Method for vertical grounding led-down outside composite material pole tower and pole tower thereof

A composite material and grounding down-conductor technology, which is applied in the configuration of grounding wires, the spatial arrangement/configuration of cables, etc., can solve the problems of the transmission corridor width compression and anti-fouling that affect the line, and the lightning protection effect of composite material towers. , to achieve the effect of easy implementation, simple structure, and reduced lightning trip rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

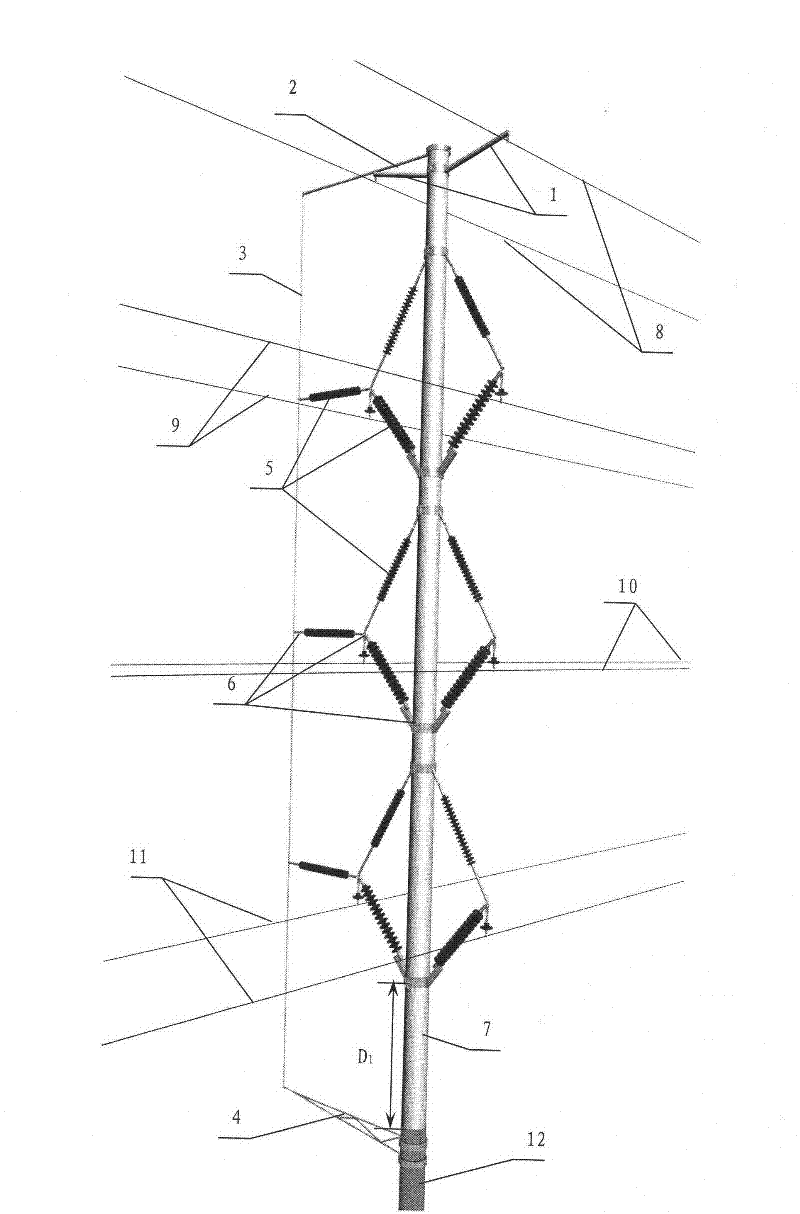

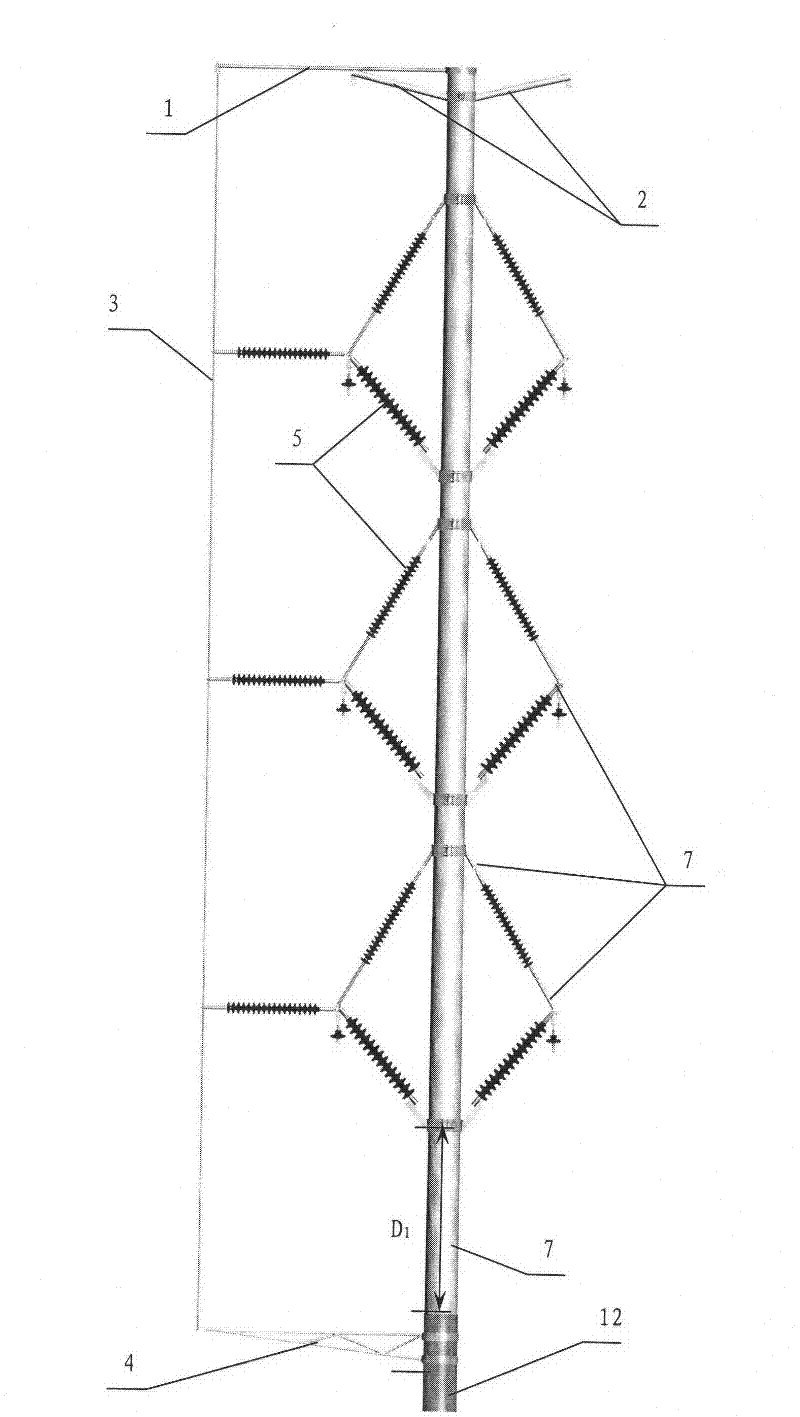

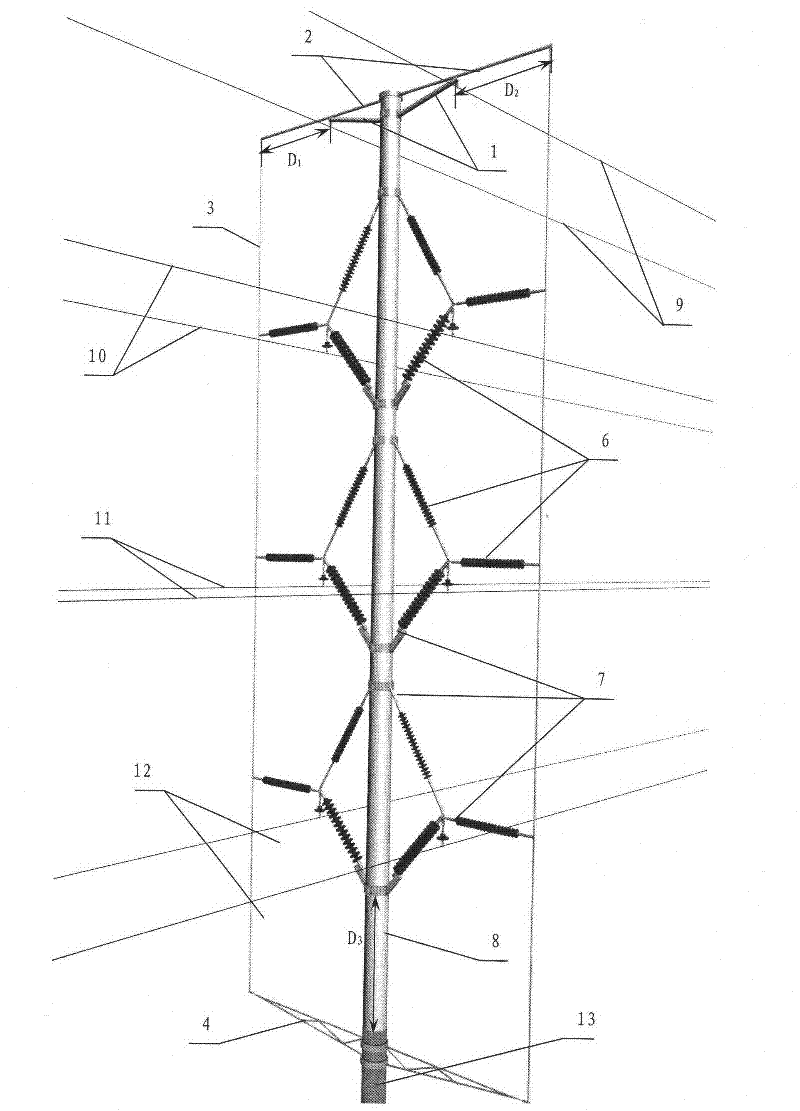

[0025] figure 1 , Mark description in 3: 1-ground crossarm, 2-metal crossarm on grounding downlead, 3-grounding downconductor, 4-metal crossarm under grounding downconductor, 5-composite insulator, 6-crossarm Bearing fittings, 7-the tower body part of the tower head, 8-ground wire, 9-near side wire, 10-far side wire, 11-lower phase wire, 12-the lower part of the tower body, 13-the lower part of the tower body.

[0026] In the present invention, a section of metal cross-arm 2 on the grounding down-conductor is erected on the extension line of a certain side of the grounding cross-arm 1, and the end of the metal cross-arm 2 vertically leads down the grounding down-conductor 3, and the grounding down-conductor 3 The minimum air gap distance from the proximal conductor is D 1 (D 1 The value is determined by the lightning protection calculation)), the grounding downconductor 3 is connected to the tower through the corresponding grounding downconductor lower metal cross arm 4 at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com