Calibration pattern of camera and calibration and detection method based on same

A camera calibration and detection method technology, applied in the field of camera vision, can solve problems such as large amount of computation, affecting detection accuracy, and weak anti-noise performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the technical features of the present invention more comprehensible, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

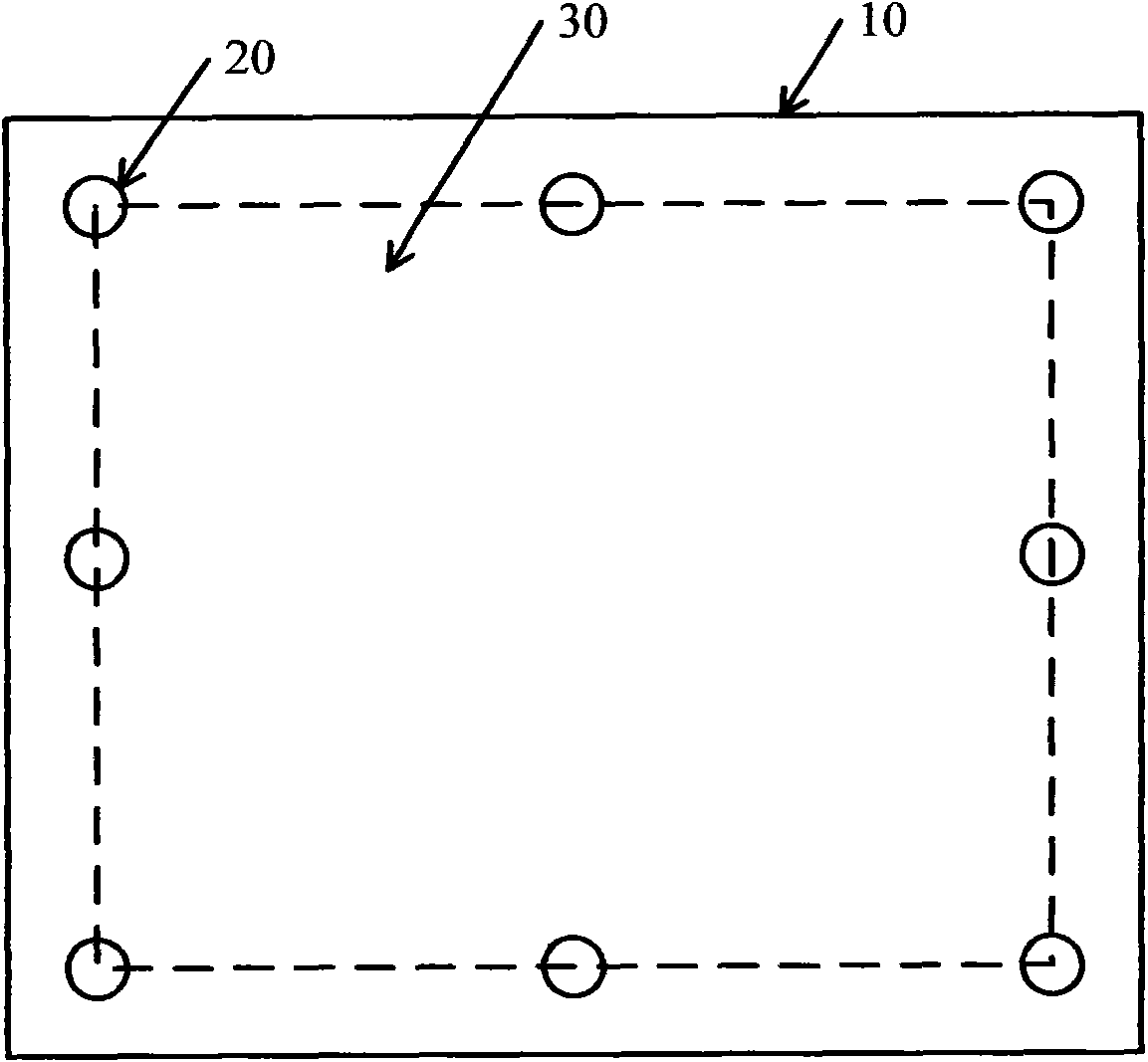

[0051] Please refer to image 3 , which is a top view of the camera calibration target provided by an embodiment of the present invention. As shown in the figure, the surface of the calibration target 10 has eight calibration circles 20, forming a rectangular area 30 on the surface of the calibration target 10, and the surface of the calibration target 10 Spend calibration circle 20 degrees vary. For example, the surface of the calibration target is black, and the calibration circle is white, so their There is a large difference in the degree value, which is suitable for calibration circle The background is separated. In a preferred embodiment, a black tablecloth printed with 8 white calibration circles can be selected as the calibration target. In this w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com