Method for synthesizing elemental selenium nano-belt

A synthesis method and elemental selenium technology, applied in the field of nanomaterials, can solve the problems of using surfactants, complex processes, and high equipment requirements, and achieve the effects of convenient operation, simple process route, and large aspect ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The invention discloses a method for synthesizing elemental selenium nanobelts, which uses sodium selenite as a selenium source and β-cyclodextrin as a reducing agent to prepare elemental selenium nanobelts in one step through hydrothermal reaction in an aqueous solution system. Specific steps are as follows:

[0015] The first step: dissolving commercially available sodium selenite and β-cyclodextrin with a molar ratio of 1:0.5 to 1:5 in distilled water to form a colorless and transparent solution; Add distilled water to 50-80% of the total volume in an ethylene-lined stainless steel reaction kettle, seal and tighten.

[0016] Step 2: Put the reaction kettle into a constant temperature oven, set the reaction temperature to 140-180°C, and the reaction time to 6-18 hours.

[0017] The third step: centrifuging the product obtained in the second step, and washing with distilled water and absolute ethanol for 3 to 5 times respectively. Finally, vacuum dry in a vacuum oven...

Embodiment 1

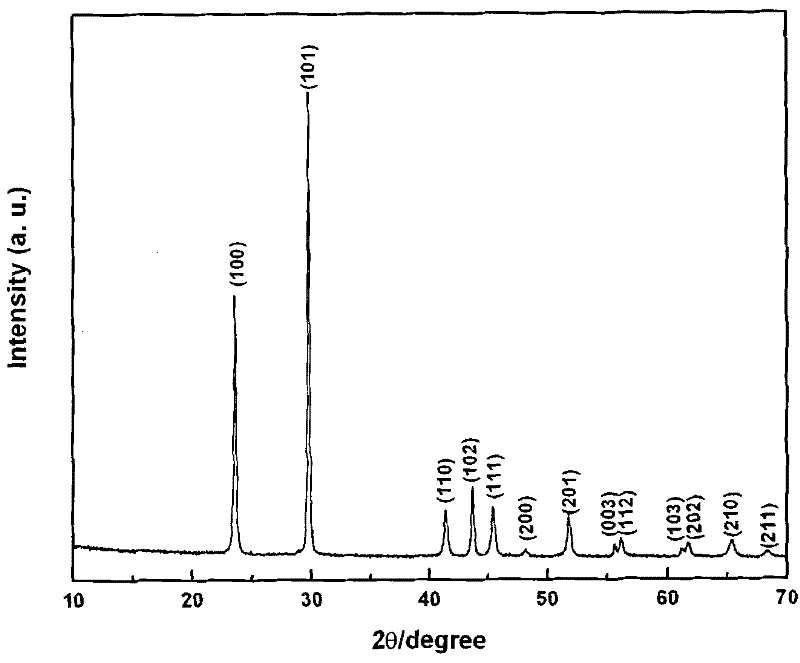

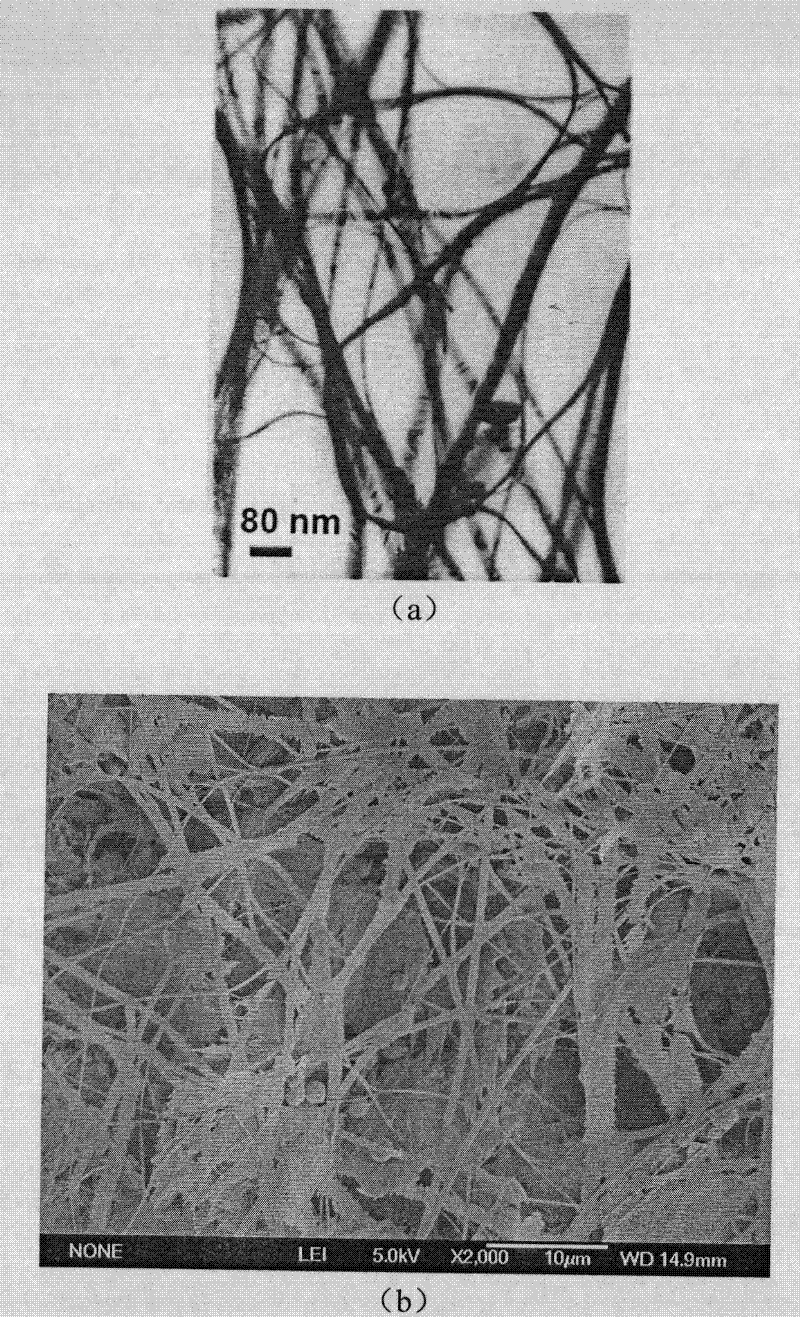

[0020] Prepare a mixed solution of sodium selenite and β-cyclodextrin with a molar ratio of 1:2, weigh 0.005mol of analytically pure sodium selenite and 0.01mol of β-cyclodextrin and dissolve them in distilled water, and transfer the resulting clear solution to a polymer In a stainless steel autoclave lined with tetrafluoroethylene, add distilled water to 80% of the total volume. After fully stirring, tighten the autoclave and put it into a constant temperature oven at 160°C for 12 hours. After the reaction was over, the reactor was taken out and allowed to cool naturally. Subsequently, the precipitate in the kettle was filtered, washed three times with distilled water, and then washed twice with absolute ethanol. Finally, the sample was dried in a vacuum oven at 60° C. for 4 hours to obtain elemental selenium nanobelts. figure 1 For the X-ray diffraction spectrum of the elemental selenium nanobelt prepared in this embodiment, all diffraction peaks in the figure can be index...

Embodiment 2

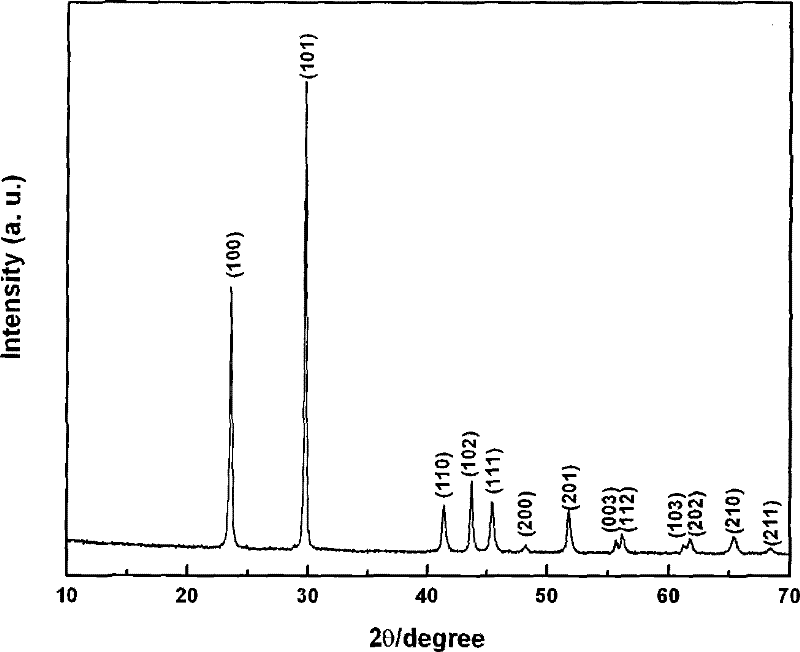

[0022] Prepare sodium selenite and β-cyclodextrin with a molar ratio of 1:0.5 and dissolve them in distilled water, transfer the resulting clear solution to a polytetrafluoroethylene-lined stainless steel autoclave, and add distilled water to 80% of the total volume. After fully stirring, tighten the autoclave and put it in a constant temperature oven at 140°C for 18 hours. After the reaction was over, the reactor was taken out and allowed to cool naturally. Subsequently, the precipitate in the kettle was filtered, washed three times with distilled water, and then washed twice with absolute ethanol. Finally, the sample was dried in a vacuum oven at 50° C. for 6 hours to obtain elemental selenium nanobelts. Elemental selenium has a nanometer bandwidth of 60-80nm, a thickness of 10-20nm, and a length of more than tens of microns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com