Cutting equipment for plastic drainage board

A technology of plastic drainage board and splitting equipment, which is applied in metal processing and other directions, can solve problems such as human error and low efficiency, and achieve the effect of convenient operation, high work efficiency and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

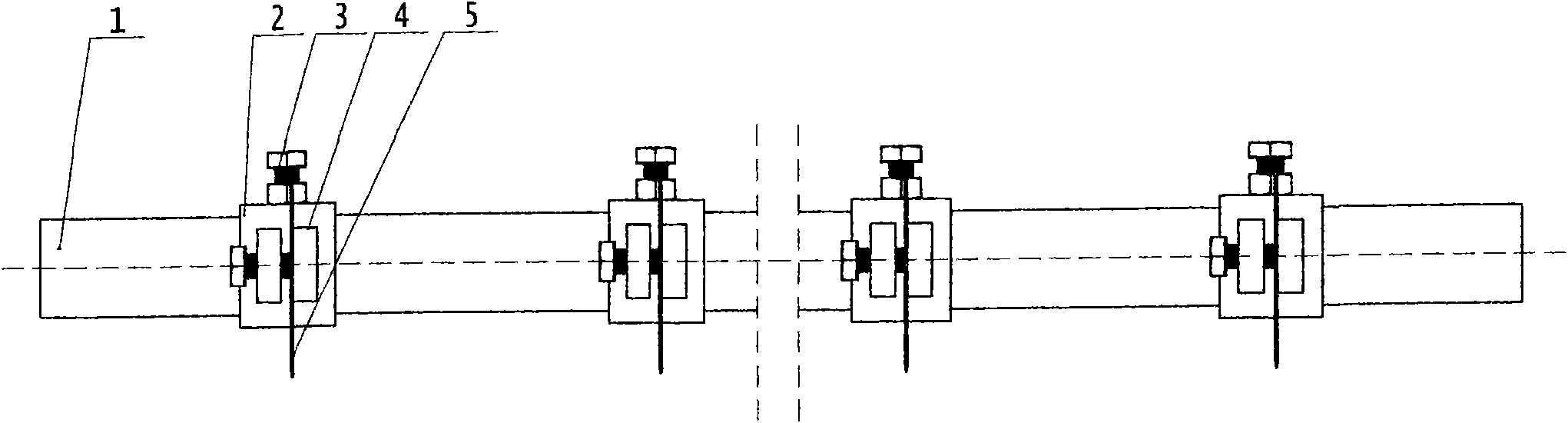

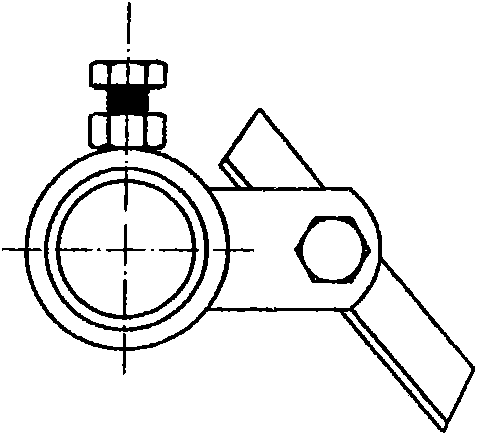

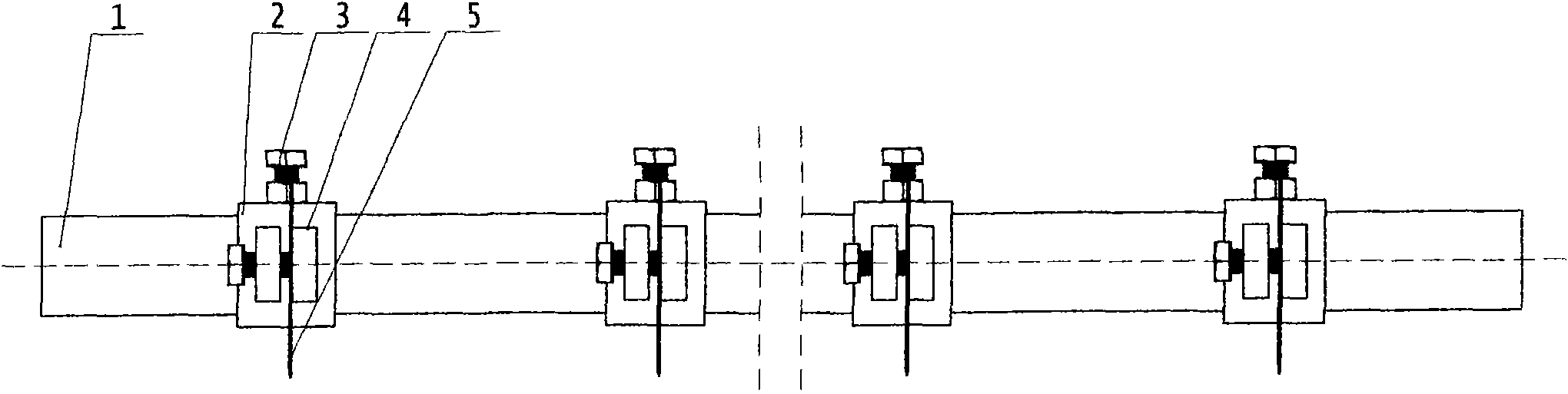

[0009] As shown in the accompanying drawings, at first a plurality of blades 5 are respectively installed on the tool holder 4 with the blade fixing bolts 2, and the tool holder 4 is installed on the tool bar main shaft 1 with the tool holder fixing bolts 3. The distance between two adjacent tool rests 4 is determined by the width of a single drainage board. The present invention can be used to make multiple drainage boards at one time, that is, the plastic cores of multiple drainage boards are placed between the upper and lower cloth coverings at one time, and the upper and lower cloths are bonded to the core board by using a high-temperature roller. Then, the present invention is used to accurately and effectively divide the wide-width drainage board according to the set specification through mechanical movement. Among the present invention, blade 5 is fixed on the tool bar main shaft 1 with knife rest 4, and the two ends of tool bar main shaft 1 are fixed in the axle hole o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com