Modular microfluidic chip clamp based on magnetic link

A microfluidic chip, modular technology, applied in the direction of laboratory equipment, laboratory containers, chemical instruments and methods, etc., can solve the problem of the inability to realize the integration and fixation of multiple chips, poor versatility, and the inability to meet the requirements of liquid flow through the chip. Requirements and other issues, to achieve the effect of building and adjustment, simple structure, easy disassembly and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below through specific embodiments and accompanying drawings.

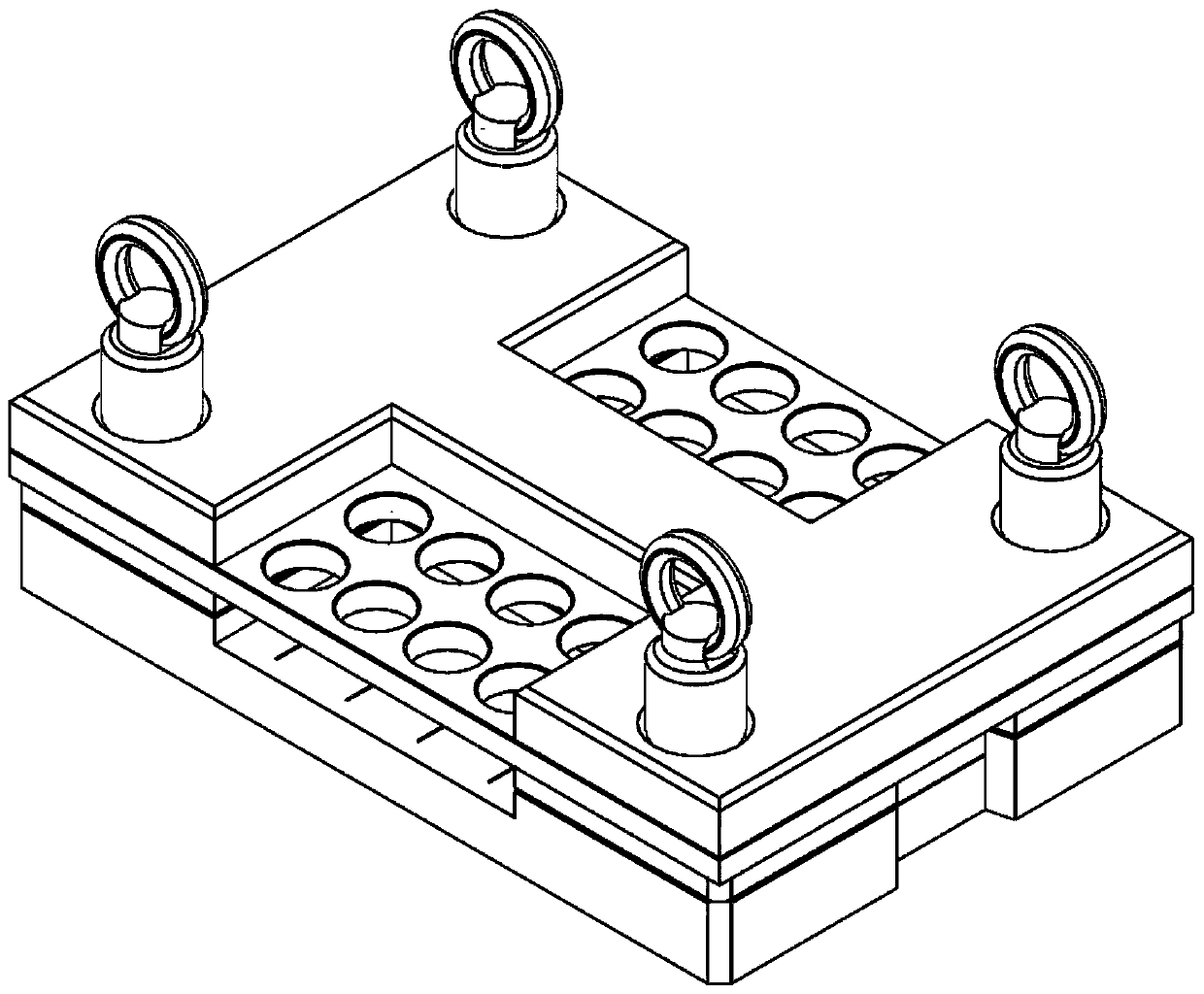

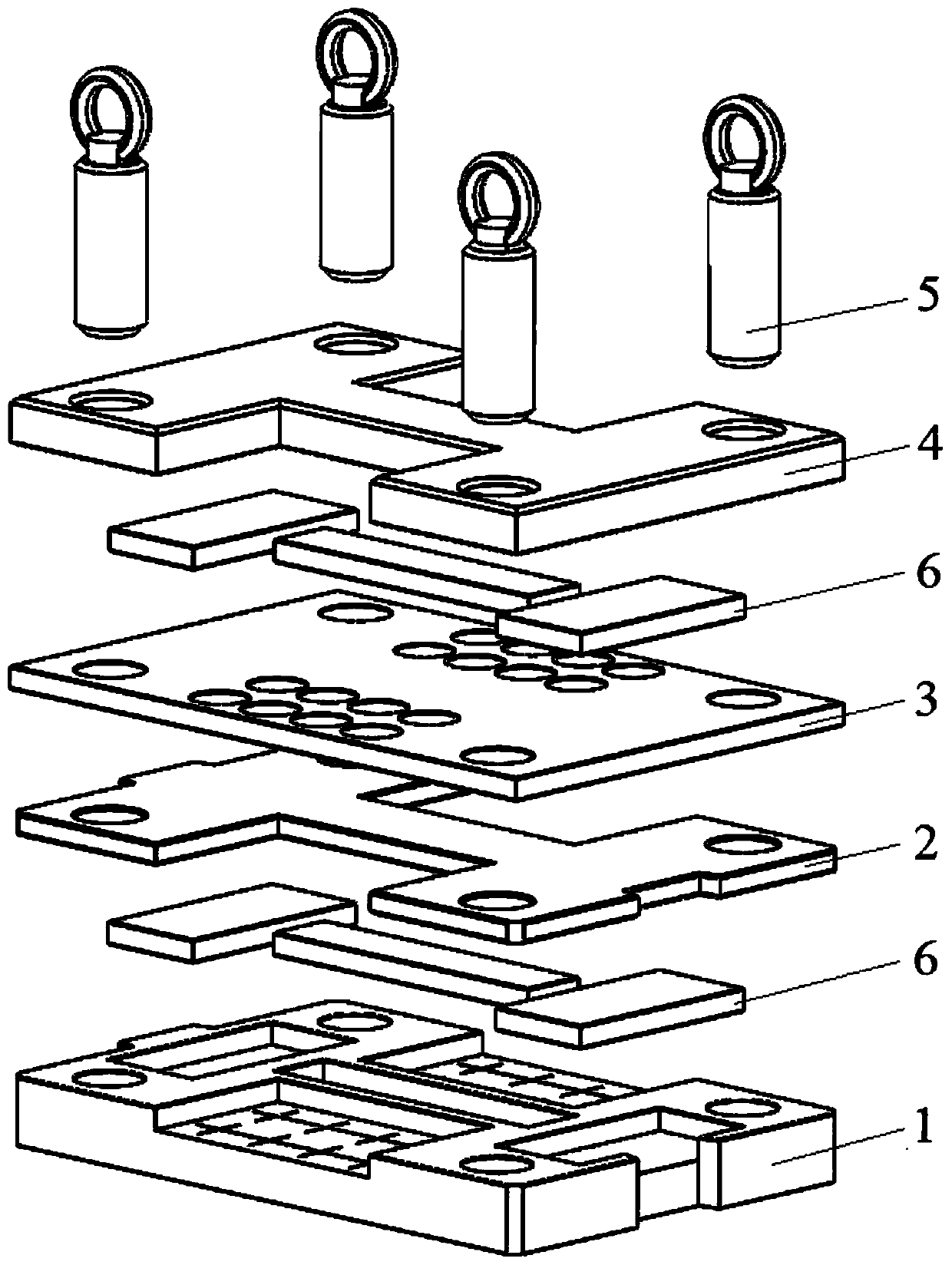

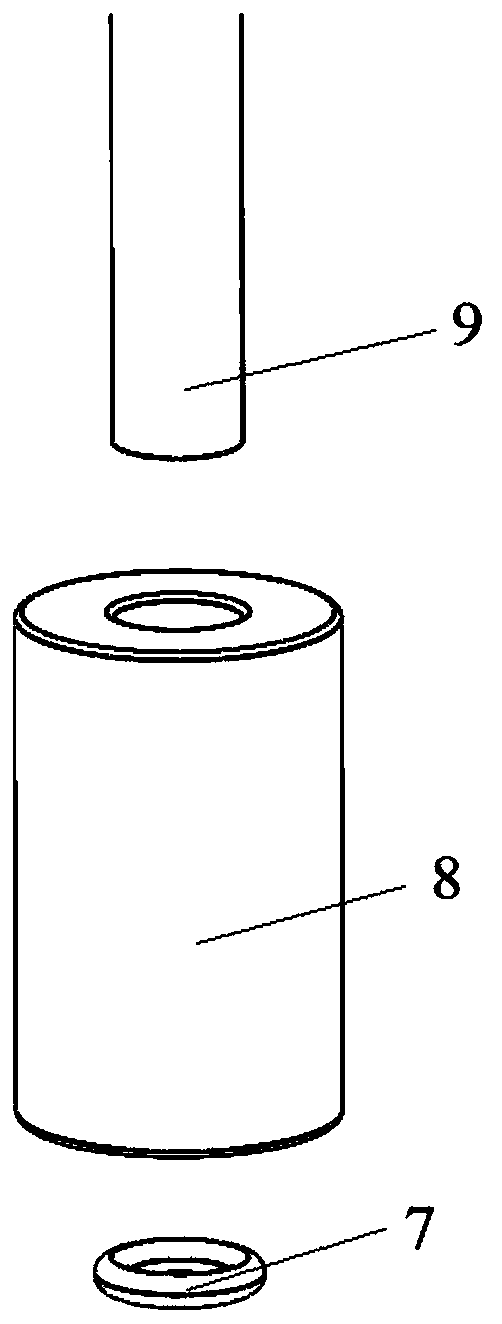

[0027] This embodiment provides a modular microfluidic chip fixture that is simple in structure, easy to adjust, and easy to use. figure 1 It is an assembly drawing of the fixture as a whole. like figure 1 As shown, the fixture includes a base plate 1, an adjustment plate 2, a positioning module 3, a cover plate 4, a circular guide post 5, a rectangular permanent magnet material 6, an O-ring 7, a cylindrical permanent magnet joint 8, and a liquid inlet conduit 9 . 10 in the figure is a microfluidic chip.

[0028] A rectangular permanent magnet material 6 is embedded in the bottom plate 1, and the connection of each part of the fixture is realized by magnetic force; two symmetrical rectangular grooves are processed on the bottom plate 1, the length is 25.4mm, which is the same as the width of a standard slide glass, and the width is 10-30mm , used for inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com