Connector

A technology of contact parts and terminals, which is applied in the direction of connection, parts of connection devices, and devices for preventing wrong connections, etc. It can solve the problems that the brake 40 cannot work smoothly, the overall weight of the joint increases, and the specificity of the terminal group is large, so as to prevent contact. , prevent mis-insertion, and improve durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

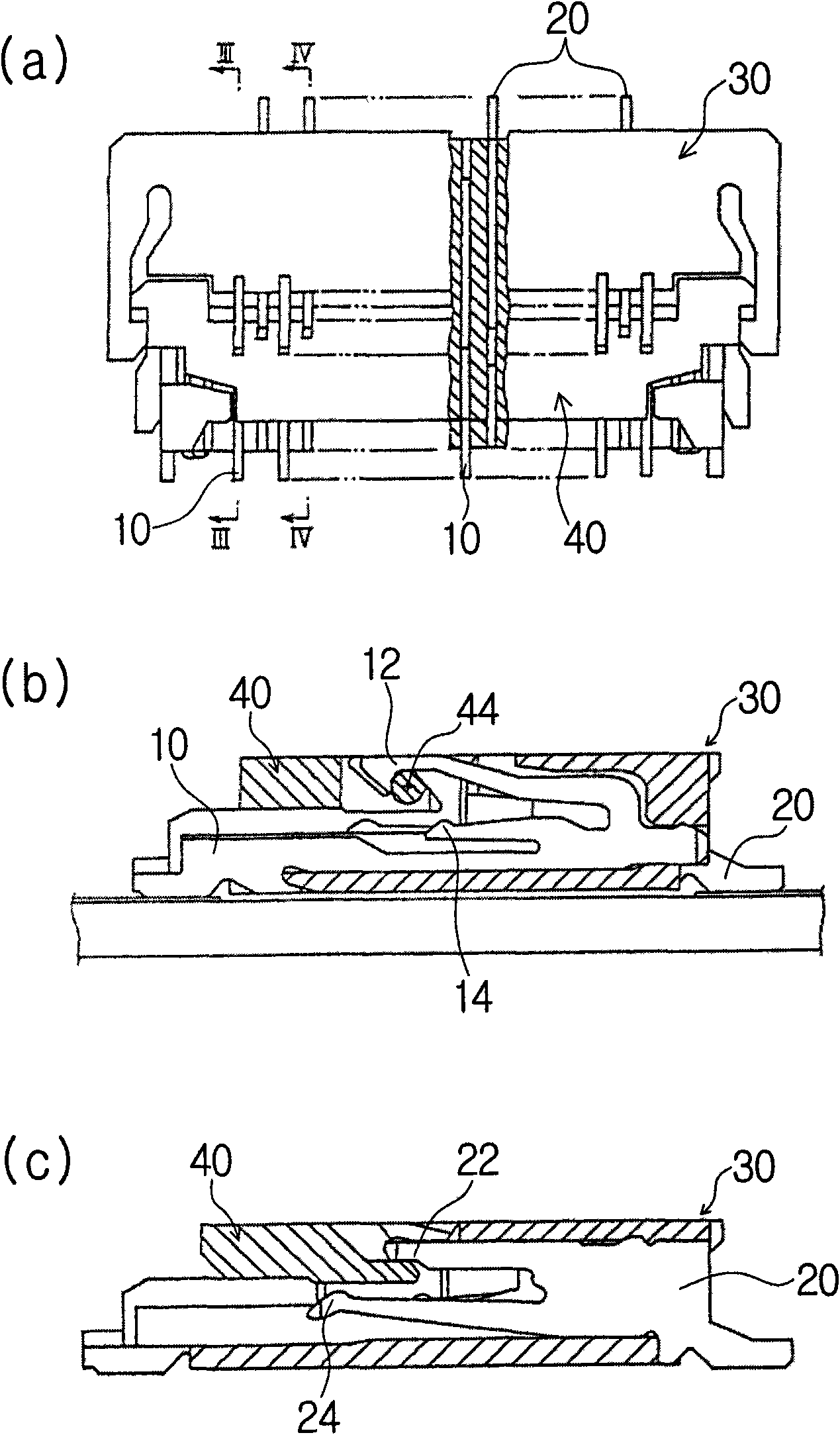

[0026] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

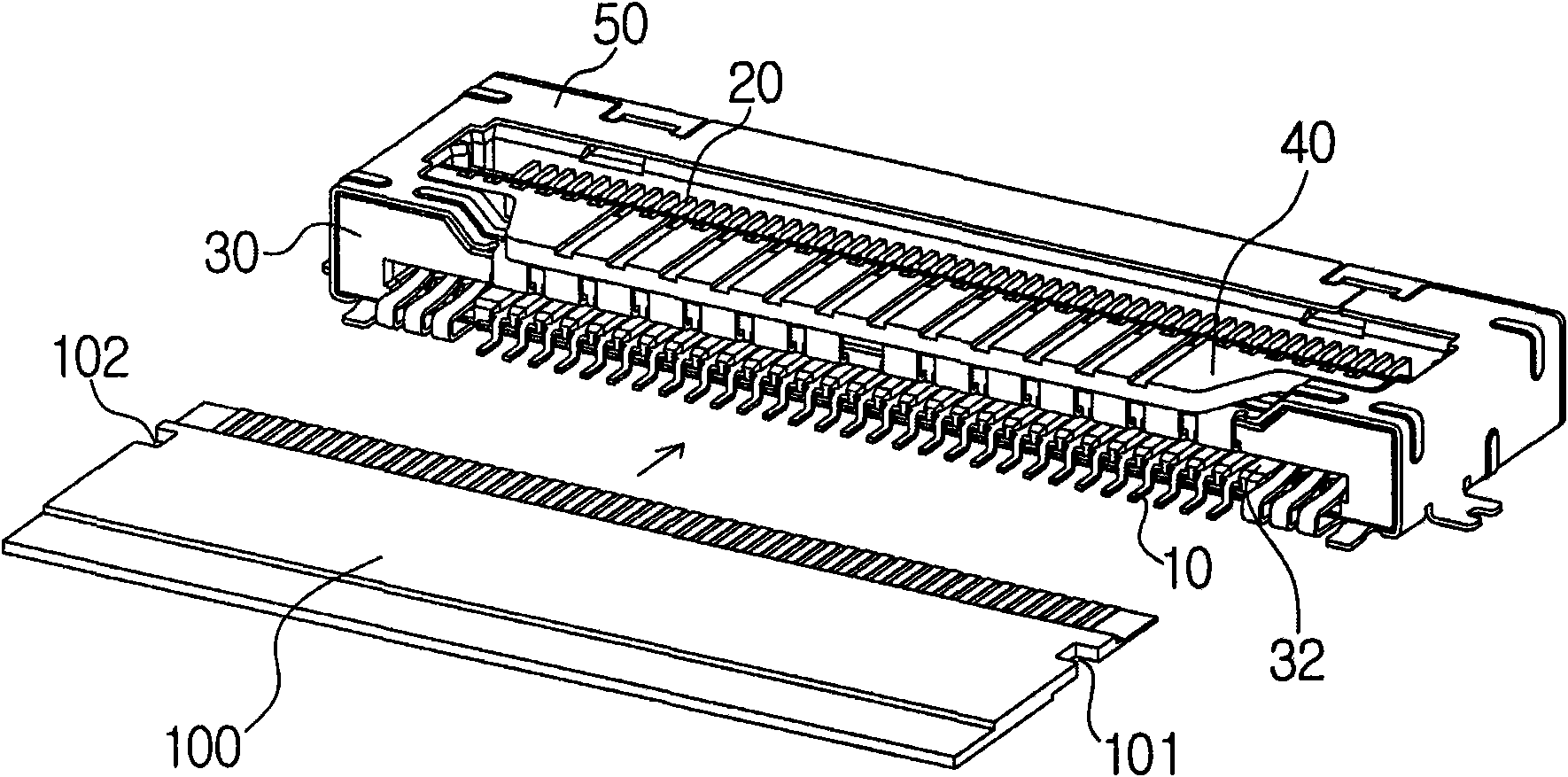

[0027] figure 2 It is a perspective view of the joint according to the present invention.

[0028] The connector of the present invention includes: a shell 30 formed with an FPC / FFC100 socket 32; the first terminal group 10 inserted / set onto the shell 30 from the direction of the socket 32 of the FPC / FFC and inserted / set onto the shell 30 from the reverse direction of the socket The second terminal group 20; the brake 40 that rotates under the support of the terminals of the second terminal group 20; the outer cover 50 that wraps the shell.

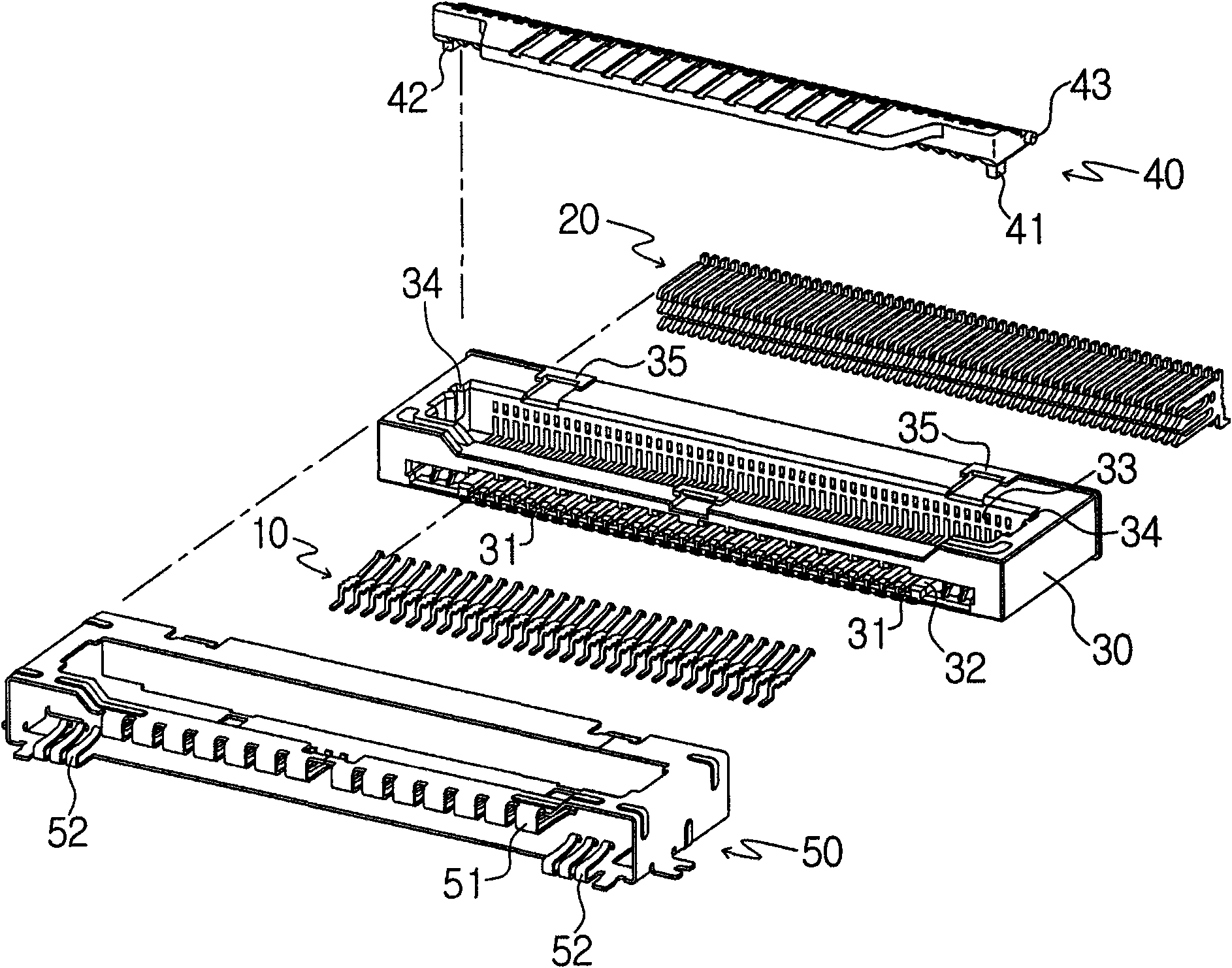

[0029] image 3 It is a schematic diagram of the disassembled state of the joint of the present invention. After the shell 30 is provided, the first terminal of the first terminal group 10 is inserted into the shell 30 from the socket direction through the first terminal socket 31 formed on the socket 32 si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com