A rotary mechanical oil pump structure, a compressor oil pump structure and a rotary compressor

A technology for compressor pumps and rotating machinery, applied in the field of compressors, to achieve the effects of improving oil supply capacity, simple structure, and ensuring lubricating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

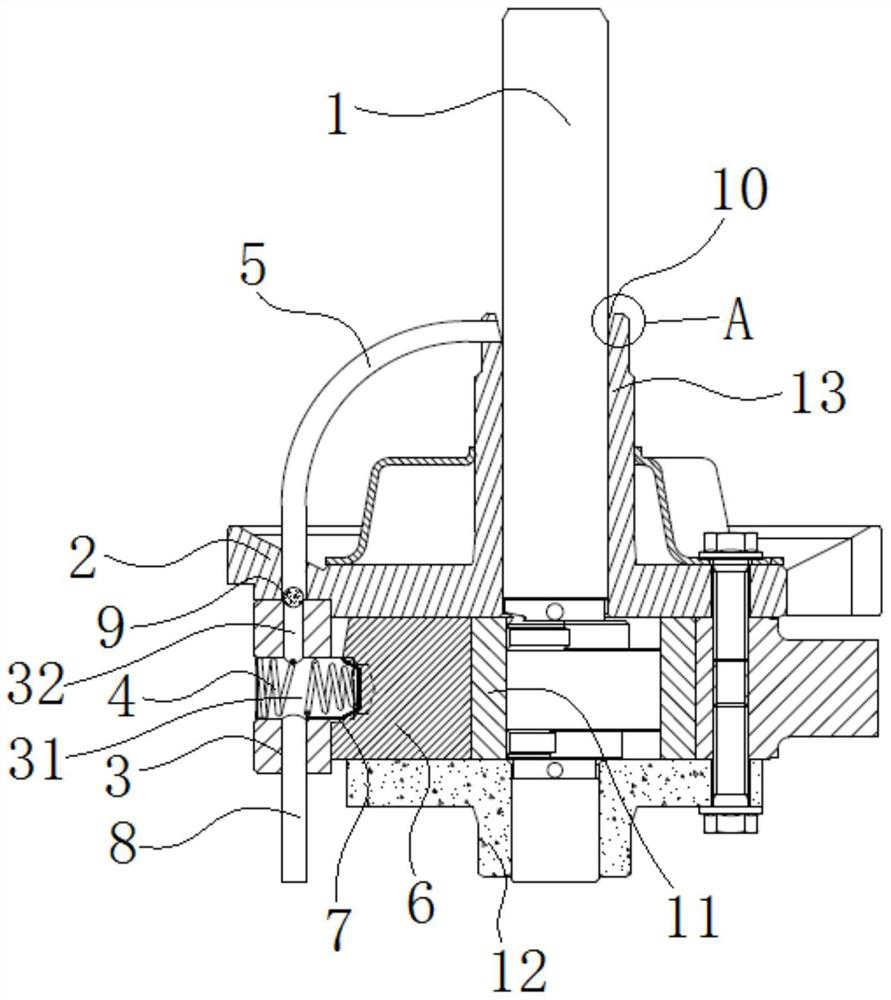

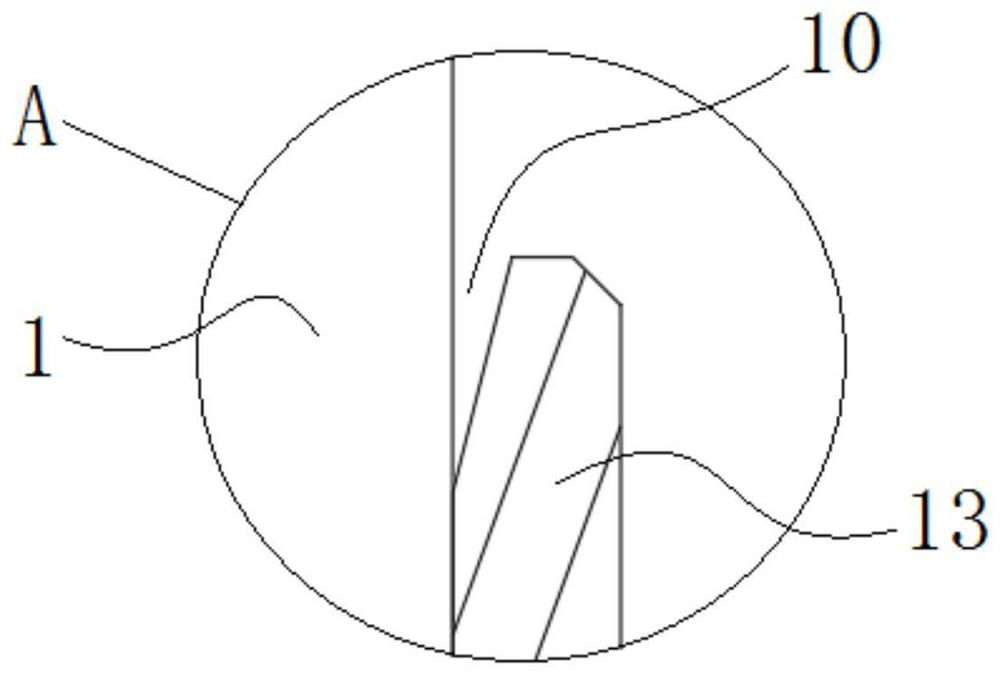

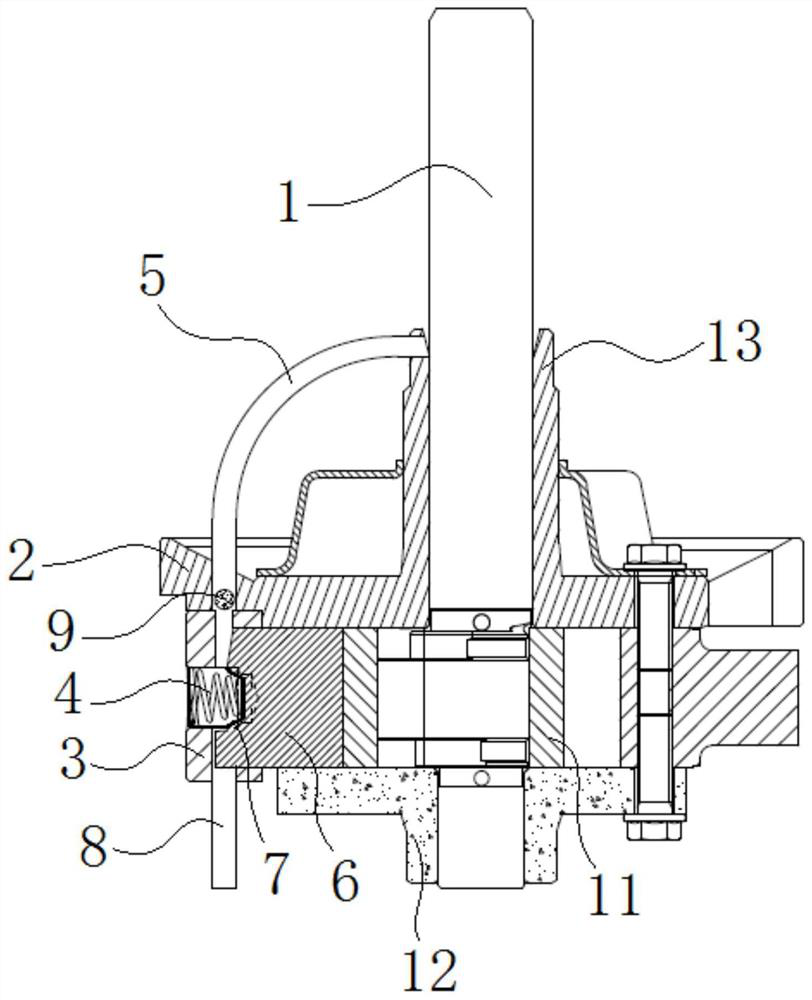

[0031] Such as Figure 1 to Figure 3 As shown, the present invention provides a rotary mechanical oil pumping structure, including a cylinder 3, a driving mechanism and moving parts; wherein, the moving parts can reciprocate in the cylinder under the action of the driving mechanism; an oil pumping cavity is formed in the cylinder 31. The oil pump chamber 31 is connected upward to an oil pipe 5, and the other end of the oil pipe 5 is connected to the lubricating part of the rotating machine; the volume of the oil pump chamber 31 can change periodically with the reciprocating motion of the moving parts; to drive the moving parts to do reciprocating motion, so that the moving parts squeeze the pump oil chamber to discharge or absorb oil; further, the pump oil chamber 31 is connected downward to the lower oil pipe 8, and the other end of the lower oil pipe 8 extends into the oil pool In, oil can be absorbed.

[0032] Preferably, in combination with the above schemes, such as Fi...

Embodiment 2

[0035] Such as Figure 1 to Figure 3 As shown, the present invention provides a compressor oil pump structure, specifically we take a vane compressor as an example.

[0036] Such as Figure 1 to Figure 3 As shown, the oil pumping structure of the compressor includes a driving mechanism, a cylinder 3, an upper oil pipe 5 and moving parts, and the moving parts in this embodiment are slide plates 6 . The rotor is eccentrically arranged in the cylinder, and the preferred rotor is provided with a number of longitudinal grooves, in which slides that can slide freely in the radial direction are installed, and the rotor rotates once, and the slides reciprocate once.

[0037] Further, the cylinder 3 of the present invention is provided with an oil pump chamber 31, one end of the upper oil pipe 5 communicates with the oil pump chamber 31, and the other end of the upper oil pipe 5 communicates with the lubricating part of the compressor; the volume of the oil pump chamber 31 can be The...

Embodiment 3

[0046] In combination with the above scheme, the present invention also provides a rotary compressor, which adopts a compressor oil pump structure; the compressor oil pump structure is the above-mentioned compressor oil pump structure; specifically, the rotary compressor is a rotor compression machine, specifically preferably a vane or vane compressor or hinged compressor.

[0047] Adopt above-mentioned scheme, make the present invention have following technical effect:

[0048] First, the compressor oil pump structure provided by the present invention can solve the problems of difficult low-frequency oil pumping, insufficient low-frequency lubrication, and easy wear of existing compressors, so that the height of the compressor oil pump is no longer affected by the operating frequency of the compressor;

[0049] Second, the compressor oil pump structure provided by the present invention improves the radial oil supply capacity of the compressor pump oil and expands the oil pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com