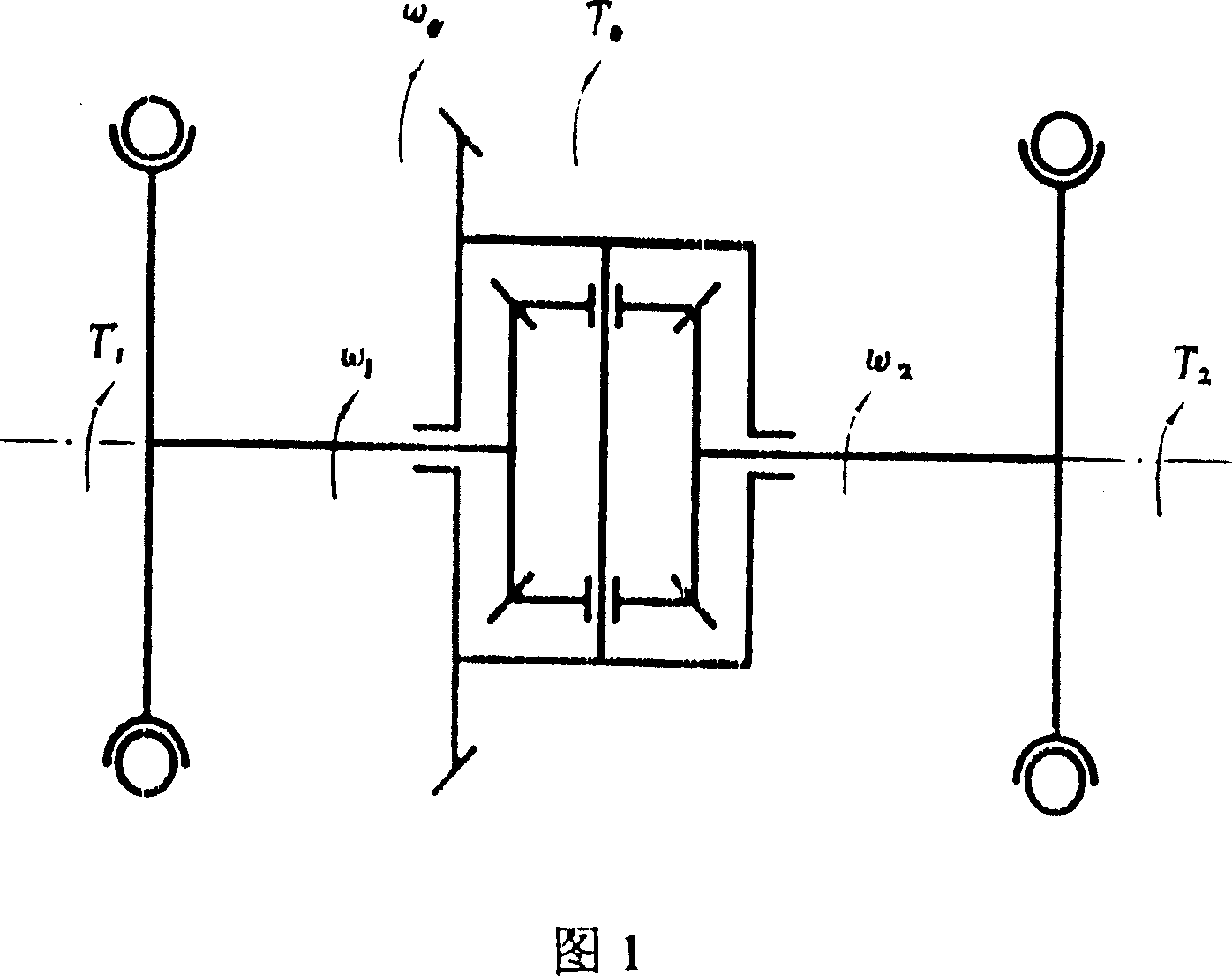

Anti-skid differential with adaptive speed ratio

A technology of anti-skid differential and gear ratio, applied in the direction of differential transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of small change range of transmission ratio, small change range, easy generation of pulsation and impact, etc. Achieve the effect of increasing the value variation range, reducing pulsation and impact, and increasing the locking coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

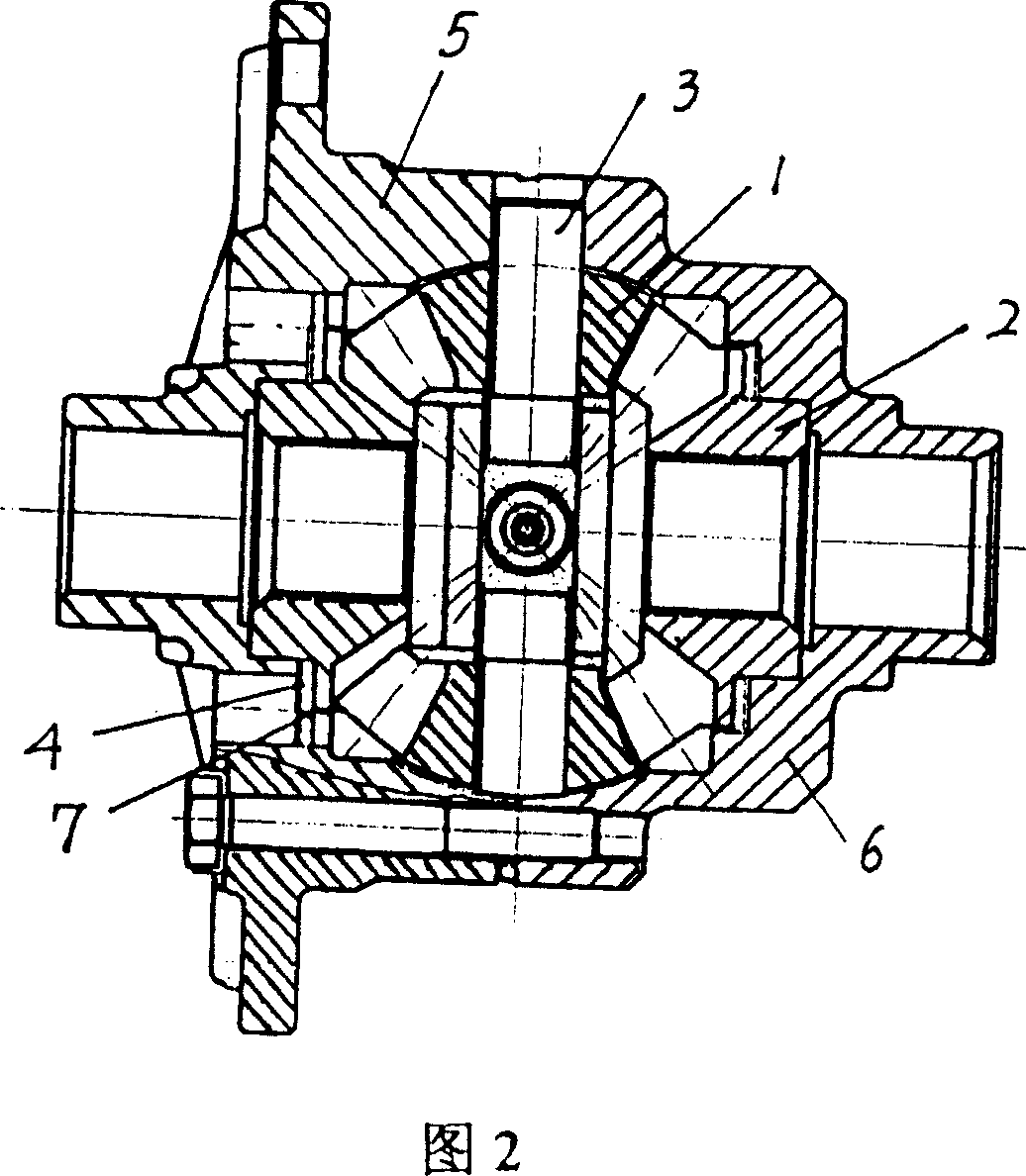

Embodiment 1

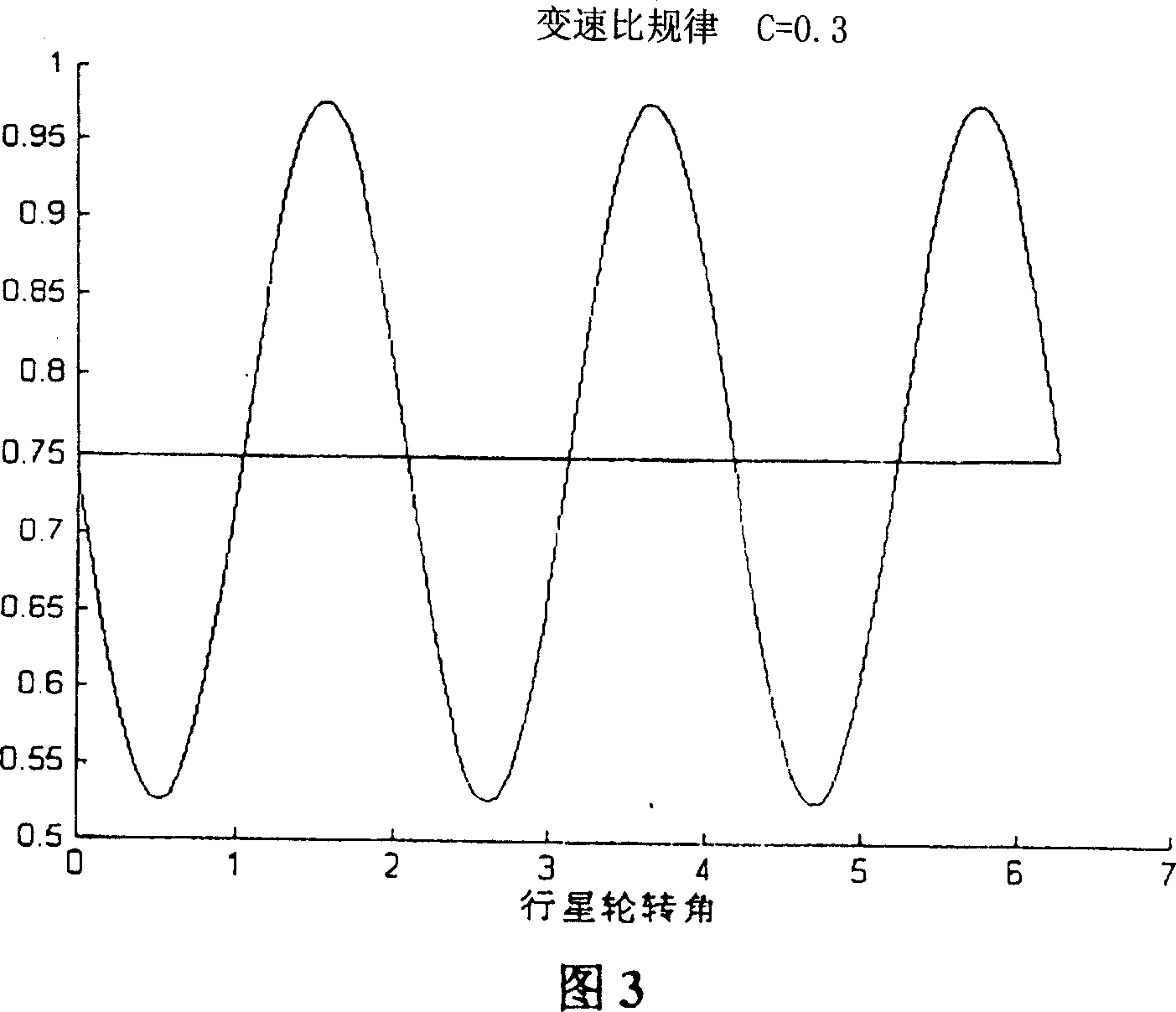

[0021] The adaptive variable ratio anti-slip differential device includes a differential case, 4 planetary gears 1, 2 side gears 2, a cross-shaped planetary gear shaft 3 and a disc spring 4. The differential case is composed of a left half case 5 and a right half case 6 with a cross hole in the middle. After the four planetary gears 1 are installed on the cross shafts of the planetary gear shaft 3 respectively, they are loaded into the differential case. A side gear 2, a disc spring 4 and a washer 7 are respectively installed in each cavity of the left half case 5 and the right half case 6 of the differential case, and then the left half case is fixed with 8 bolts. 5 and the right half shell 6 are connected into an integral structure. Planetary gear 1 has three speed ratio change periods per revolution. The transmission ratio of planetary gear 1 and side gear 2 satisfies:

[0022]

[0023] In the formula, 1 , 2 are the rotation angles of the planetary gear and the ...

Embodiment 2

[0025] The structure of the second embodiment of the adaptive variable ratio anti-slip differential is basically the same as that of the first embodiment. speed z 1 =9,z 1 =18 (that is, the ratio of the number of teeth of planetary gear 1 to the number of teeth of side gear 2 is 1:2), c=0.4, n=1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com