Synchronous grouting simulation test platform of shield tunneling machine

A simulation test and synchronous grouting technology, which is applied in the direction of shaft lining, tunnel lining, underground chamber, etc., can solve the problem that the grouting simulation device cannot perform the simultaneous grouting simulation test of the shield tunneling machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

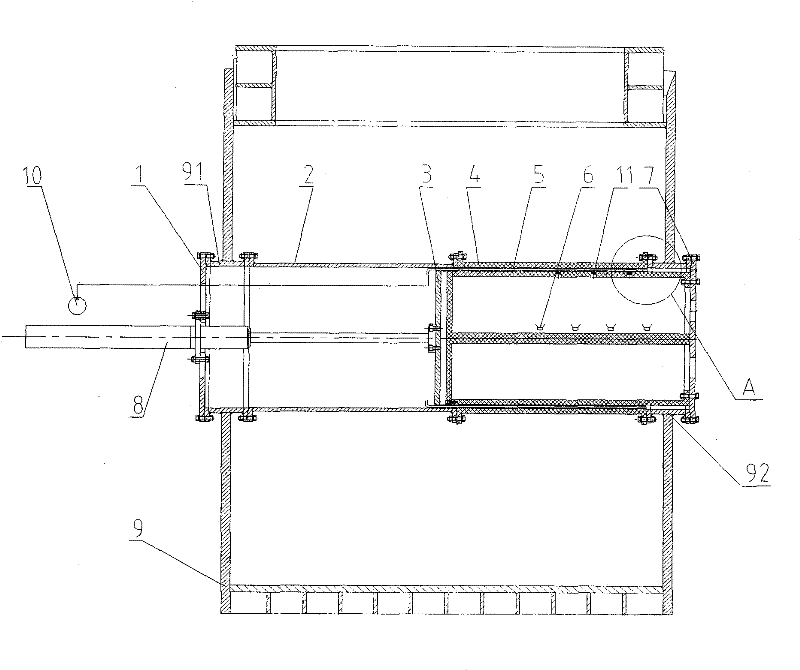

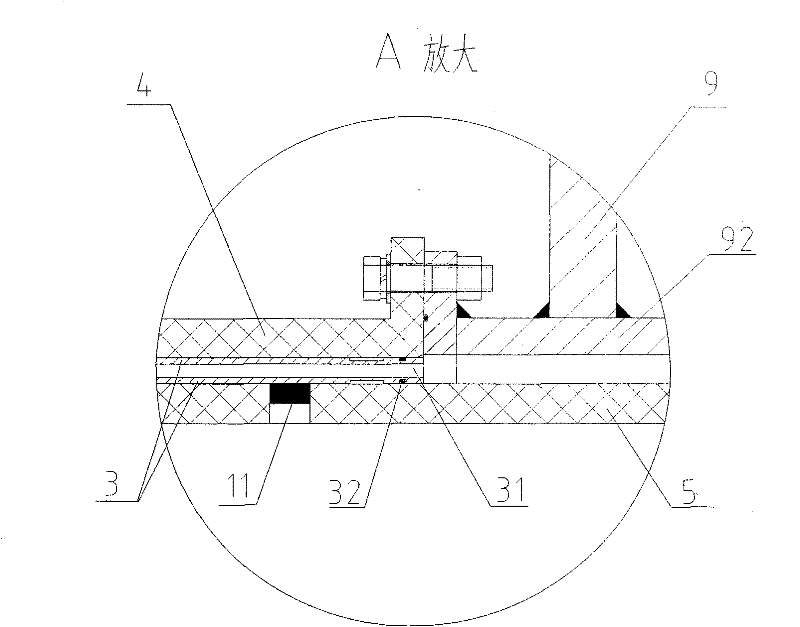

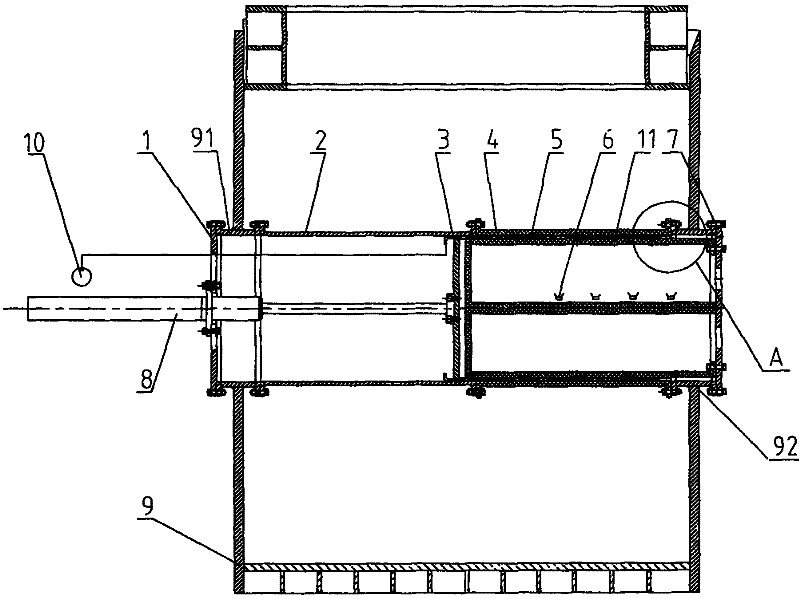

[0021] see figure 1 Schematic diagram of the structure of the present invention, the shield tunneling machine synchronous grouting simulation test platform includes soil box 9, left connecting pipe 91, right connecting pipe 92, left end cover 1, right end cover 7, simulated segment 5, simulated shield tail 3 , Propel hydraulic cylinder 8, guide barrel 2, transparent outer barrel 4, earth pressure sensor 11, camera 6 and grouting pump 10.

[0022] The soil box 9 is a square box structure made of steel, which is placed above the ground. The size of the soil box 9 is 2.5m in length, 2.5m in width, and 3m in depth, and can be filled with test soil inside. The left connecting pipe 91 and the right connecting pipe 92 are short tubular members made of steel, and the left connecting pipe 91 and the right connecting pipe 92 are coaxially welded a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com