Thin film deposition apparatus

A thin-film deposition device and thin-film technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of fine organic thin film formation, difficult manufacturing of driving voltage, current density, color purity, and large luminous efficiency Organic light-emitting display devices, problems such as difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

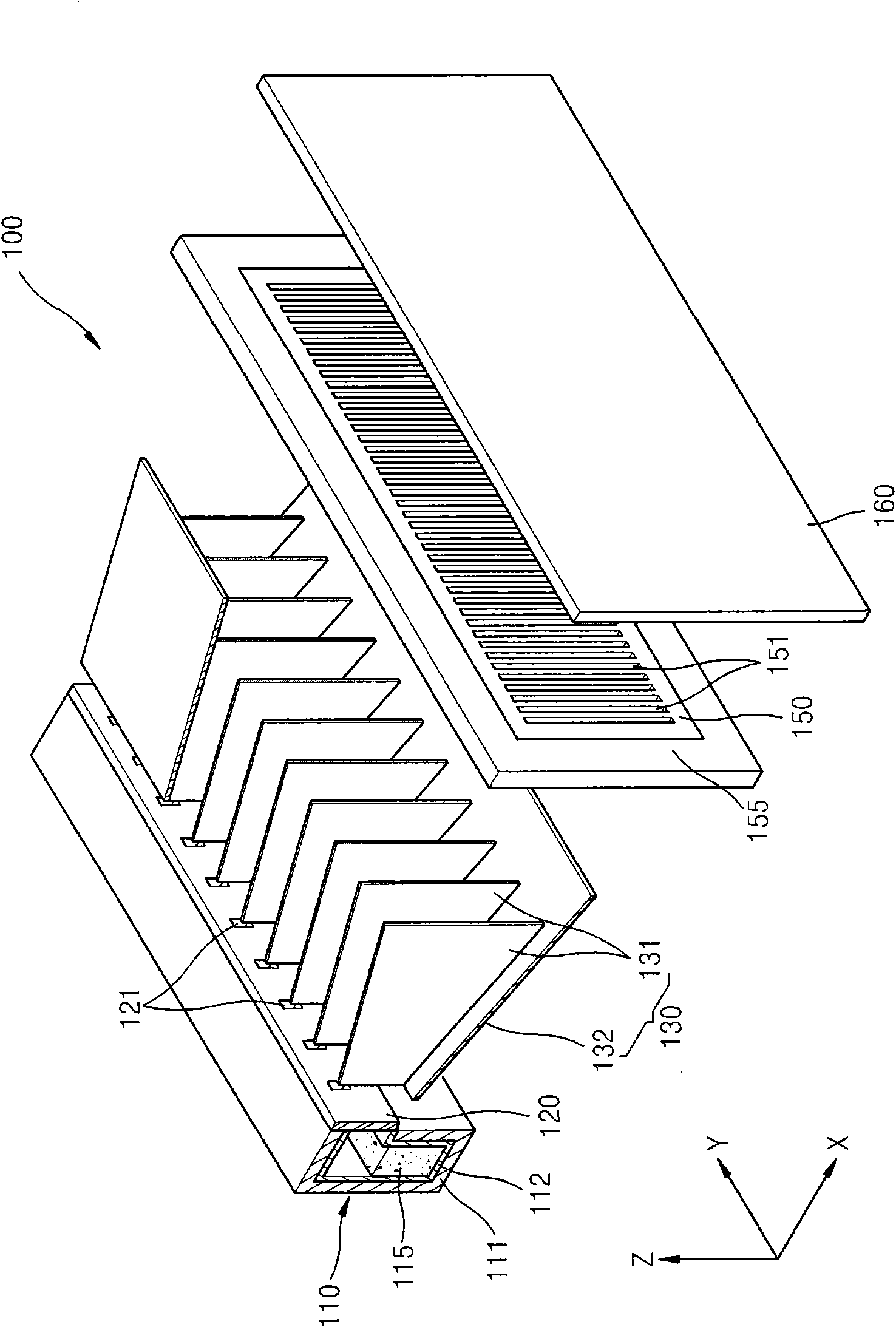

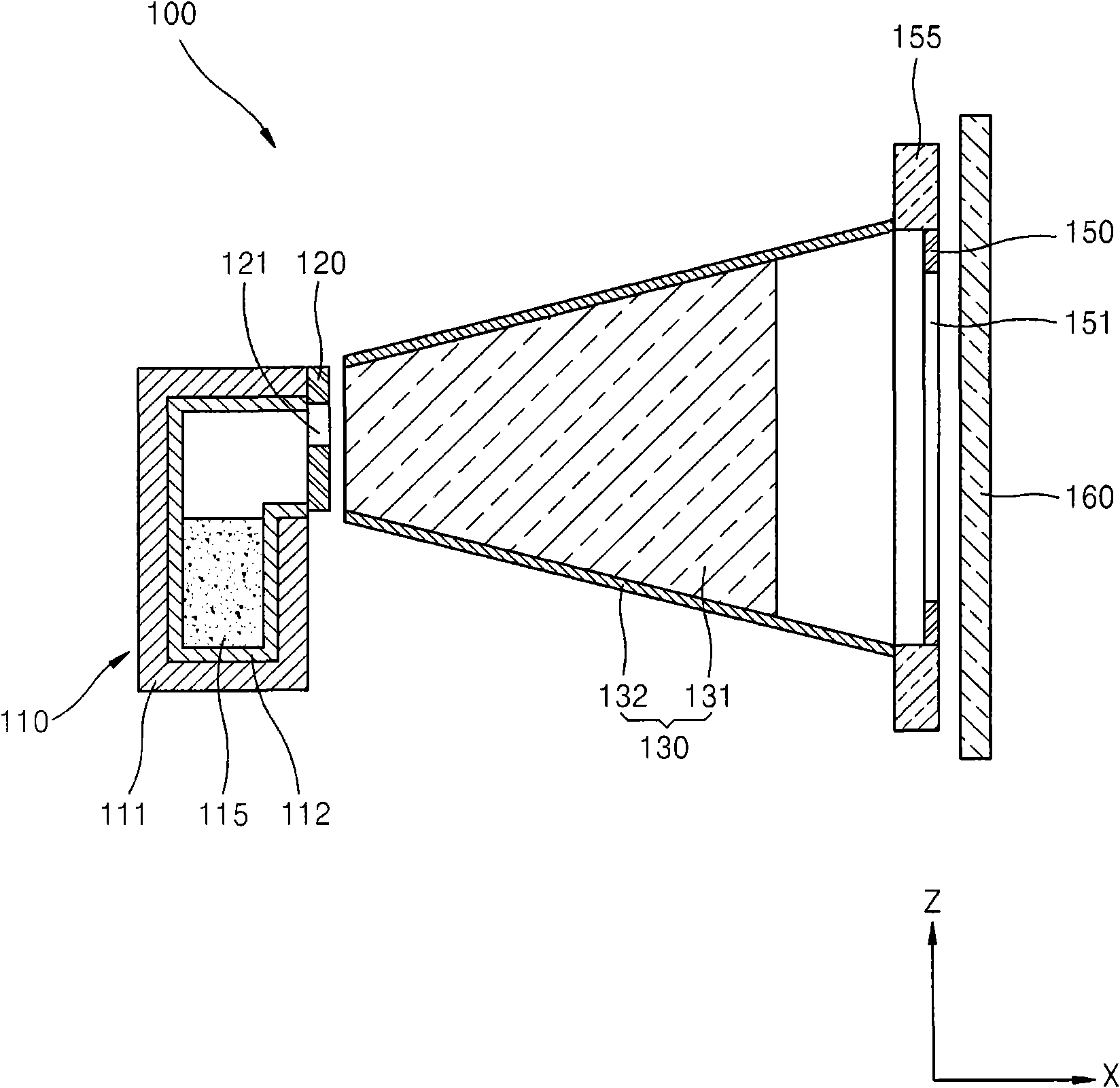

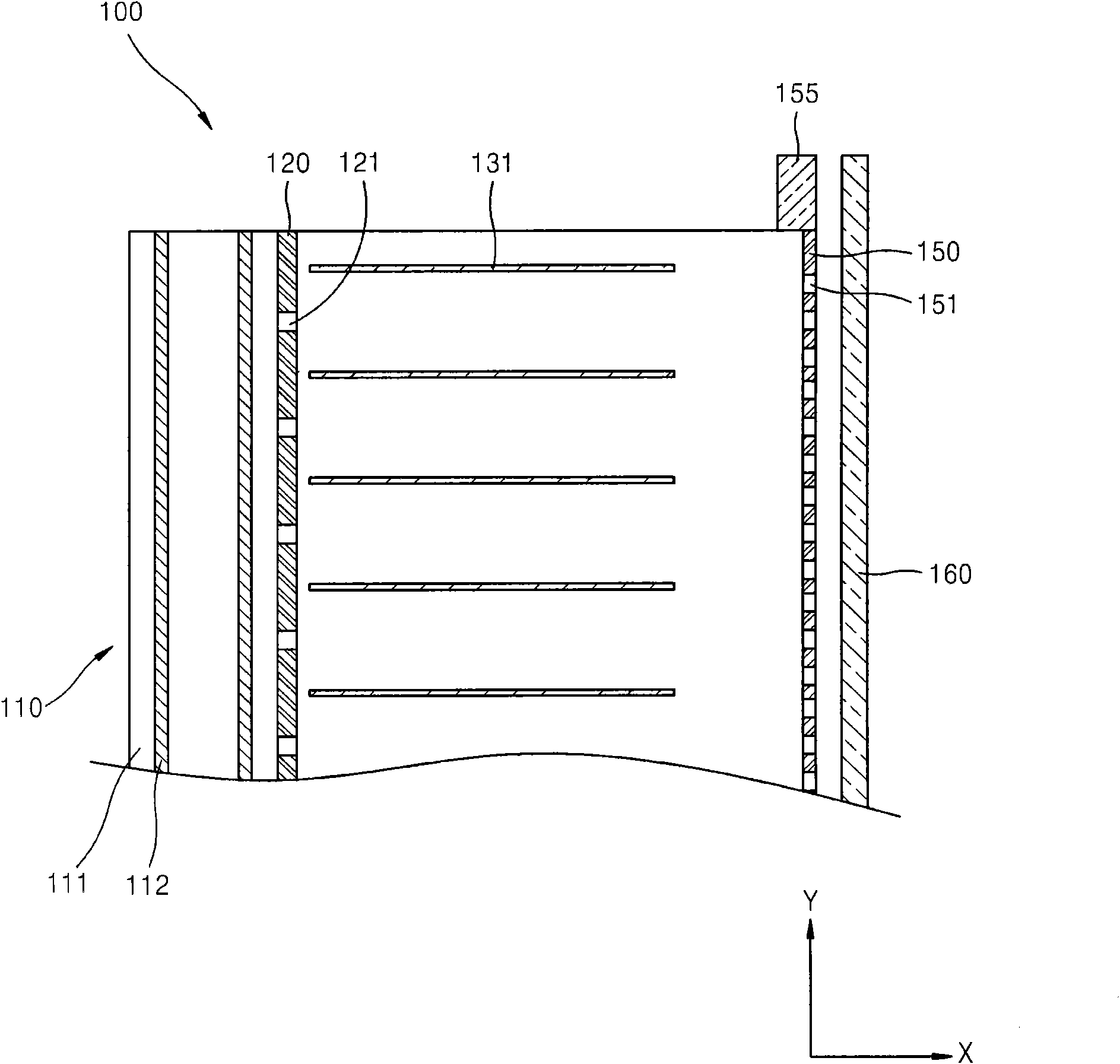

[0089] figure 1 is a schematic perspective view of a thin film deposition apparatus 100 according to an embodiment of the present invention, figure 2 is a schematic side view of the thin film deposition apparatus 100, image 3 is a schematic plan view of the thin film deposition apparatus 100 .

[0090] refer to figure 1 , figure 2 and image 3 , the thin film deposition apparatus 100 according to the current embodiment of the present invention includes a deposition source 110 , a first nozzle 120 , a barrier wall assembly 130 , a second nozzle 150 , a second nozzle frame 155 and a substrate 160 . The thin film deposition apparatus 100 according to the current embodiment of the present invention further includes an interval control member (see Figure 7 ) and alignment control member (see Figure 7 ). will refer to later Figure 7 to Figure 9B The interval control member and the alignment control member will be described in detail.

[0091] Although for ease of expl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com