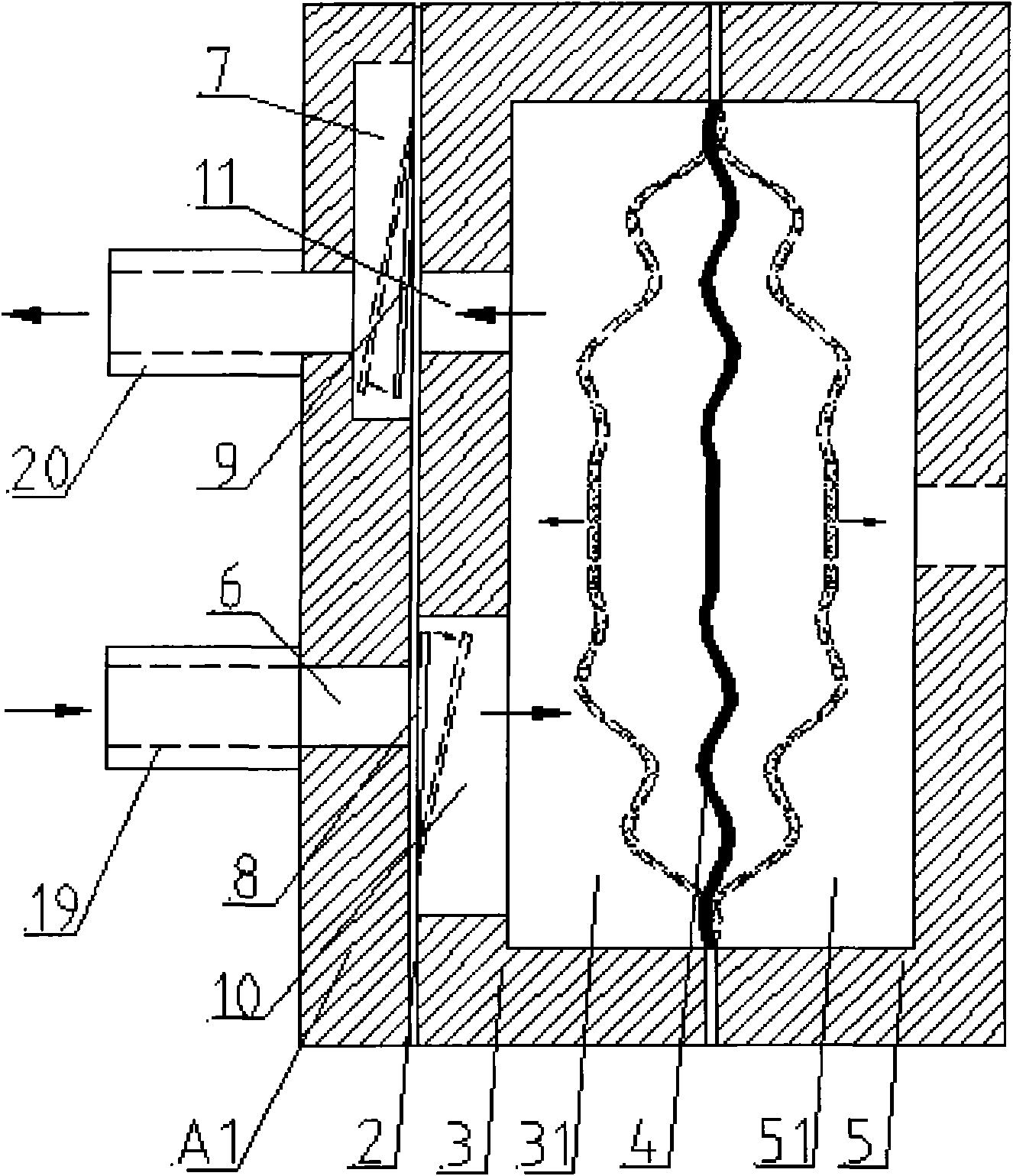

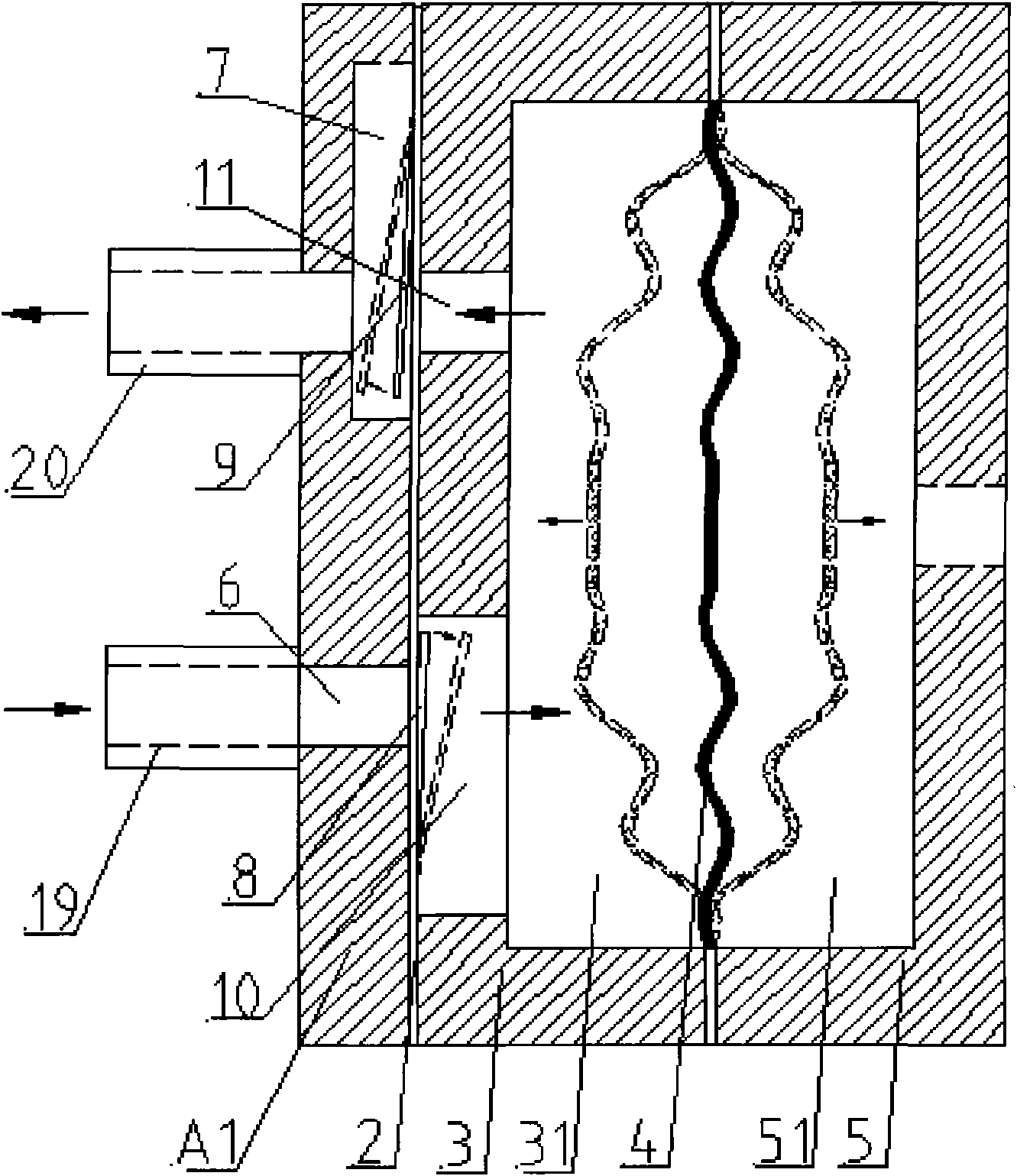

[0029] figure 1 It is a schematic diagram of the structure and principle of the linear compressor oil supply device (an embodiment) of the present invention; it can be seen from the figure that the linear compressor oil supply device provided by the present invention provided in Embodiment 1 includes:

[0030] A first groove 3 and a second groove 5 that interlock an elastic film 4 between the two; and a left end cover that covers the outer surface of the bottom of the first groove 3 A1;

[0031] The first groove 3 and the elastic membrane 4 enclose a first cavity 31; the second groove 5 and the elastic membrane 4 enclose a second cavity 51;

[0032] The bottom of the first groove 3 is provided with an oil supply through hole 11 and an oil suction through groove 10; the first end cover 1 is provided with an oil supply blind groove 7 with an open end and an oil suction through hole 6;

[0033] The oil-suction hole 6 communicates with the oil-suction groove 10; the oil-suction ...

Embodiment 2

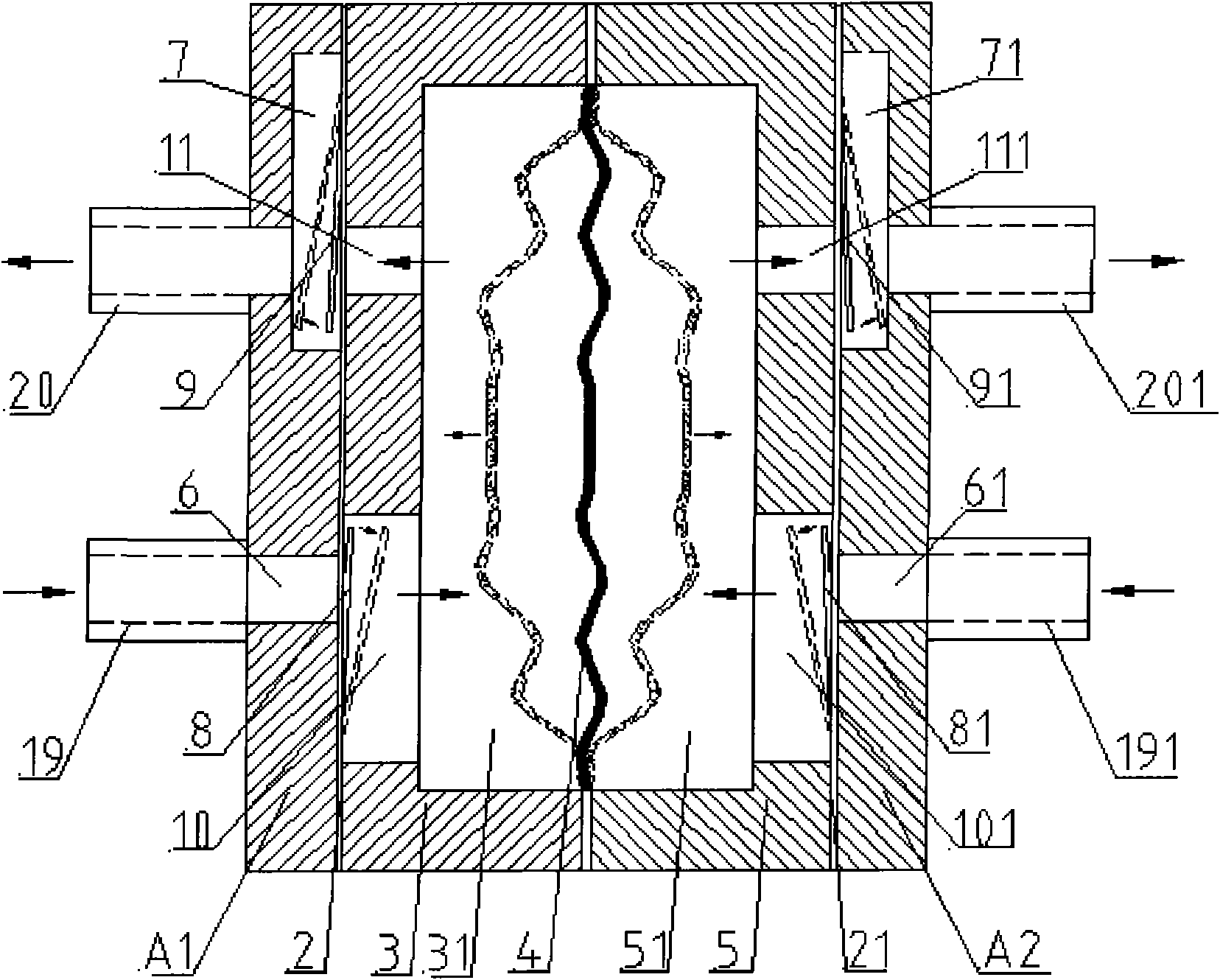

[0042] figure 2It is a schematic diagram of the structure and principle of the linear compressor oil supply device (another embodiment) of the present invention; it can be seen from the figure that the linear compressor oil supply device provided by the present invention includes the structure described in Embodiment 1 In addition, it may further include a right end cover A2 covering the outer surface of the bottom of the second groove 5;

[0043] The bottom of the second groove 5 is provided with an oil supply through hole 111 and an oil suction through groove 101; the first end cover 1 is provided with an oil supply blind groove 71 with an open end and an oil suction through hole 61;

[0044] The oil-suction through hole 61 communicates with the oil-suction through-groove 101; a one-way oil-suction valve 81 is installed on the end face of the oil-suction through-hole 61 connected with the oil-suction through-groove 101; The direction of the second cavity 51 is opened;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com