Device and method for checking electrotype intaglios

A technology for inspection devices and inspection methods, applied in measuring devices, material analysis through optical means, instruments, etc., can solve problems that have not been applied, and achieve the effect of solving the problem of mirror reflection on the layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be further described in detail below in conjunction with the drawings and specific examples.

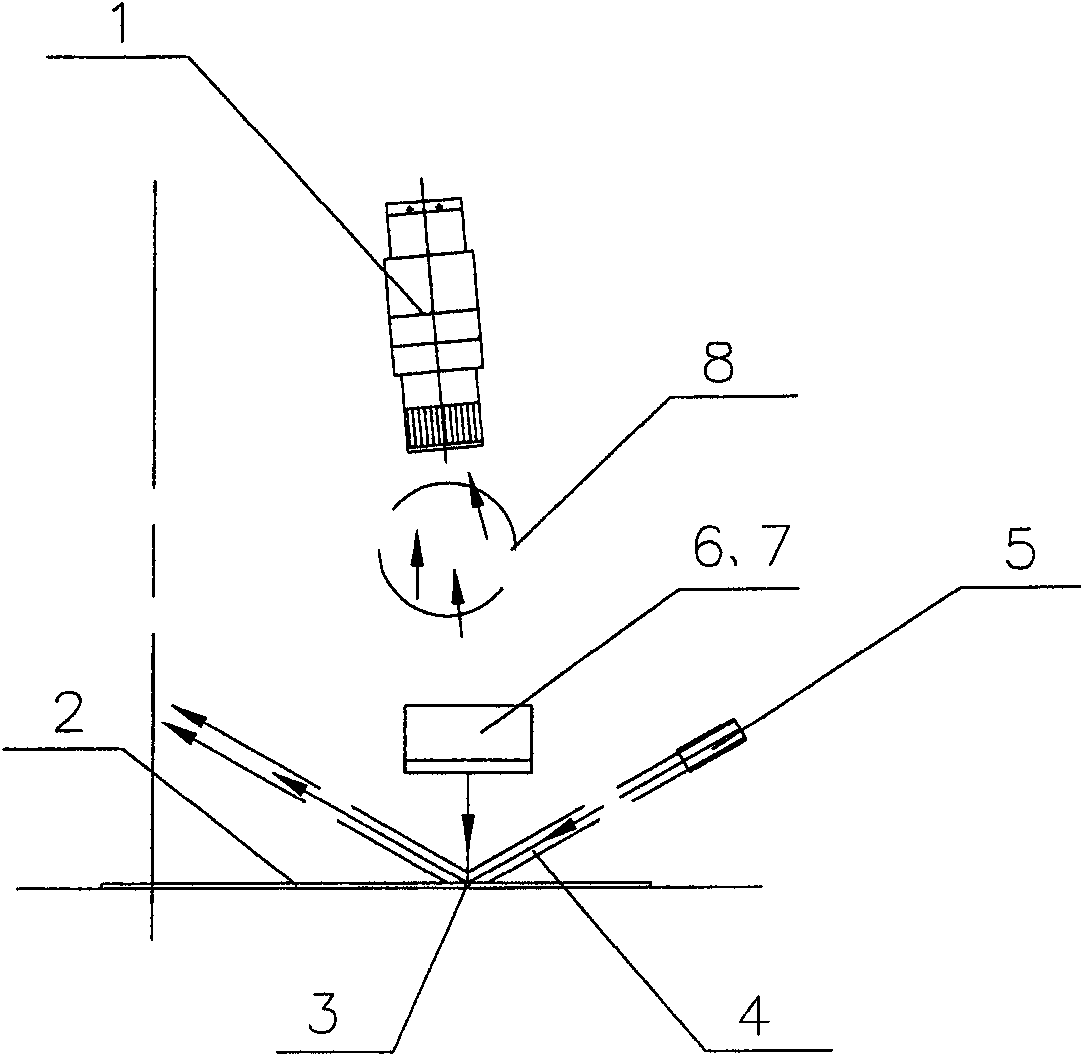

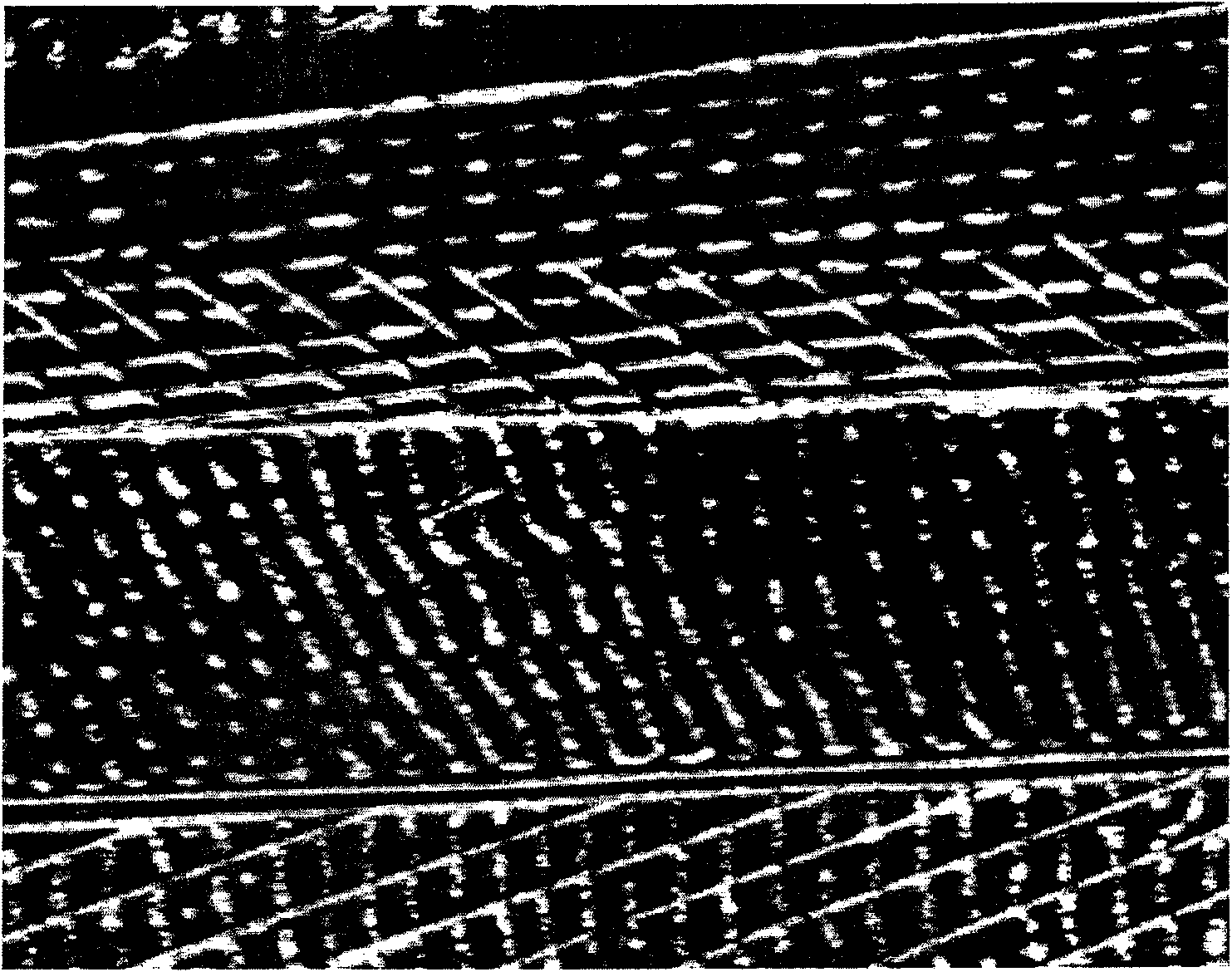

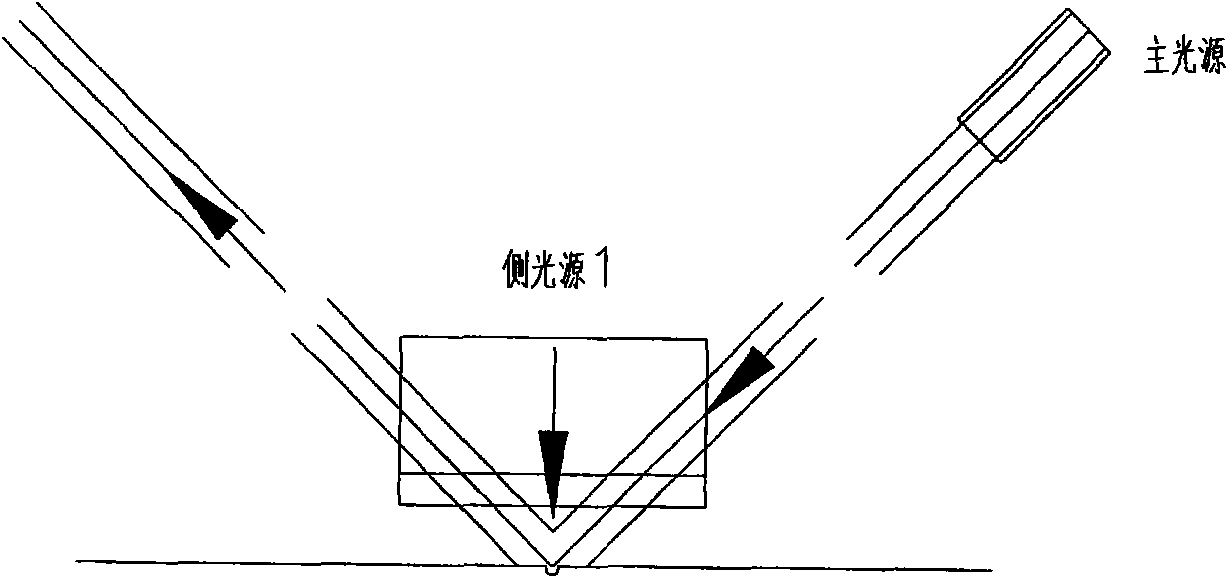

[0022] The invention relates to an electroforming gravure pattern inspection device. The pattern of the electroformed gravure is pit-shaped stripes recessed below the layout, and the two walls of the pit-shaped stripes are diffuse reflection surfaces. The device mainly includes: The camera above the plate; and the light source module, the light emitted by the light source module has an included angle with the plate, so that the light shining on the plate plane does not enter the camera lens after reflection, and the image is dark; Because it is a pit-shaped stripe that is recessed below the layout, and the two walls of the pit-shaped stripe are diffuse reflection surfaces, so the light that shines on the pattern can be reflected into the camera, and images of different grayscales are formed for different depths of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com