Differential mechanism with variable transmission ratio and eliminating slip

A limited-slip differential and variable transmission ratio technology, applied in transmissions, gear transmissions, differential transmissions, etc., can solve problems such as uneven running, rapid tire wear, and large steering resistance, and achieve enhanced off-road capacity, improve the locking coefficient, prevent the effect of early wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with accompanying drawing:

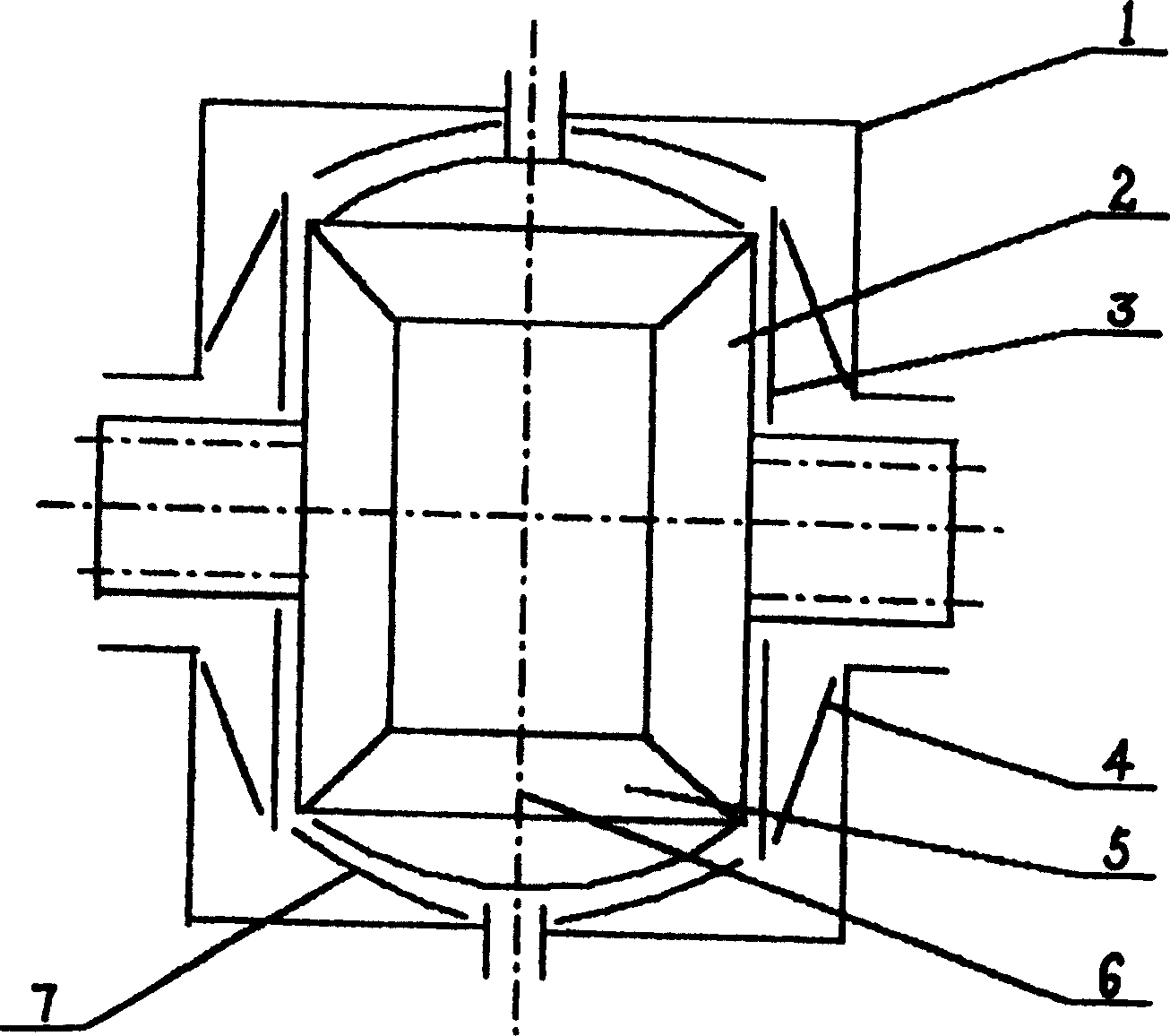

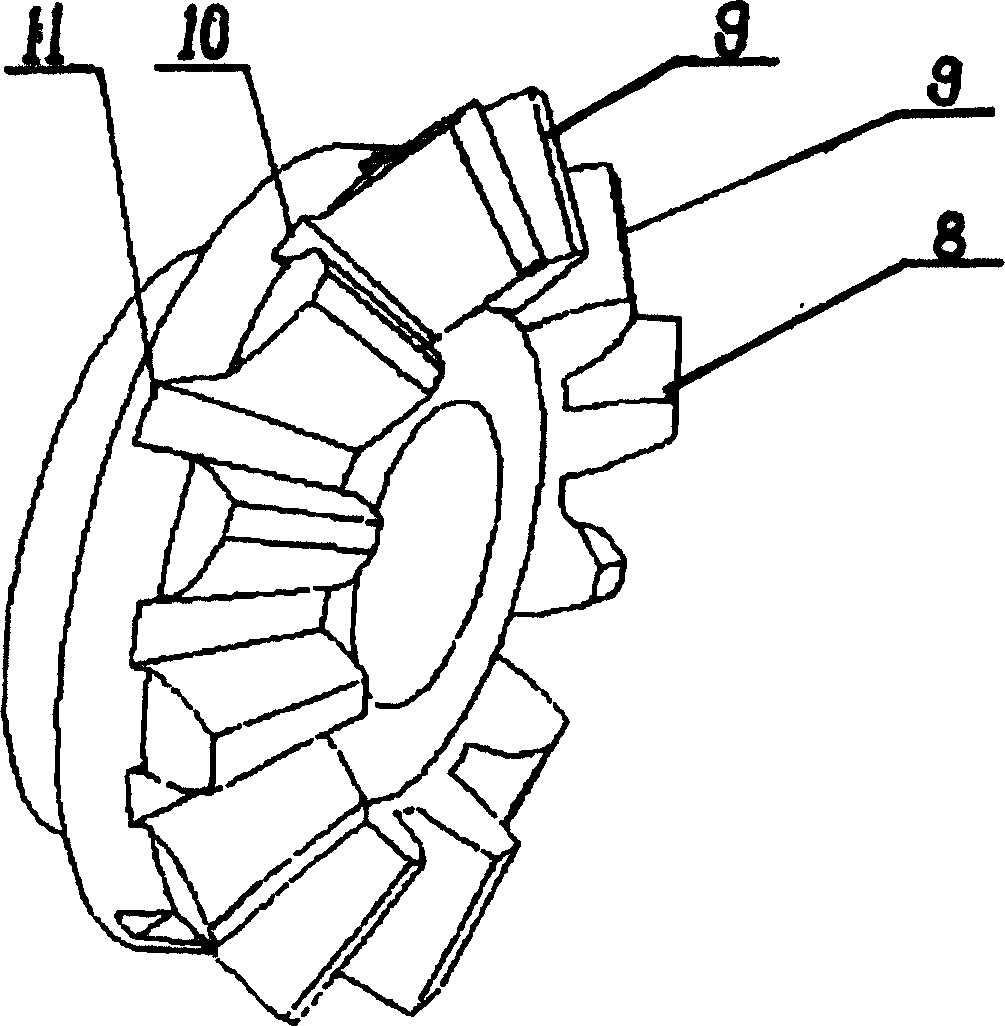

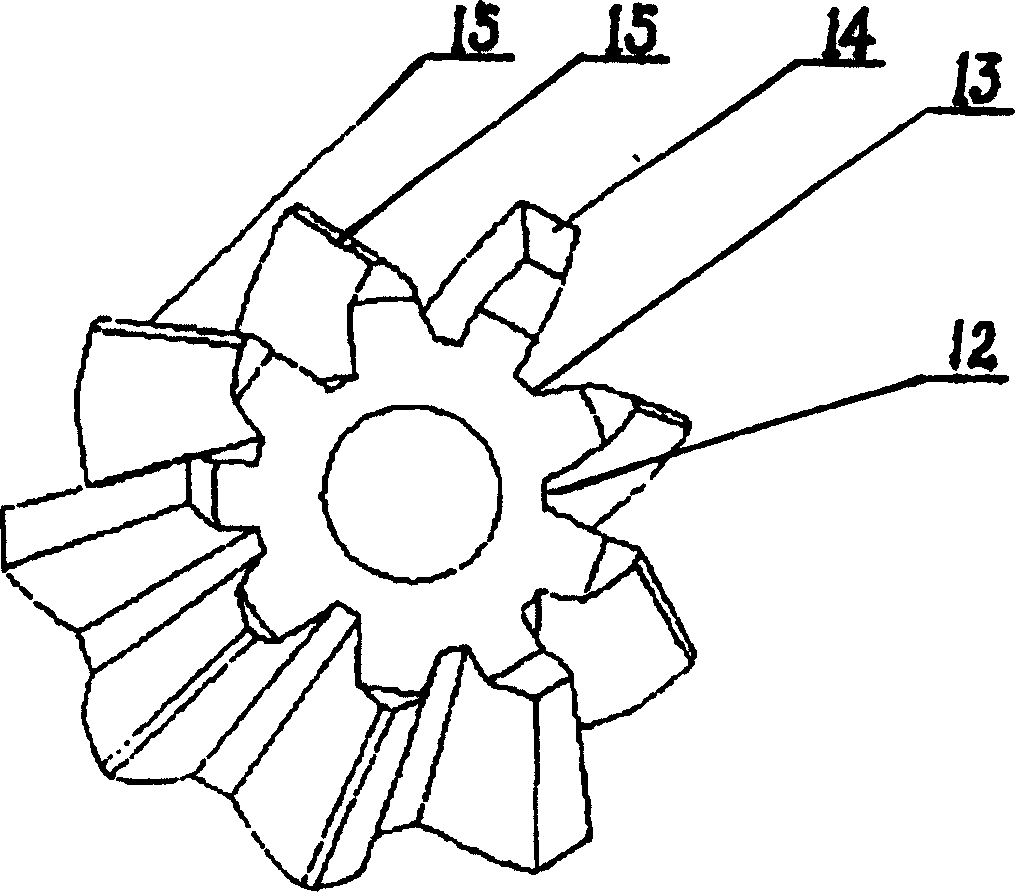

[0019] A variable transmission ratio limited-slip differential, comprising a differential case 1, a planetary gear 5 and a side gear 2 arranged on a cross shaft 6 inside the differential case 1, and a spherical gasket is arranged outside the planetary gear 5 7. There is a flat gasket 3 outside the side gear 2. The planetary gear 5 and the side gear 2 form a gear pair. The corresponding teeth on the gear pair have a three-tooth tooth structure. There are high teeth and two low teeth of the same height in sequence. There is a shallow groove 10 between the high teeth 8 and low teeth 9 on the side gear 2, and a deep groove 11 between the two low teeth 9. The high teeth on the planetary gear 5 A shallow groove 13 is formed between 14 and the low teeth 15, and a deep groove 12 is formed between two low teeth 15.

[0020] In this example, the change law of the speed rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com