Bootstrap type hydraulic drive limiting slip differential

A limited-slip differential and hydraulic drive technology, which is applied to differential transmissions, transmissions, belts/chains/gears, etc., can solve the problem of low locking coefficient, reduced driving torque of half-axle wheels, and steering resistance Large and other problems, to achieve the effect of improving the locking coefficient, increasing internal friction, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with accompanying drawing:

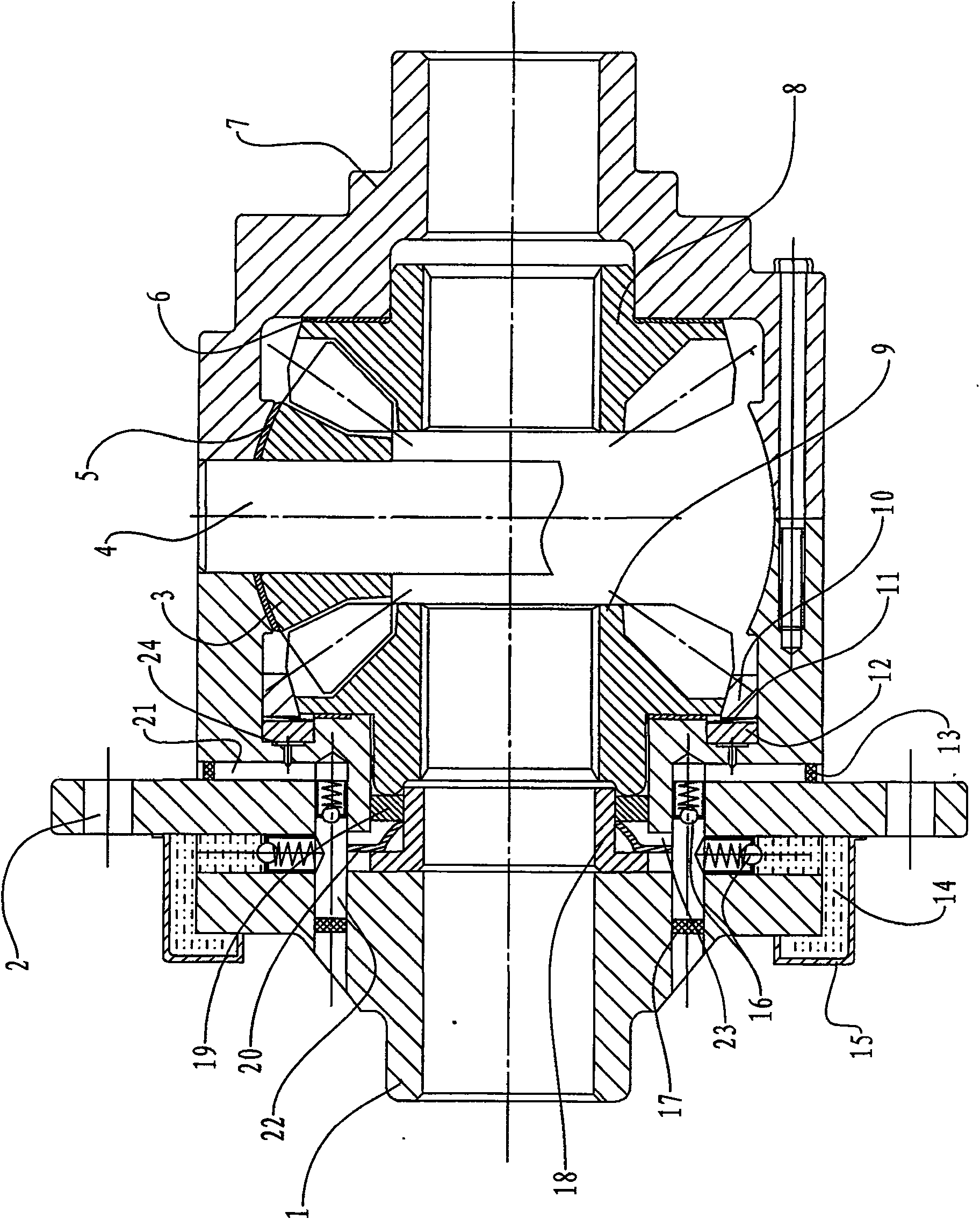

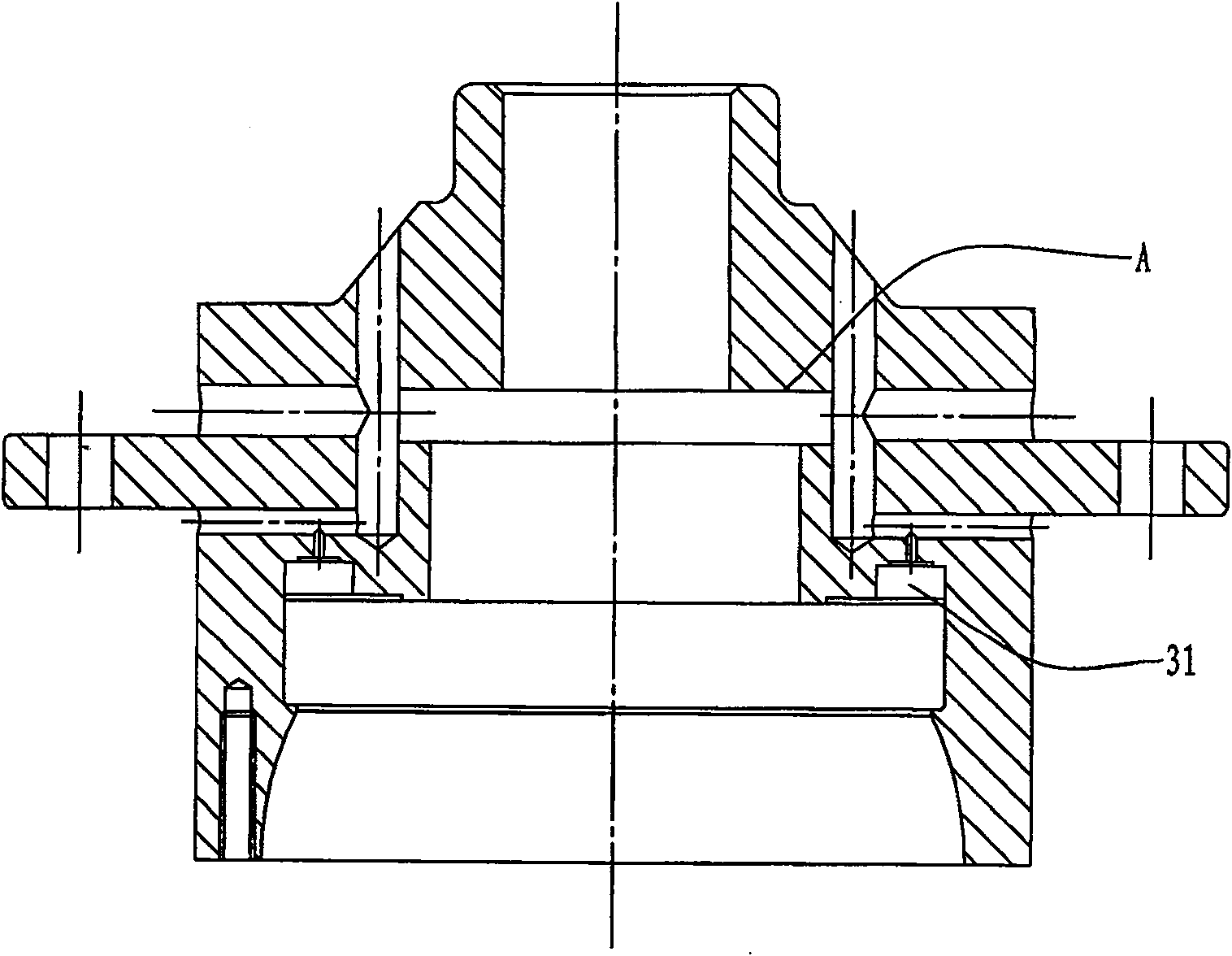

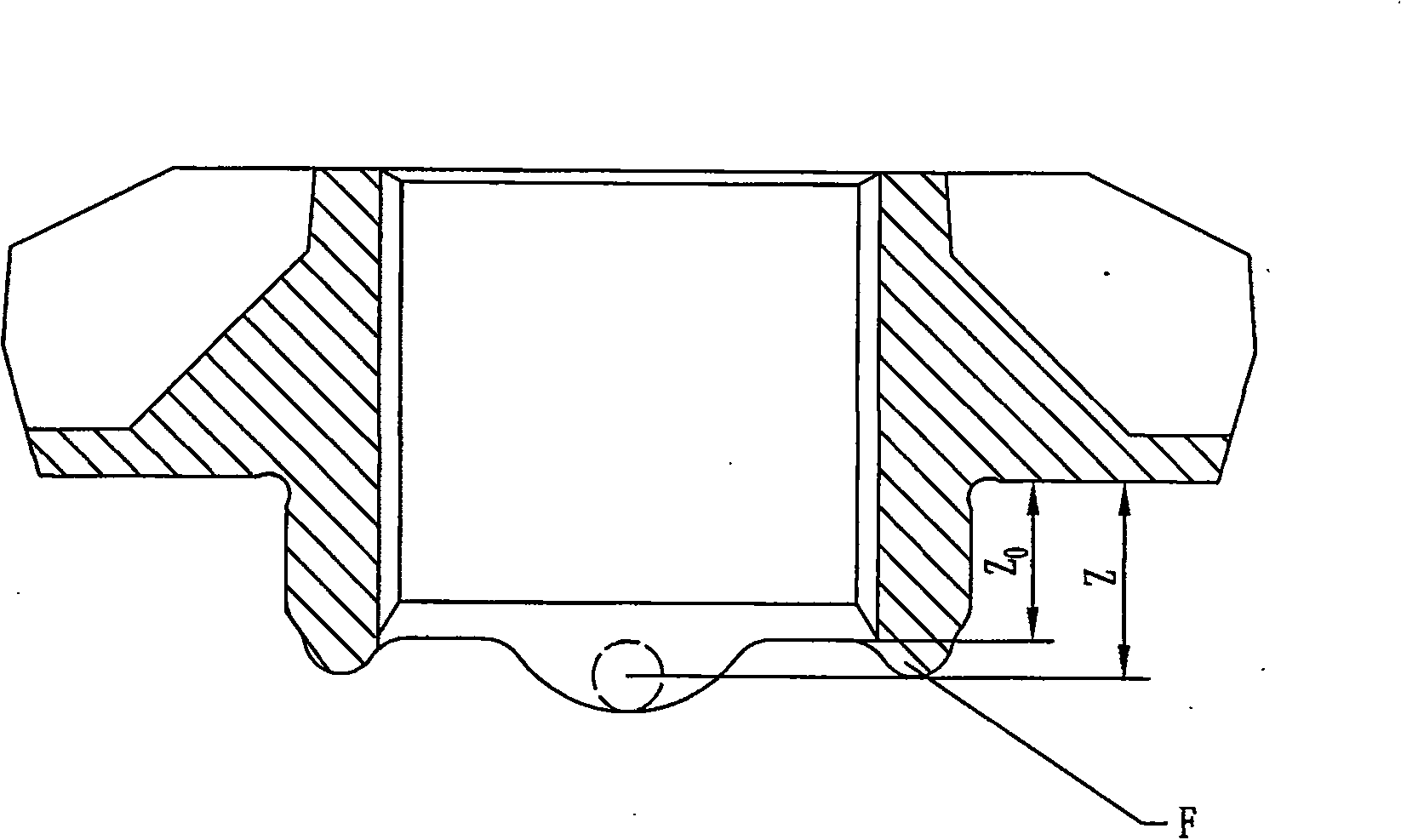

[0028] For the specific structure of this implementation example, see figure 1 . The present invention-a bootstrap hydraulic drive limited-slip differential, including the left and right housings and the differential assembly installed therein, the stepped end surface A inside the left housing 1 of the differential and the non-alignment of the side gear 9 The L-shaped pump sleeve 18 installed coaxially between the tooth end faces, the return spring 20, the piston 19, the piston 19 and the L-shaped pump sleeve 18 have a clearance fit, the piston 19 has a clearance fit with the left housing 1 of the differential, and the L-shaped pump Cover 18, return spring 20, and piston 19 constitute a piston pump; an oil inlet passage 14 and an oil outlet passage 21 are opened in the left housing 1 of the differential, and between the oil inlet passage 14 and the pressure chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com