Method for treating and cleaning corroded and oxidized surface defects

A defect treatment and defect technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of scratching the surface of the fracture, not wiping, bumping, etc., to achieve simple and convenient operation and retention. The original appearance and the effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

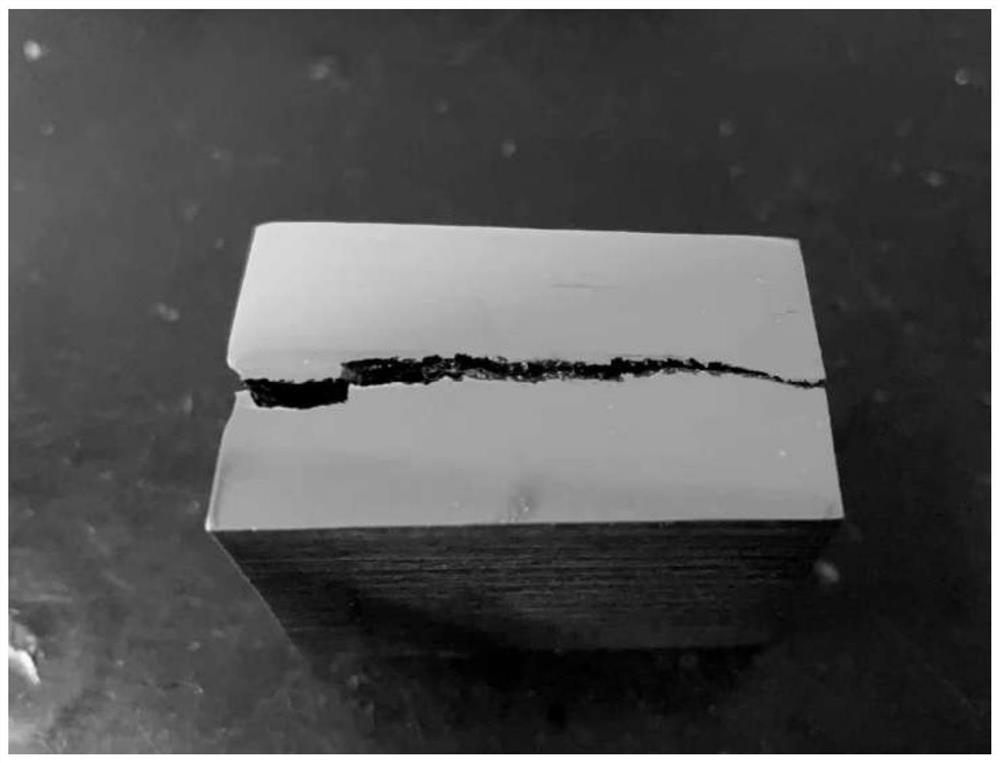

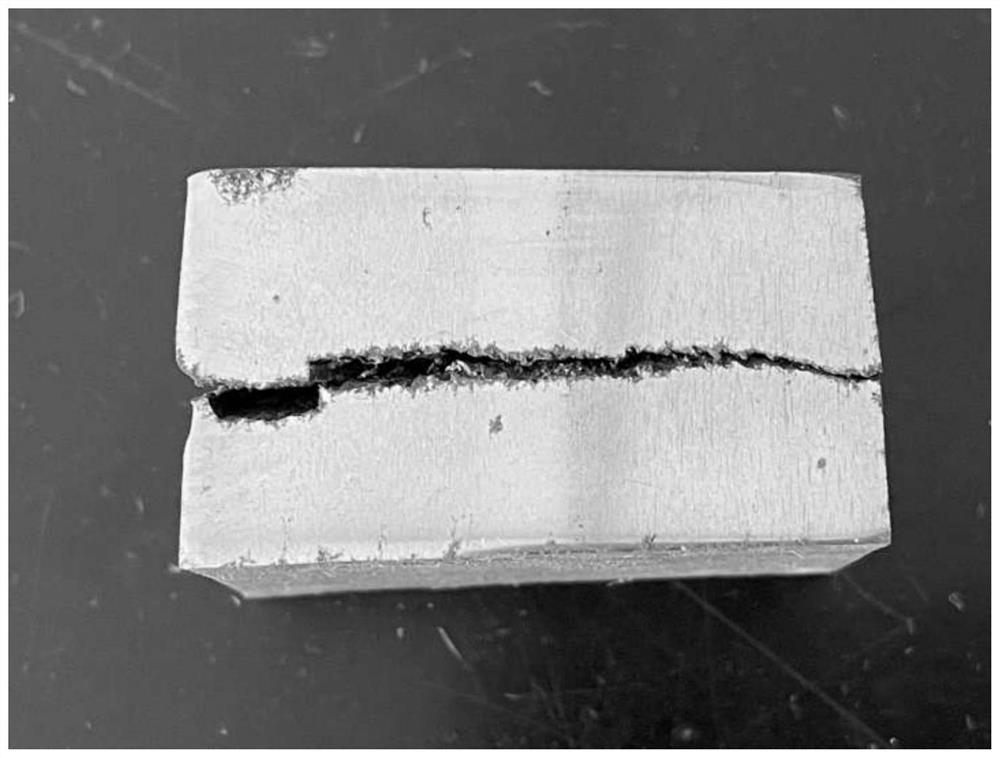

[0024] The present embodiment provides a method for treating and cleaning surface defects of corrosion and oxidation, applied to a plate Q345 specimen, the surface of which has obvious crack defects.

[0025] First place the defective specimen in 20% HCl solution and then take it out (soaking time is 5 minutes), rinse with water and then put it into 1% NaOH solution to soak (soaking time 3 minutes), rinse with water, and then use the ultrasonic cleaning machine to deeply clean the specimen, the specific operation is as follows: the beaker is loaded with anhydrous ethanol solution, and the liquid level in the beaker is higher than the surface of the fractured specimen before use, that is, the defective surface is immersed in the absolute ethanol solution Then put the beaker containing the defective specimen into the cleaning tank, inject a certain amount of distilled water into the cleaning tank, and confirm that the water level in the tank reaches one-third of the height of the tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com