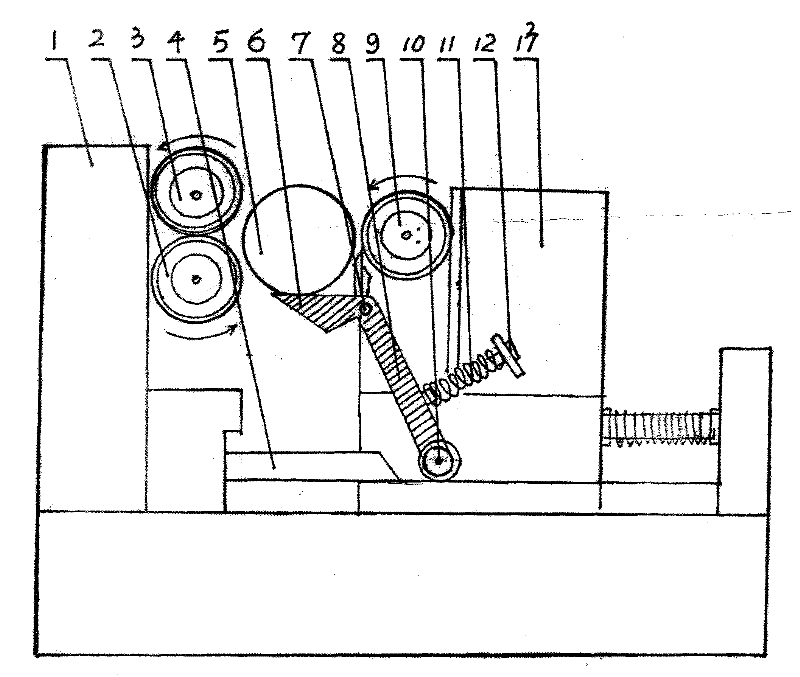

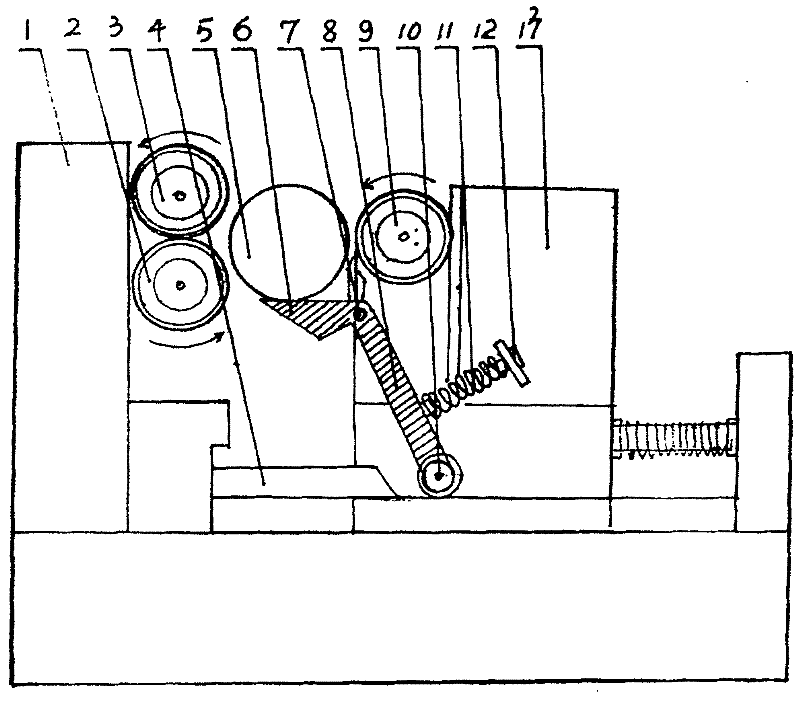

Device capable of automatically adjusting log peeling position of log-core veneer lathe

An automatic adjustment and rotary cutting machine technology, which is applied in the manufacture of thin wood chips, wood processing equipment, manufacturing tools, etc., can solve the problem that the production efficiency of non-card shaft rotary cutting machines cannot meet the design requirements, and the effective time of rotary cutting cannot meet the requirements. Design time and other issues, achieve obvious economic and social benefits, improve rotary cutting efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Since the backwood hook of the existing non-card shaft rotary cutting machine is designed on the basis of large-diameter log rotary cutting, and is fixedly installed on the movable knife holder, it determines that all domestic non-card shaft rotary cutting machines are used in rotary cutting. Large-diameter logs are easy to use, but continuous automatic production cannot be realized when rotary-cutting small-diameter logs; and production enterprises, especially small and medium-sized enterprises, cannot only rotary-cut large-diameter logs and not small-diameter logs. . Therefore, designing a non-clamping shaft rotary cutting machine that can automatically adjust the position of the log rotary cutting, which can successfully complete the automatic production of large-diameter log rotary cutting and small-diameter log rotary cutting, is an improvement for plywood processing enterprises at present. The best choice for productivity.

[0013] After years of research, the ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com