1% osmium tetroxide fixative and preparation method thereof

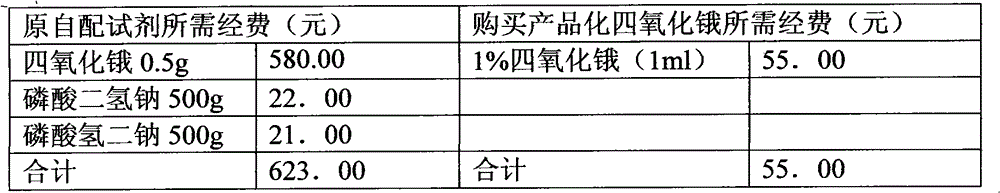

A technology of osmium tetroxide and fixative, applied in the field of 1% osmium tetroxide fixative and its preparation, can solve the problems of waste of resources, waste of experiment funds, environmental pollution, etc., and achieve the effect of guaranteeing quality and improving experiment quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A kind of preparation method of 2.5% glutaraldehyde fixative used in electron microscope experiment of the present invention, concrete technological process is as follows: Technical process: raw material, auxiliary material inspection-professional preparation---intermediate inspection---filter---subpackage, Fusion sealing --- light inspection --- packaging --- finished product inspection.

[0034] 1. Raw and auxiliary materials:

[0035] Raw materials, auxiliary materials, equipment

[0036] 2. Preparation process:

[0037] 1) Phosphate buffer preparation:

[0038] Liquid A: disodium hydrogen phosphate * 12 crystal water 71.64g, add distilled water to 1000ml;

[0039] Liquid B: Sodium dihydrogen phosphate * 2 crystal water 31.21g, add distilled water to 1000ml;

[0040] Configure 0.2mol PH7.2 buffer solution: A solution 36ml + B solution 14ml;

[0041] 2) Preparation of fixative osmium tetroxide:

[0042] Mix 50ml of 0.2mol pH7.2 buffer + 1g of osmium tet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com