Composite material pole tower outside vertical grounding led-down method and pole tower thereof

A technology of composite materials and grounding down conductors, applied in the configuration of grounding wires, towers, building types, etc., can solve the problems affecting the lightning protection effect of composite towers, the compression of the width of transmission corridors affecting lines, and antifouling, etc., to achieve Easy to implement, simple structure, and reduced lightning tripping rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

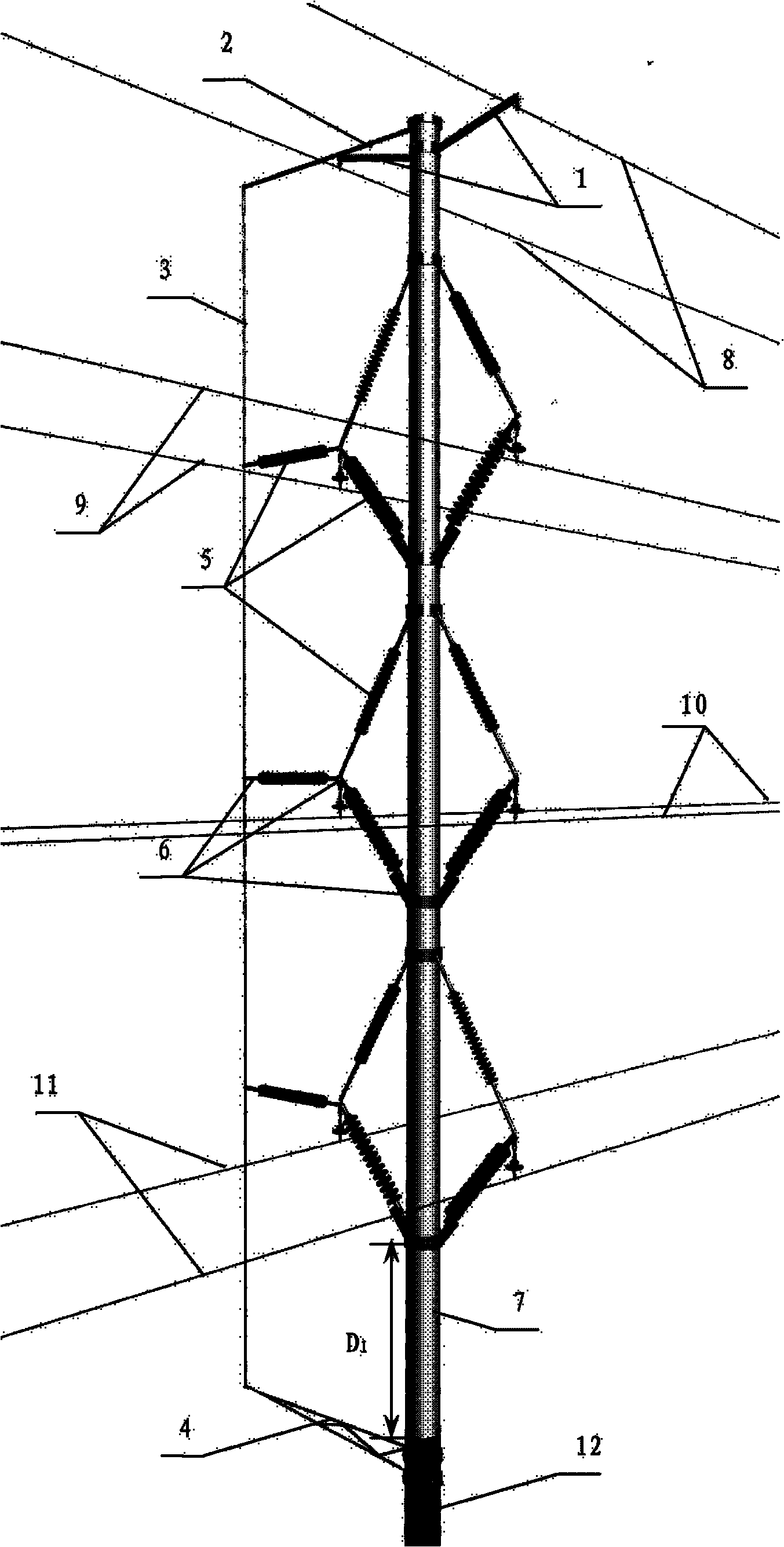

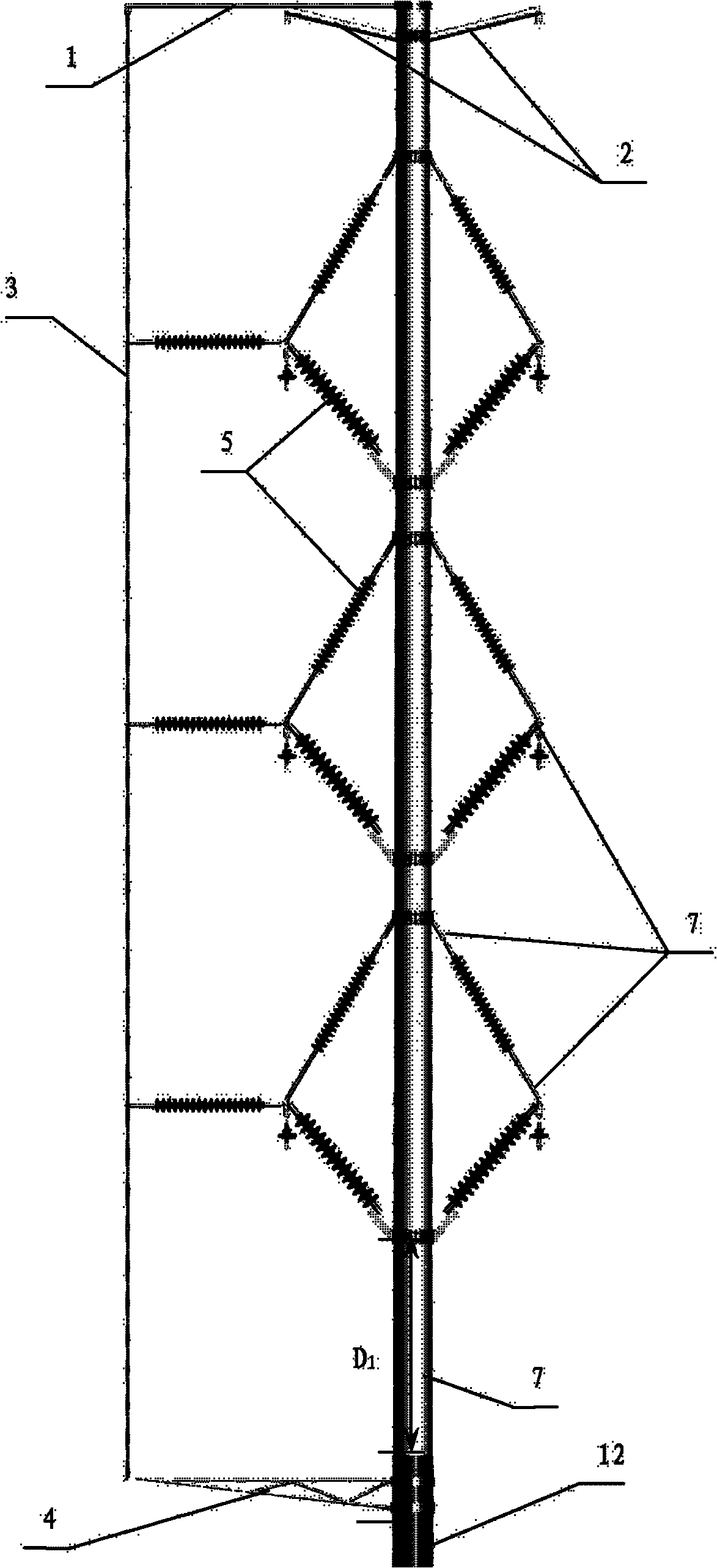

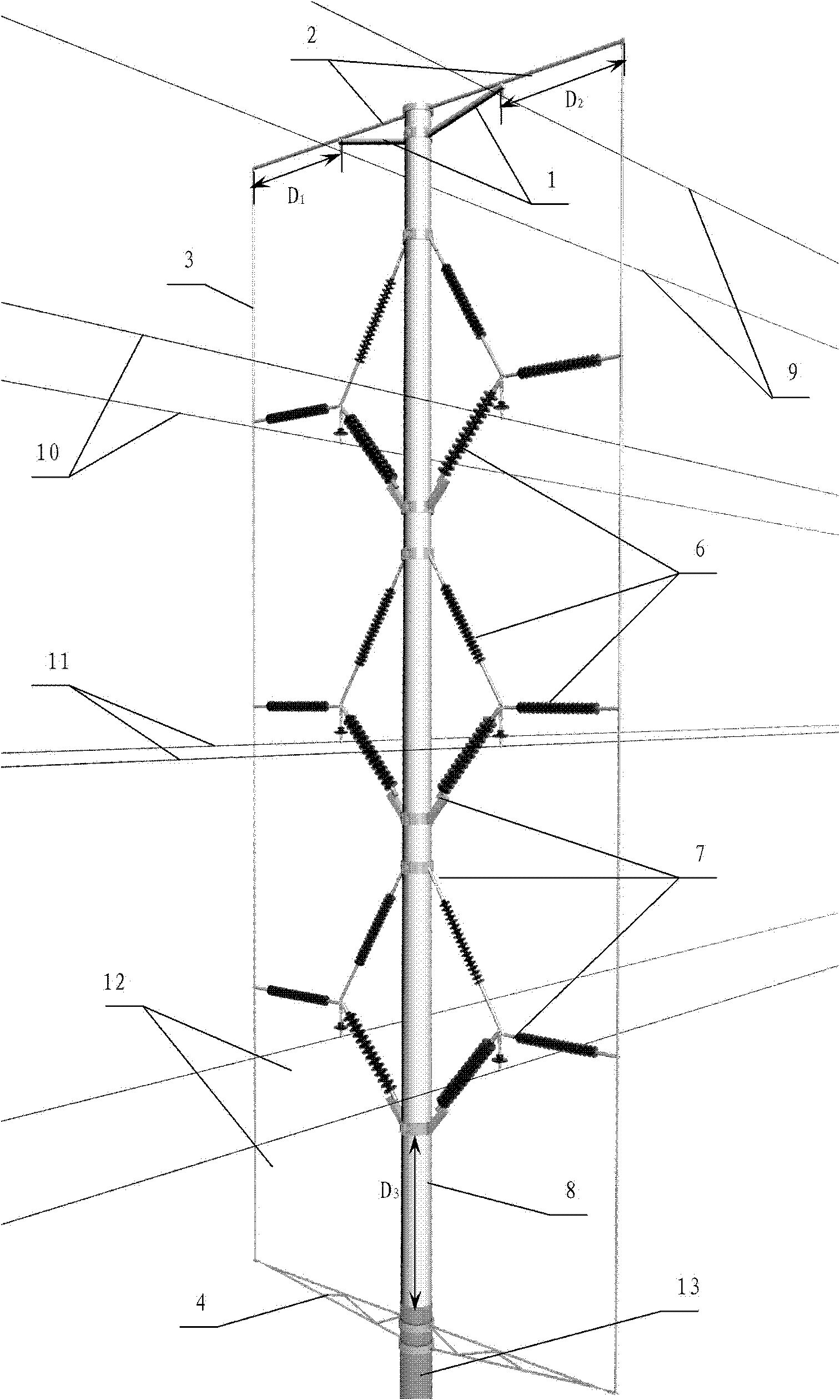

[0025] figure 1 , Mark description in 3: 1-ground crossarm, 2-metal crossarm on grounding downlead, 3-grounding downconductor, 4-metal crossarm under grounding downconductor, 5-composite insulator, 6-crossarm Bearing fittings, 7-the tower body part of the tower head, 8-ground wire, 9-near side wire, 10-far side wire, 11-lower phase wire, 12-the lower part of the tower body, 13-the lower part of the tower body.

[0026] In the present invention, a section of metal cross-arm 2 on the grounding down-conductor is erected on the extension line of a certain side of the grounding cross-arm 1, and the end of the metal cross-arm 2 vertically leads down the grounding down-conductor 3, and the grounding down-conductor 3 The minimum air gap distance from the proximal conductor is D 1 (D 1 The value is determined by the lightning protection calculation)), the grounding downconductor 3 is connected to the tower through the corresponding grounding downconductor lower metal cross arm 4 at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com