Thin paper winding device with planet breaking mechanisms and thin paper breaking method thereof

A technology of planetary wheels and paper rolls, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of lower product quality, uneven tear lines, etc., and achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments adopted by the present invention will be further described by the following embodiments and accompanying drawings.

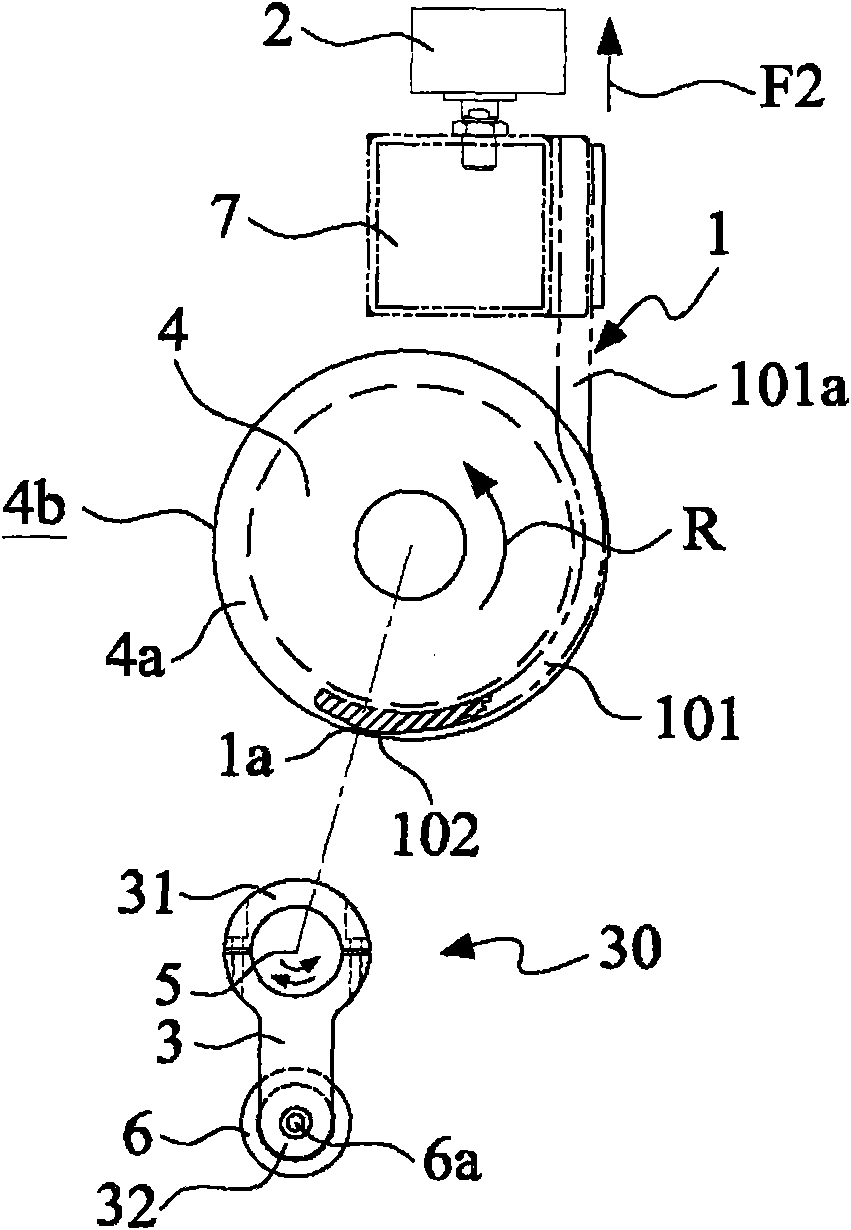

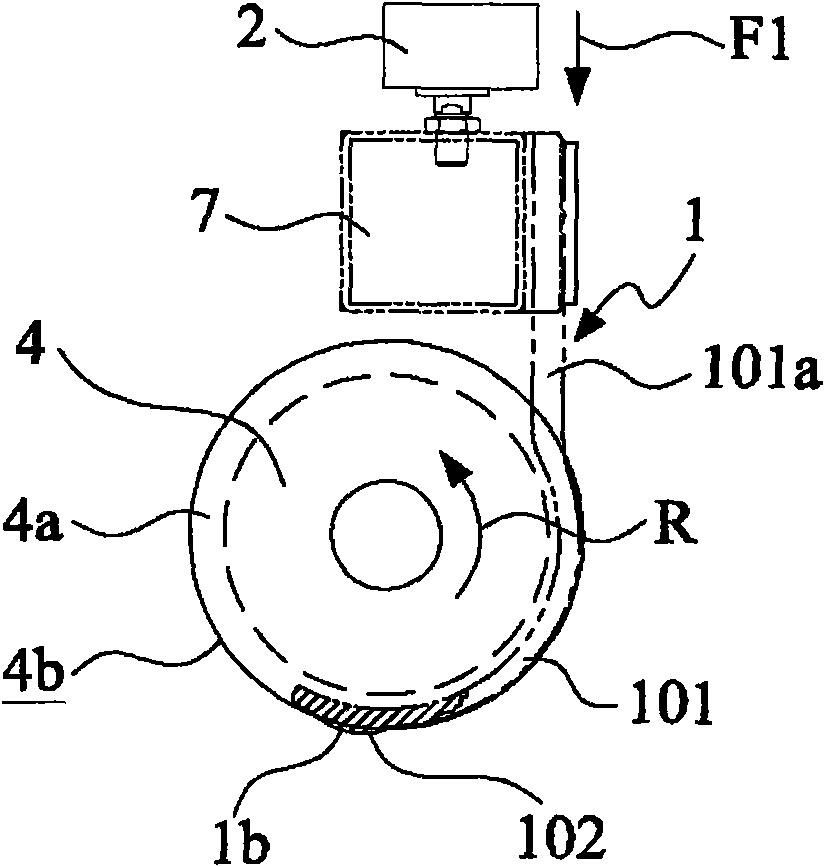

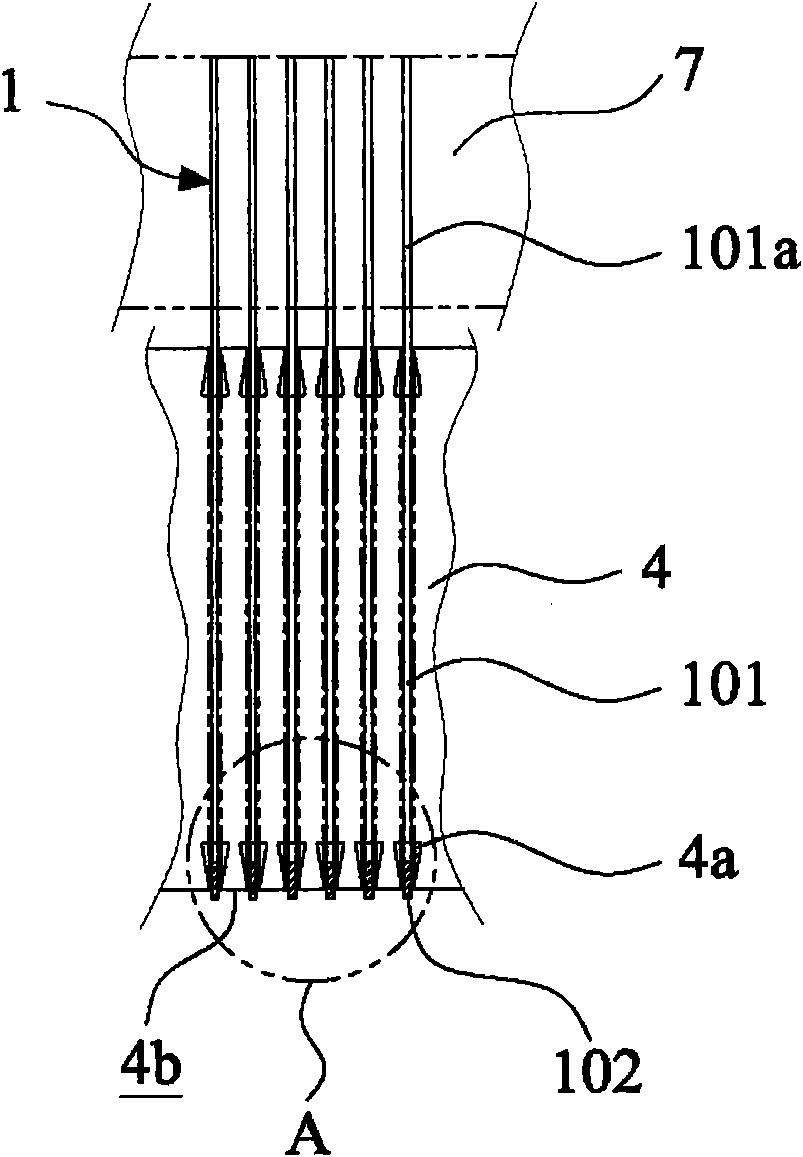

[0036] Please also see Figure 1 to Figure 8 As shown, the thin paper winding device 200 of the present invention having a planetary wheel breaking mechanism includes an upper winding wheel 4, a plurality of arc-shaped guide plates 8 (please also refer to Figure 8 ), a plurality of branch cutting arms 1 and a set of planetary wheel breaking mechanism 30, the planetary wheel breaking mechanism 30 includes a plurality of branch wheel rotating arms 3 and a plurality of planetary wheels 6. Wherein the winding wheel 4 rotates in a predetermined direction R, and the round surface 4b of the winding wheel 4 is provided with a plurality of grooves 4a, and a plurality of arc-shaped guide plates 8 are arranged at a predetermined distance below the winding wheel 4, and The wheel surface 4b of the winding wheel 4 forms an arc-shaped passage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com