Hairbrush, bristle, and method for the production thereof

A technology of bristles and hairs, which is applied in the field of manufacturing hair brushes and such bristles, and can solve the problems of not being able to make bristle feet, not allowing the operator to choose the bristle feet, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

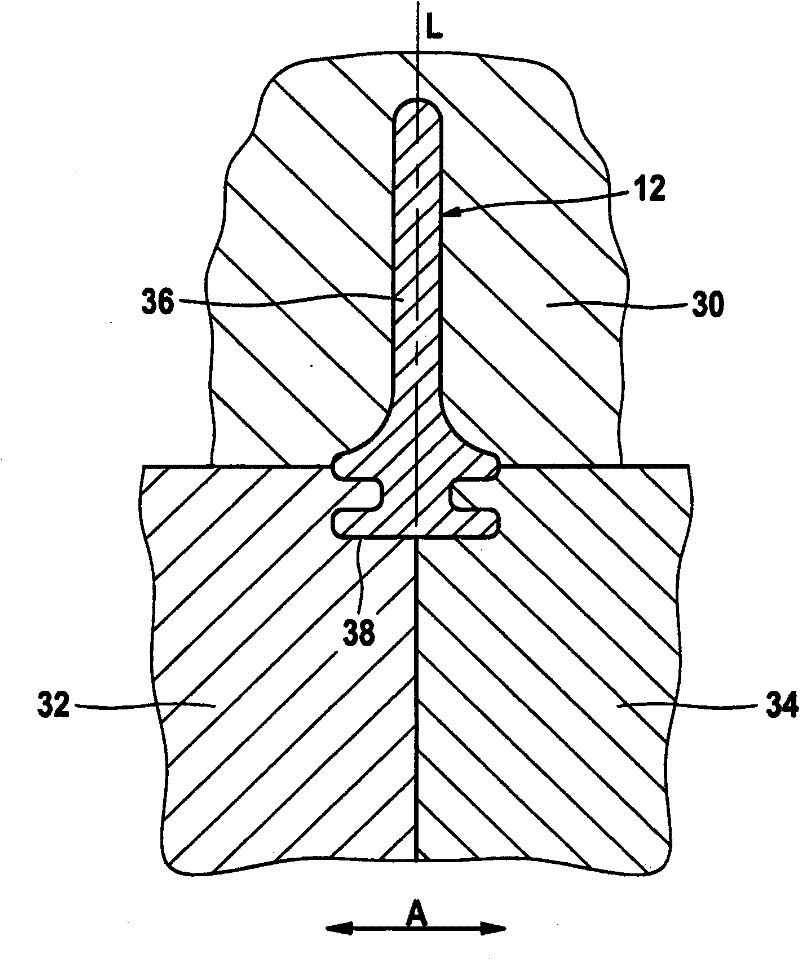

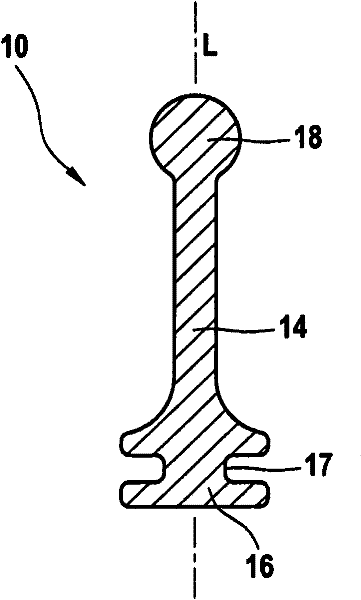

[0032] figure 1 A longitudinal section of the bristle 10 is shown, which is selected along the longitudinal axis L of the bristle. A bristle shaft blank 12 can be seen here, which has a bristle shaft 14 , a bristle foot 16 and a bristle head 18 . The bristle shaft blank is formed in the hollow space 36 of the first molding fixture 30 . The second molding fixture 32 and the third molding fixture 34 form a hollow space 38 in which the bristle feet 16 are formed. The bristle shaft blank can be removed from the molding fixture by moving the first molding fixture 30 along the longitudinal axis L, i.e., as figure 1 Move up as shown. The second and third molding jigs are then pulled apart in a direction perpendicular to the longitudinal axis L as indicated by left and right arrows A .

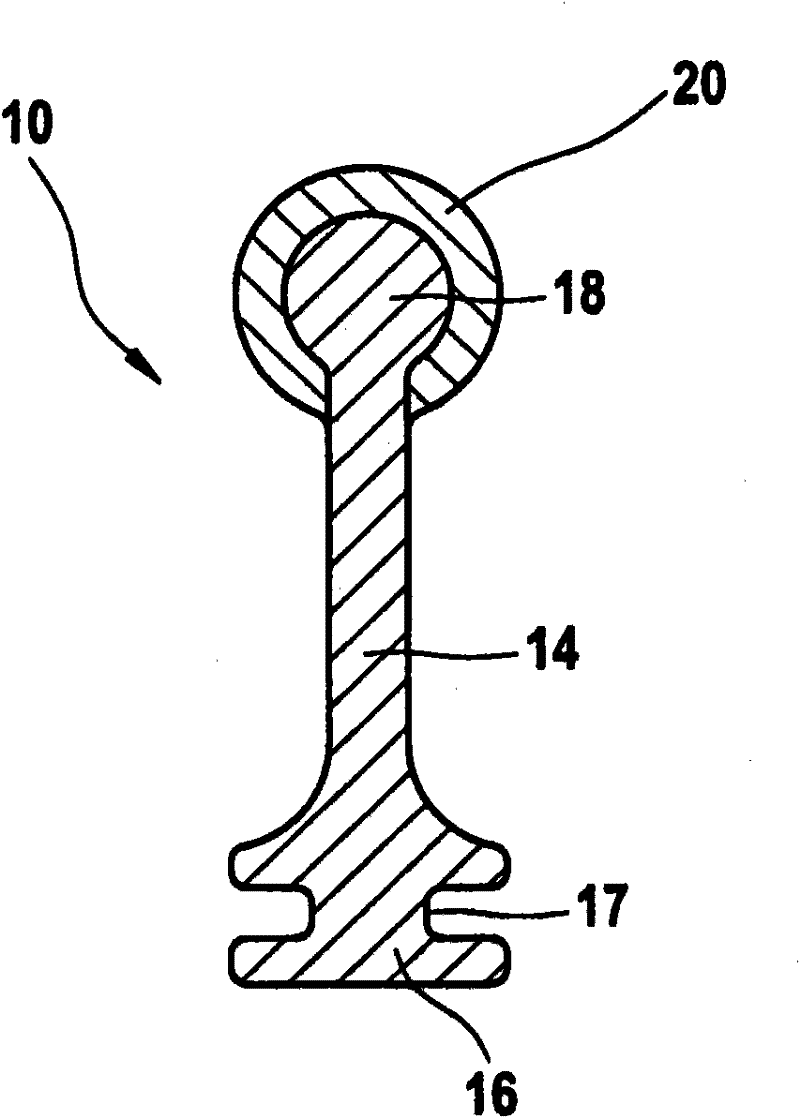

[0033] figure 2 A bristle 10 is shown that may be manufactured according to the methods disclosed herein. The shaft 14 of the bristle 10 is free of ridges and is bounded above by the bristle he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com