Diesel roller pump for passenger vehicles

A technology for roller pumps and passenger cars, applied in the field of roller pumps, can solve problems such as shortening service life and increasing oil supply capacity, and achieves the effect of prolonging service life, satisfying use requirements and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

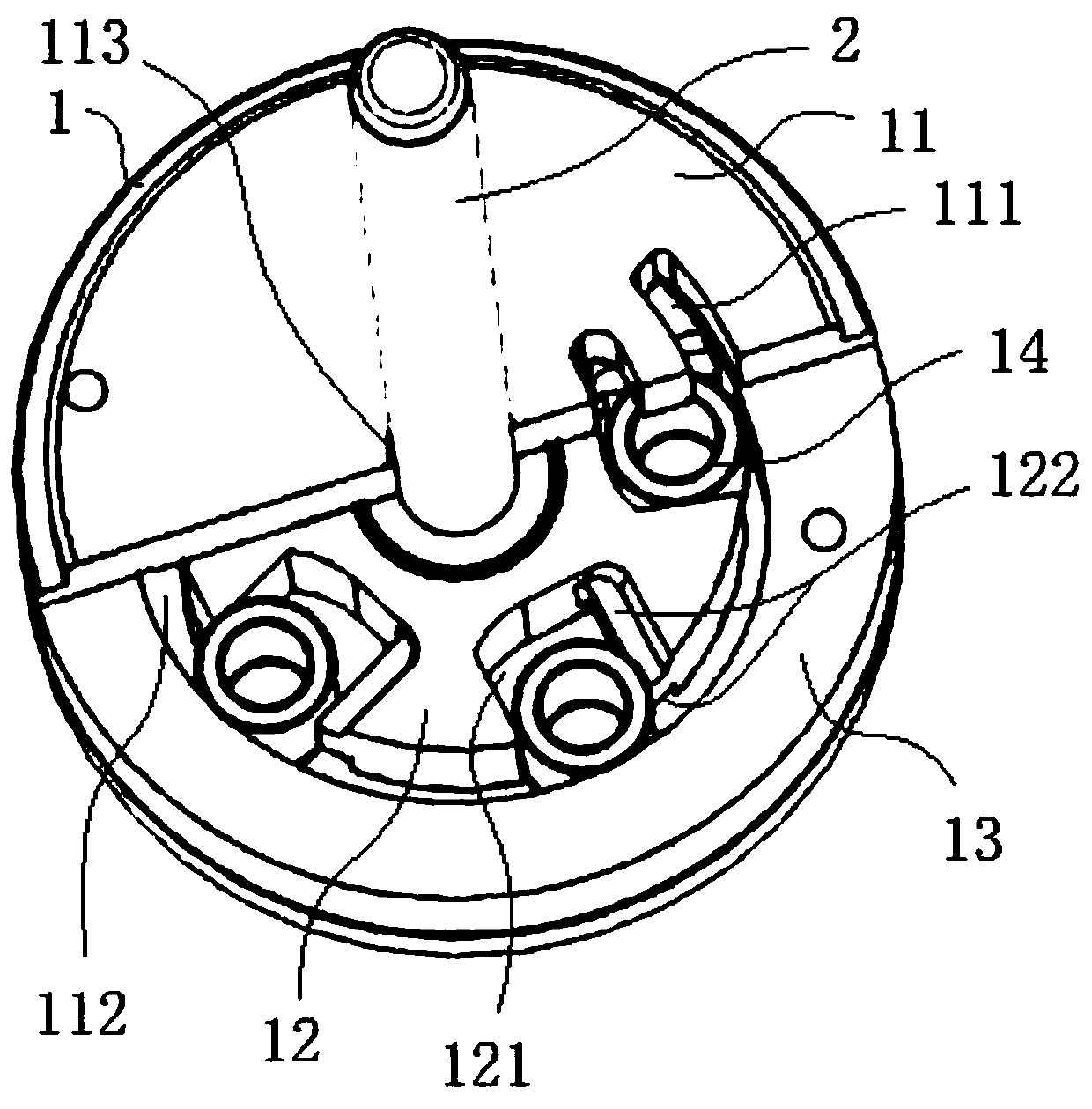

[0019] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 The technical solutions provided by the present invention are described in detail, but the following content is not intended as a limitation of the present invention.

[0020] figure 1 It is a structural diagram of an embodiment of a passenger vehicle diesel roller pump of the present invention. Such as figure 1 As shown, the passenger car diesel roller pump provided in this embodiment includes: a housing, a motor component and a pump body component 1, wherein the motor component and the pump body component 1 are both arranged in the housing and located at both ends of the housing At the same time, the pump body part 1 is power-connected with the armature shaft 2 of the motor part, so that the pump body part 1 is driven by the armature shaft 2 of the motor part, thereby realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com