Flame-retardant wide-temperature-range high damping composite material and preparation method thereof

A composite material and wide temperature range technology, applied in the field of flame retardant wide temperature range high damping composite material and its preparation, can solve the problems of flammability, increase vehicle safety hazards, combustion support, etc., to reduce energy consumption and broaden the use of damping Excellent temperature range and flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

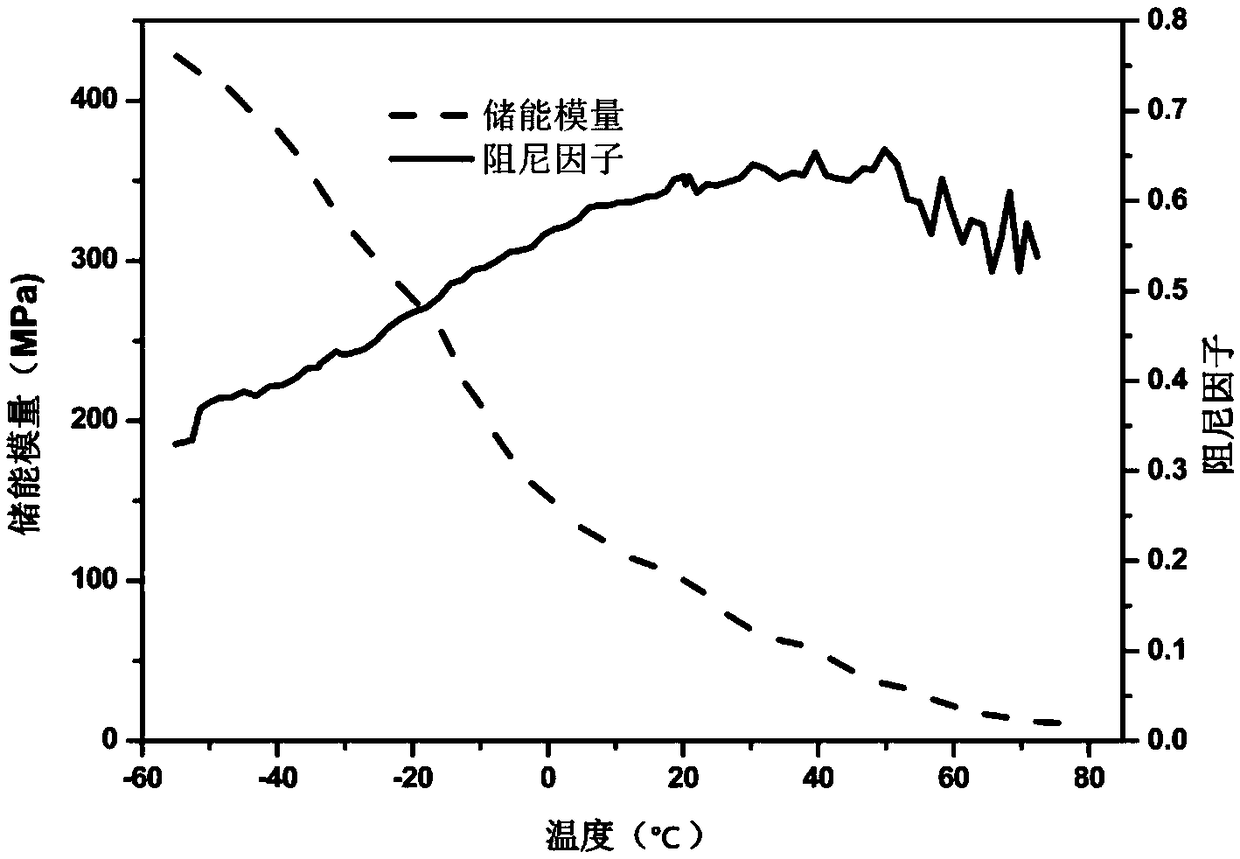

Image

Examples

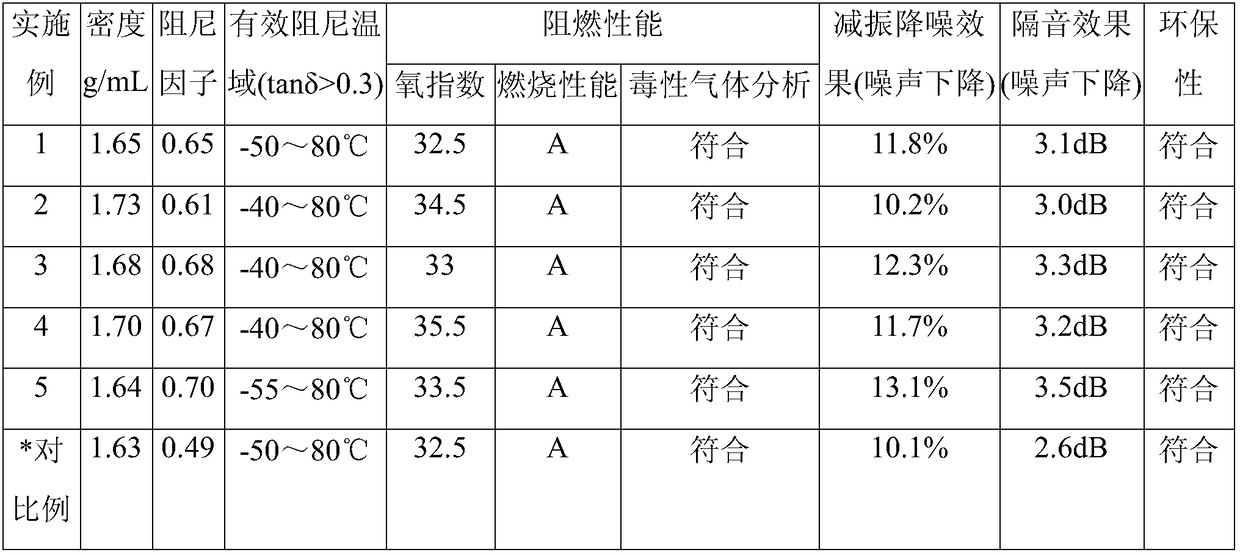

Embodiment 1

[0043] A flame retardant wide temperature range high damping composite material, the components it includes and the mass ratio of each component are: butyl rubber is 1000g; 70# petroleum asphalt is 1000g; flame retardant is 1500g, reinforcing agent is 1500g, anti-aging agent AW (6-ethoxy-2,2,4-trimethyl-1,2-dihydroquinoline) is 10g; vulcanization system is 100g; KH550 is 30g; contains phthalein Cardo and nitrile structure 50 g of the bismaleimide resin, wherein the number average molecular weight of the bismaleimide resin containing phthalein-cardo and nitrile structure is 2100.

[0044] Among them, the flame retardant is a compound of aluminum hydroxide, magnesium hydroxide, melamine, and ammonium polyphosphate, according to the mass ratio: aluminum hydroxide: magnesium hydroxide: melamine: ammonium polyphosphate = 100:5:5: 20;

[0045] The reinforcing agent is a compound of mica flakes, vermiculite, short carbon fibers and carbon black; according to the mass ratio, mica fla...

Embodiment 2

[0056] A flame retardant wide temperature range high damping composite material, the components it includes and the mass ratio of each component are: butyl rubber is 250g, neoprene is 250g; 100# petroleum asphalt is 1000g; flame retardant is 1500g, reinforcing agent 1500g, antioxidant D (N-phenyl-2-naphthylamine) 15g; curing system 100g; KH550 15g; KH560 10g; The amine resin is 50 g, wherein, the number average molecular weight of the bismaleimide resin containing phthalein-based Cardo and nitrile structure is 2000.

[0057] Among them, the flame retardant is a compound of aluminum hydroxide, magnesium hydroxide, melamine, and ammonium polyphosphate, according to the mass ratio: aluminum hydroxide: magnesium hydroxide: melamine: ammonium polyphosphate = 100:5:5: 20;

[0058] The reinforcing agent is a compound of mica flakes, vermiculite, short carbon fibers and carbon black; according to the mass ratio, mica flakes: vermiculite: short carbon fibers: carbon black = 100:5:5:20...

Embodiment 3

[0068] A flame retardant wide temperature range high damping composite material, the components it includes and the mass ratio of each component are: butyl rubber is 250g; nitrile-based rubber is 250g; 100# petroleum asphalt is 700g, and 30# petroleum asphalt is 300g; flame retardant 1000g, reinforcing agent 1000g, antioxidant RD 10g; antioxidant 4020 5g; vulcanization system 100g; KH570 20g; Resin is 30g, wherein, the number average molecular weight of bismaleimide resin containing phthalein-cardo and nitrile structure is 2500.

[0069] Among them, the flame retardant is a compound of aluminum hydroxide, magnesium hydroxide, melamine, and ammonium polyphosphate, according to the mass ratio: aluminum hydroxide: magnesium hydroxide: melamine: ammonium polyphosphate = 100:5:5: 30;

[0070] The reinforcing agent is a compound of mica flakes, vermiculite, short carbon fibers and carbon black; according to the mass ratio, mica flakes: vermiculite: short carbon fibers: carbon black...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com