Steel plate welding aligning and adjusting mechanism

A positive adjustment, steel plate technology, applied in the field of steel plate welding alignment adjustment mechanism, to achieve the effects of quick adjustment and alignment, improved production efficiency, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

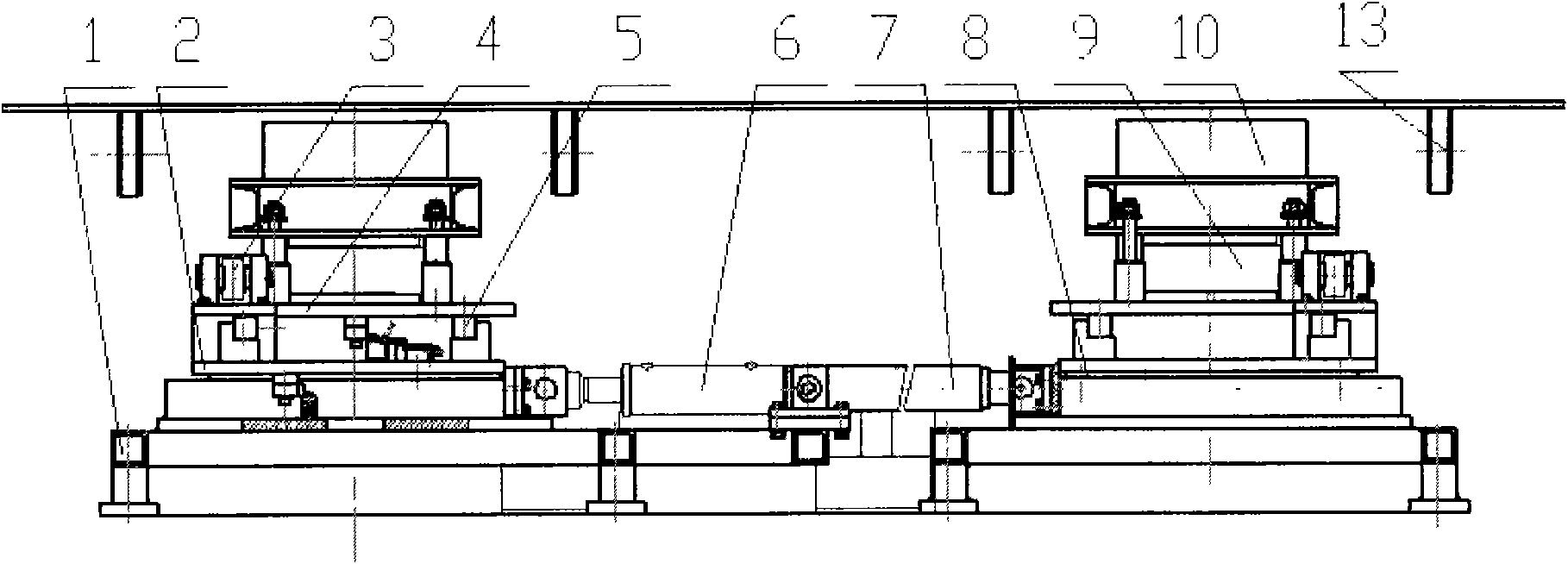

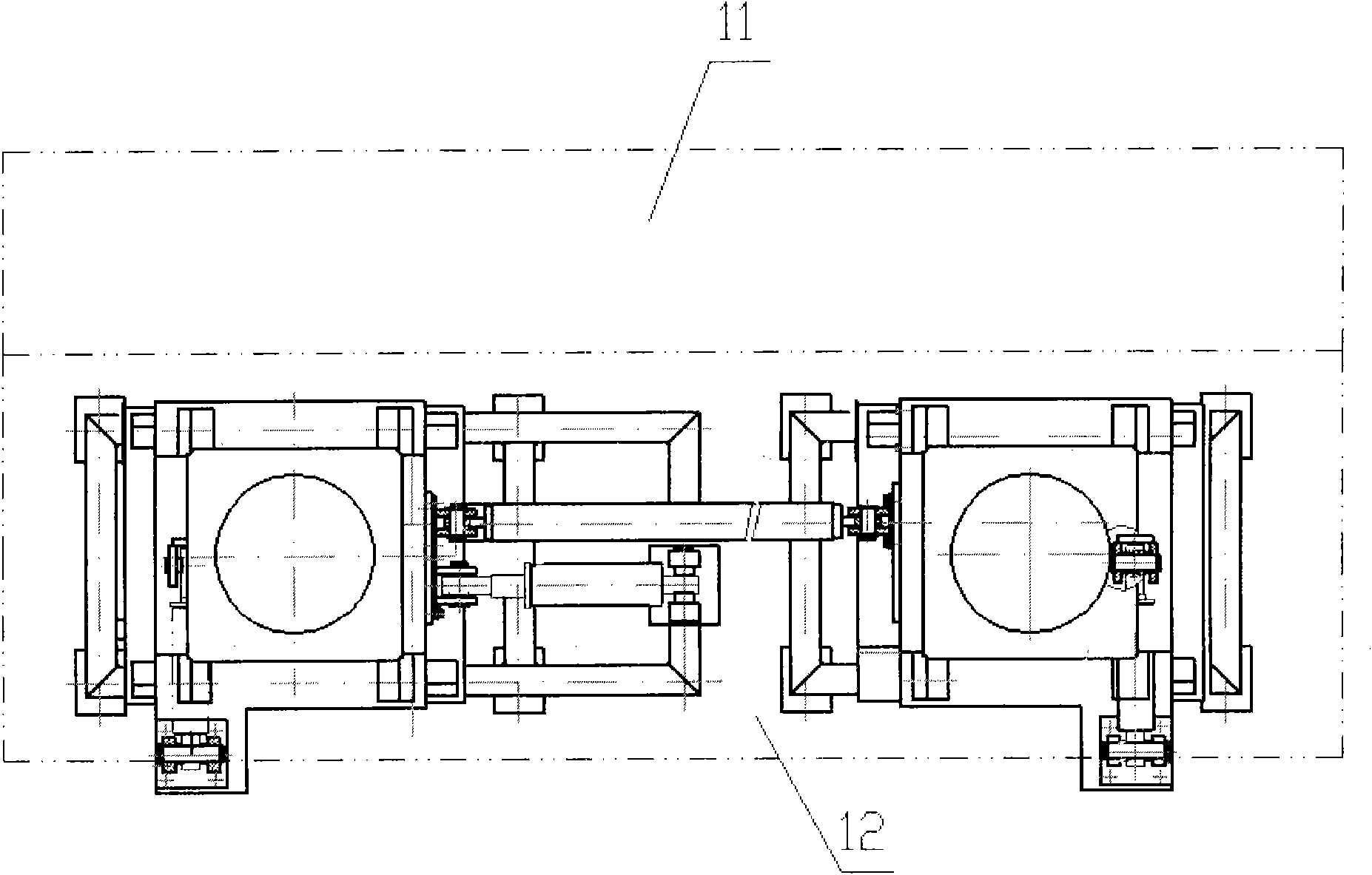

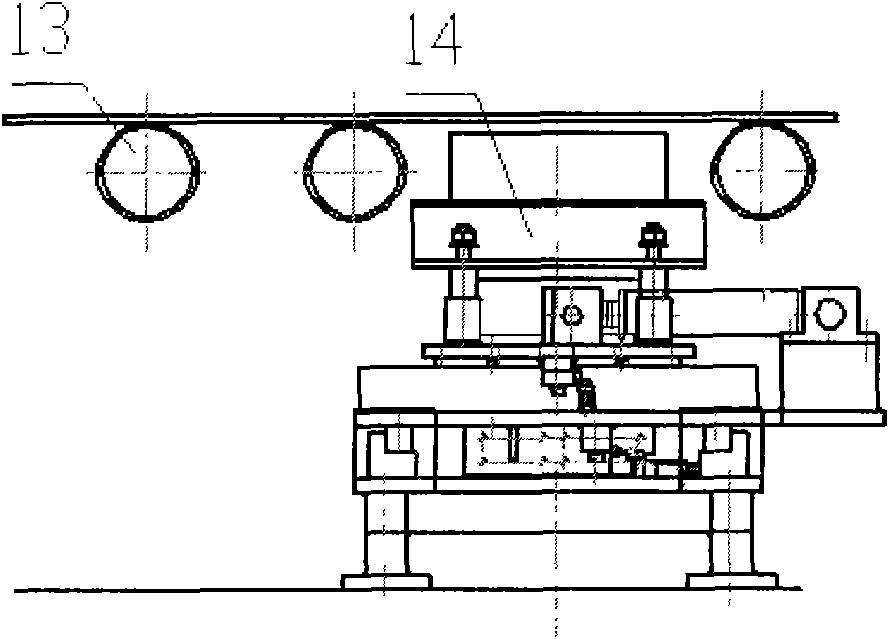

[0017] Such as figure 1 , 2 , 3, when the conveying mechanism on the production line transports the previous steel plate 11 to the welding position along the support roller above the steel plate welding alignment adjustment mechanism and positions it, it starts to transport the rear steel plate 12, when the latter steel plate 12 and After the previous steel plate 11 contacts, the air bag 9 jacks up the electromagnetic chuck fixing frame 14, the electromagnetic chuck 10 and the steel plate 12 are sucked together, the longitudinal hydraulic cylinder 3 is started, and the longitudinal sliding seat 5 is pushed to move on the longitudinal slide rail 4, and the steel plate 12 moves along with it. Longitudinal movement until the side facades of the front and rear two steel plates 11 and 12 are attached together; then the horizontal hydraulic cylinder 6 is activated to push the horizontal sliding seat 8 to move on the horizontal slide rail 2, and the steel plate 12 moves along the hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com