Stainless steel roll-grinding hot-pasting laser cutting protective film and preparation process thereof

A laser cutting, stainless steel technology, applied in the direction of film/sheet adhesive, adhesive type, ester copolymer adhesive, etc., to solve focusing and reflection problems, strong cohesive strength and stability, initial good sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

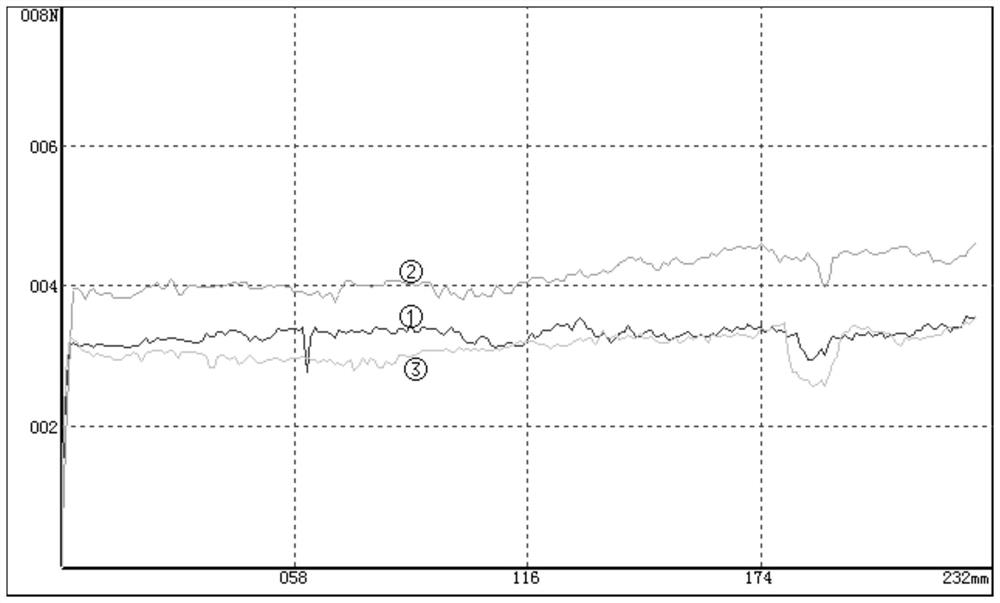

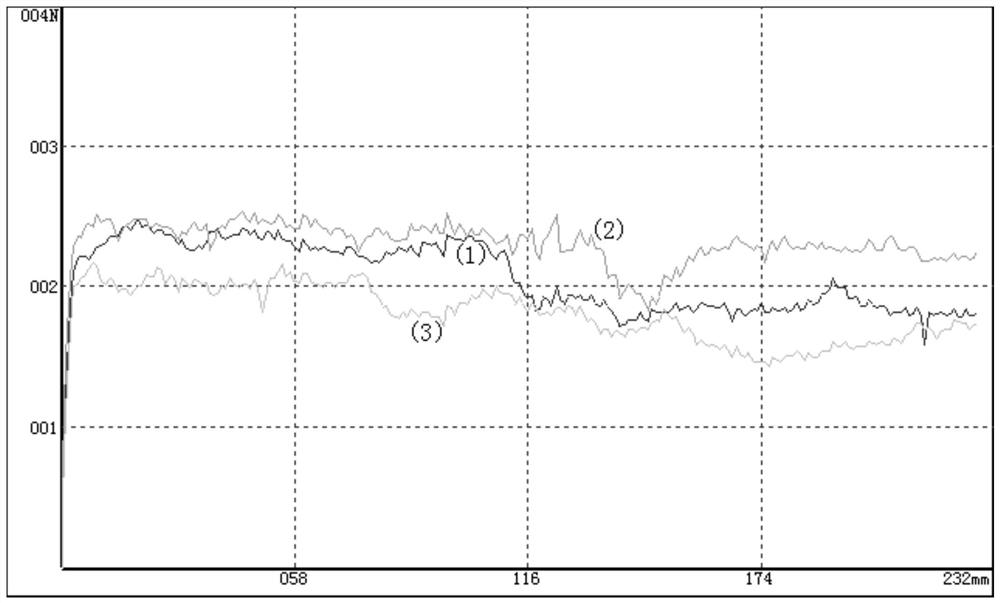

Image

Examples

Embodiment 1

[0021] A protective film for laser cutting of stainless steel coils, made of the following raw materials according to weight percentage: 30% low-density polyethylene, 40% linear polyethylene, 10% metallocene, 10% high-density polyethylene, special coloring masterbatch Granules 10%.

[0022] The glue is made of the following raw materials according to weight percentage: 4% acrylic acid, 25% butyl acrylate, 50% isooctyl acrylate, 11% vinyl acetate, 5% methyl methacrylate, and 5% hydroxyethyl acrylate.

[0023] A kind of preparation technology of stainless steel roll grinding thermal paste laser cutting protective film comprises the following steps:

[0024] (1) Substrate preparation: mix 30% low-density polyethylene, 40% linear polyethylene, 10% metallocene, 10% high-density polyethylene, and 10% special coloring masterbatch, and use melt co-extrusion blow molding Process to make the base material, the temperature of the main engine of the blow molding unit is 160 degrees, the ...

Embodiment 2

[0033] A protective film for laser cutting of stainless steel coils, made of the following raw materials according to weight percentage: 30% low-density polyethylene, 40% linear polyethylene, 10% metallocene, 10% high-density polyethylene, special coloring masterbatch Granules 10%.

[0034] The glue is made of the following raw materials according to weight percentage: 4% acrylic acid, 25% butyl acrylate, 50% isooctyl acrylate, 11% vinyl acetate, 5% methyl methacrylate, and 5% hydroxyethyl acrylate.

[0035] A kind of preparation technology of stainless steel roll grinding thermal paste laser cutting protective film comprises the following steps:

[0036] (1) Substrate preparation: mix 30% low-density polyethylene, 40% linear polyethylene, 10% metallocene, 10% high-density polyethylene, and 10% special coloring masterbatch, and use melt co-extrusion blow molding Process to make the base material, the main machine temperature of the blow molding unit is 190 degrees, the die te...

Embodiment 3

[0045] A protective film for laser cutting of stainless steel coils, made of the following raw materials according to weight percentage: 35% low-density polyethylene, 38% linear polyethylene, 10% metallocene, 7% high-density polyethylene, special coloring masterbatch Granules 10%.

[0046] The glue is made of the following raw materials according to weight percentage: 4% acrylic acid, 25% butyl acrylate, 50% isooctyl acrylate, 11% vinyl acetate, 5% methyl methacrylate, and 5% hydroxyethyl acrylate.

[0047] A kind of preparation technology of stainless steel roll grinding thermal paste laser cutting protective film comprises the following steps:

[0048] (1) Substrate preparation: mix 34% low-density polyethylene, 38% linear polyethylene, 10% metallocene, 7% high-density polyethylene, and 10% special coloring masterbatch, and use melt co-extrusion blow molding Process to make the base material, the temperature of the main machine of the blow molding unit is 175 degrees, the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com