Slip-limiting differential mechanism with noncircular bevel gear

A non-conical gear and limited-slip differential technology, which is applied in the direction of differential transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of small variation range of transmission ratio, easy pulsation and impact, small variation range, etc. problems, to achieve the effect of increasing the range of numerical changes, increasing the locking coefficient, and reducing pulsation and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

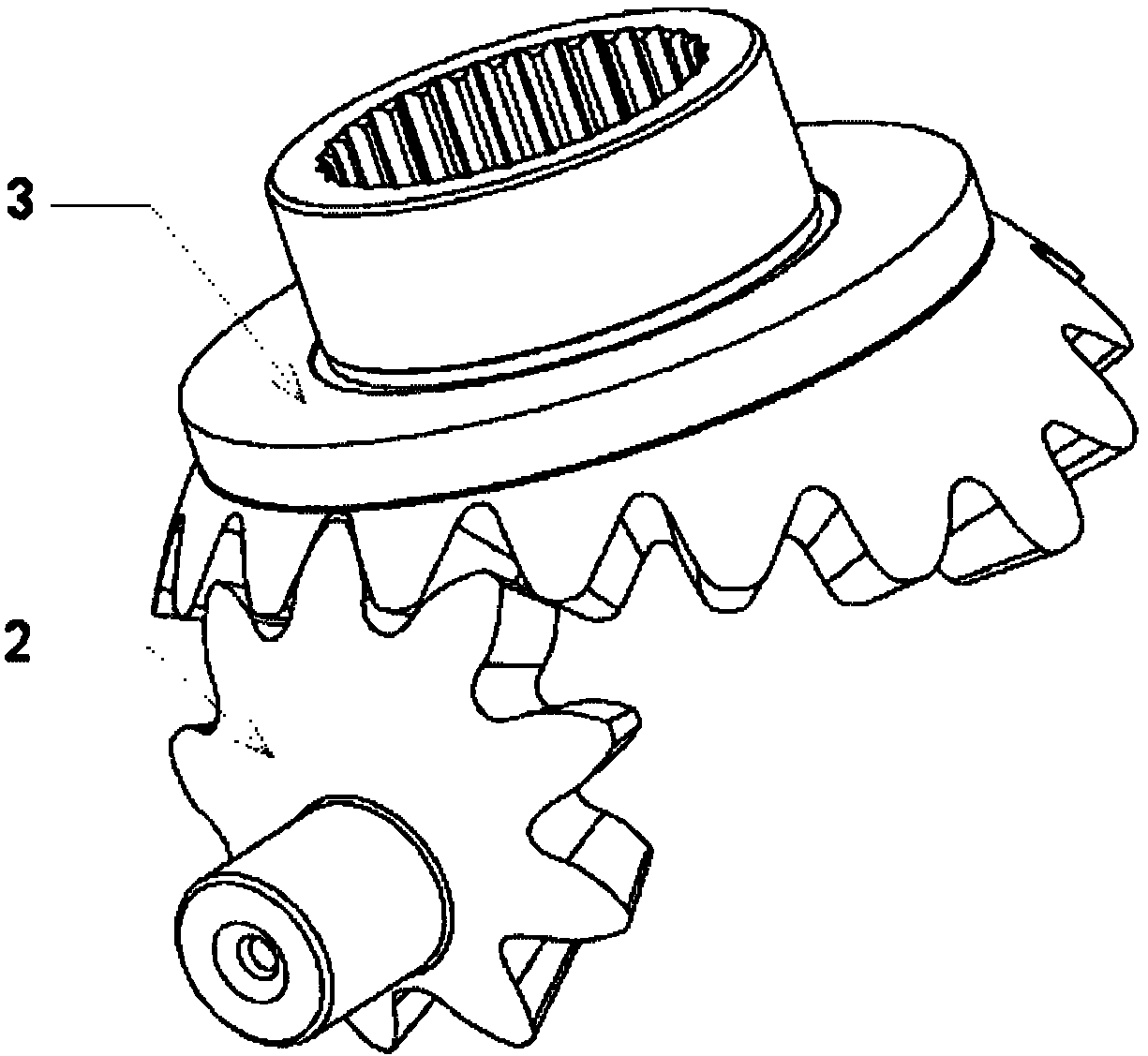

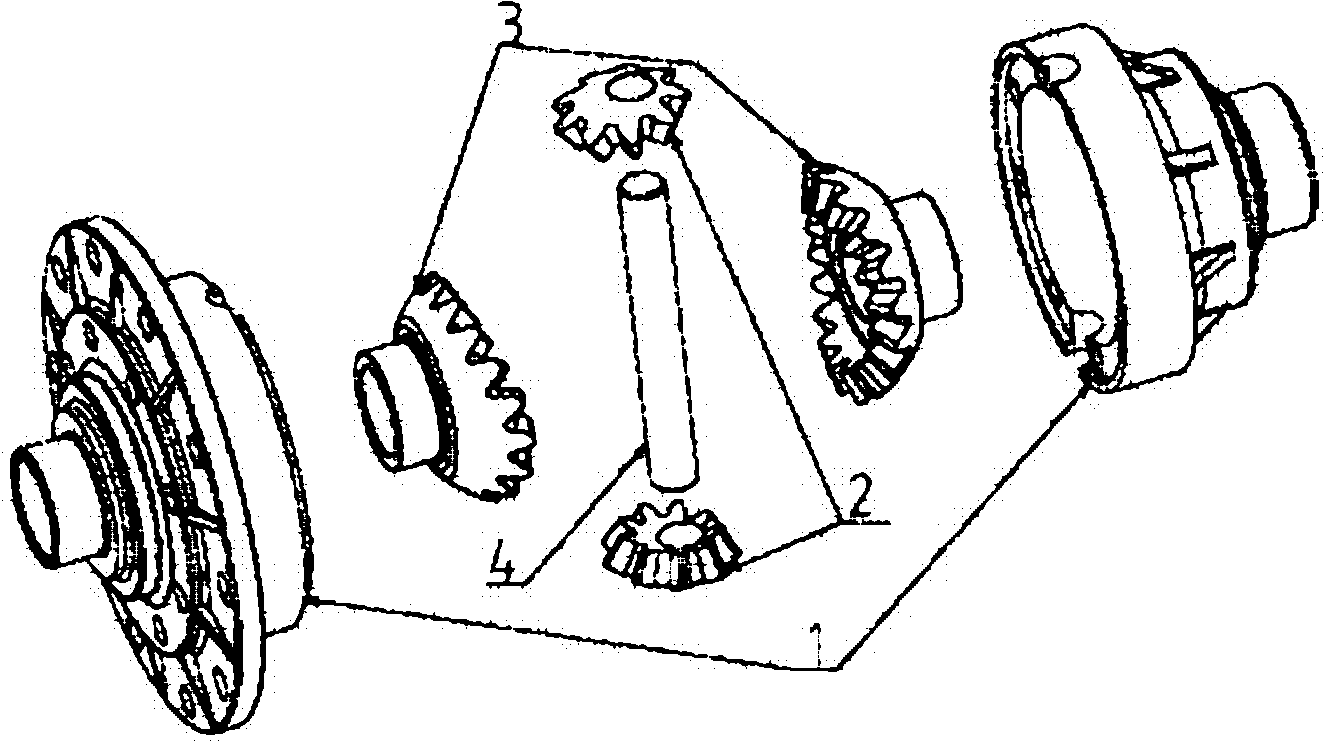

[0019] Embodiment: The non-circular planetary gear and non-circular half-shaft gear transmission ratio rule is as follows set, where: i 32 is the transmission ratio between the side gear and the planetary gear, z 2 ,z 3 are the number of teeth of the planetary gear and the half-shaft gear, respectively, is the planetary gear rotation angle, c=0~0.5 is a constant. Such as figure 2 As shown, the non-circular planetary gear 2 meshes with the non-circular side shaft gear 3, and the former is connected with the housing 1 through the shaft and driven by the housing. Among them, z 2 =9, zx=18, c=0.4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com