High-temperature-resistant reinforced drilling and completion fluid and preparation method thereof

A technology of high temperature resistance, drilling and completion, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of loose foam system, leakage of foam network, poor temperature resistance of foam, etc., achieve good stability, slow down gas The effect of channeling and increasing internal friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

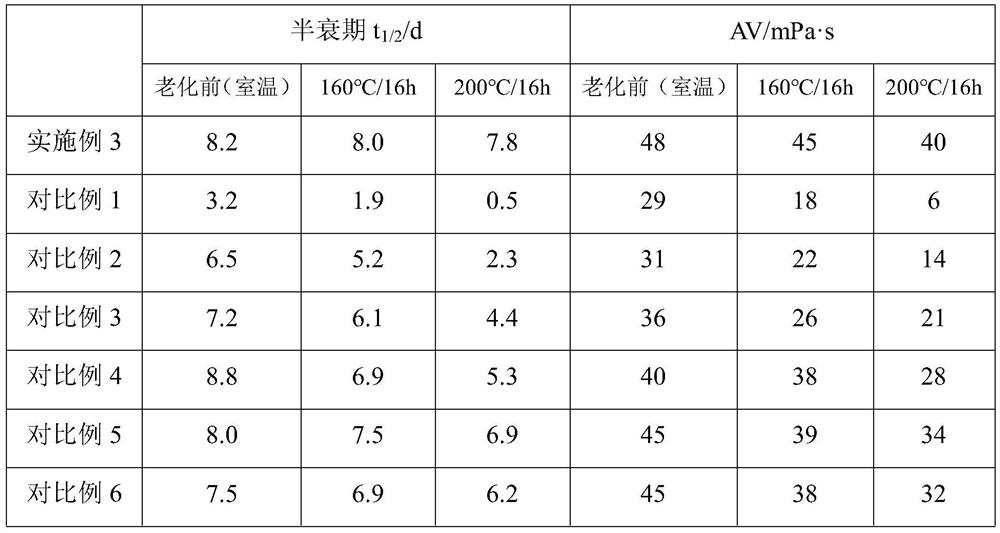

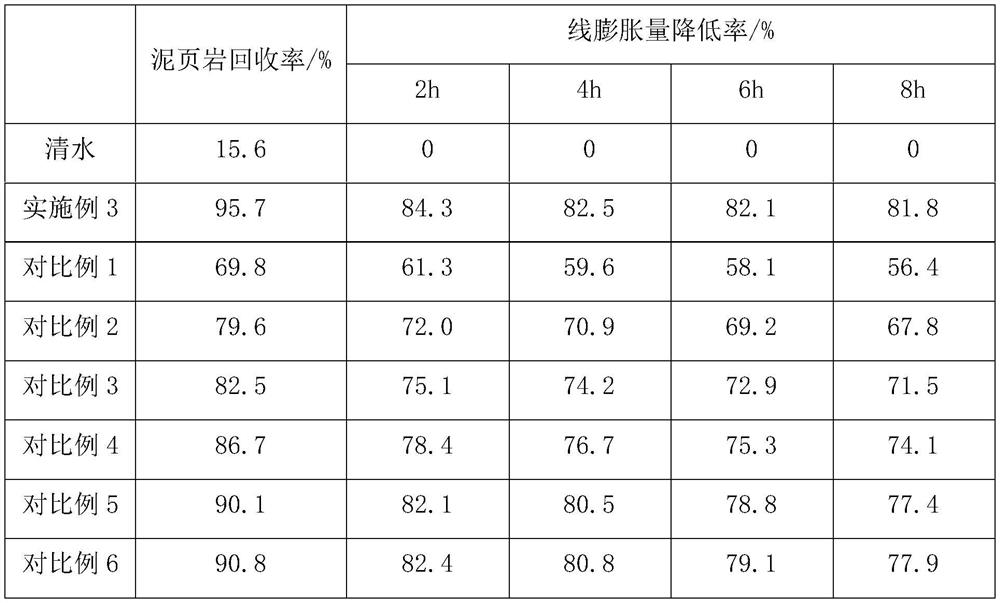

Examples

Embodiment 1

[0036] The invention provides a high-temperature-resistant enhanced drilling and completion fluid, which includes the following raw materials in parts by weight: 100 parts of base slurry, 0.6 parts of sodium dodecylsulfonate, and 0.6 parts of fatty alcohol polyoxyethylene ether sodium sulfate , 0.02 parts of carbodiamide urea, 0.04 parts of sodium nitrite, 0.06 parts of hydrotalcite, 0.3 parts of hydrolyzed polyacrylamide, 1.8 parts of graft copolymer with corrosion acid as the skeleton and 0.8 parts of modified yellow Raw gum;

[0037] The base slurry is an aqueous solution dispersed with modified nano-silicon dioxide particles, wherein the mass fraction of the modified nano-silicon dioxide particles is 0.3%; the preparation method of the modified nano-silicon dioxide particles is: by weight parts , take 60 parts of ethanol and 1 part of deionized water, mix them and place them under an ultrasonic oscillator for 20 minutes, then add 2.5 parts of tetraethyl orthosilicate to th...

Embodiment 2

[0049] The invention provides a high-temperature-resistant enhanced drilling and completion fluid, which includes the following raw materials in parts by weight: 150 parts of base slurry, 0.8 parts of sodium dodecylsulfonate, and 0.8 parts of fatty alcohol polyoxyethylene ether sodium sulfate , 0.04 parts of carbodiamide urea, 0.08 parts of sodium nitrite, 0.1 parts of hydrotalcite, 2 parts of hydrolyzed polyacrylamide, 2.4 parts of graft copolymer with corrosion acid as the skeleton and 1.2 parts of modified yellow Raw gum;

[0050] The base slurry is an aqueous solution dispersed with modified nano-silicon dioxide particles, wherein the mass fraction of the modified nano-silicon dioxide particles is 0.3%; the preparation method of the modified nano-silicon dioxide particles is: by weight parts , take 60 parts of ethanol and 1 part of deionized water, mix them and place them under the ultrasonic oscillator for 30 minutes, then add 2.5 parts of tetraethyl orthosilicate to the ...

Embodiment 3

[0062] The invention provides a kind of high-temperature-resistant enhanced drilling and completion fluid, which includes the following raw materials in parts by weight: 130 parts of base slurry, 0.7 parts of sodium dodecylsulfonate, and 0.7 parts of fatty alcohol polyoxyethylene ether sodium sulfate , 0.03 parts of carbodiamide urea, 0.06 parts of sodium nitrite, 0.08 parts of hydrotalcite, 1.2 parts of hydrolyzed polyacrylamide, 2.1 parts of graft copolymers with corrosion acid as the skeleton and 1.0 parts of modified yellow Raw gum;

[0063] The base slurry is an aqueous solution dispersed with modified nano-silicon dioxide particles, wherein the mass fraction of the modified nano-silicon dioxide particles is 0.3%; the preparation method of the modified nano-silicon dioxide particles is: by weight parts , take 60 parts of ethanol and 1 part of deionized water, mix them and put them under the ultrasonic oscillator for 25 minutes, then add 2.5 parts of tetraethyl orthosilica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com