Gas and oil separator

A technology of oil and gas separator and oil and gas separation chamber, which is applied in the direction of machines/engines, engine components, mechanical equipment, etc., which can solve the problems of increased engine oil consumption, burning, and decreased oil and gas separation efficiency, so as to achieve improvement effects and functional effects Better and improve the effect of oil and gas separation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

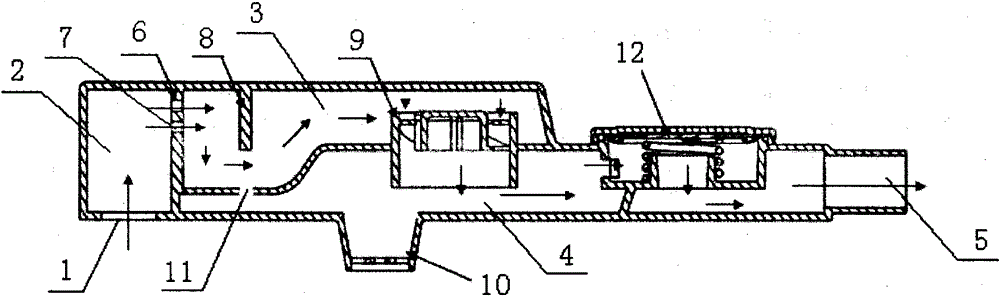

[0018] Such as figure 1 As shown, the oil-gas separator of this embodiment includes an air inlet 1, an air inlet 2 communicating with the air inlet 1, an oil-gas separation chamber 3, an air outlet 4, an air outlet 5, an air inlet 2 and an oil-air separation chamber 3 They are separated by a partition 6 with a through hole 7. A baffle 8 is arranged in the oil-gas separation chamber 3. The baffle 8 is located behind the partition 6 and faces the through hole 7 of the partition. The oil-gas separation chamber 3 passes through a The cylinder 9 with the spiral gas channel inside communicates with the air outlet 4 below, the cylinder 9 is vertically arranged behind the baffle 8, the bottom of the air outlet 4 is provided with an oil return tank 10, and the bottom plate of the oil-gas separation chamber below the baffle 8 A through hole 11 leading to the oil return tank 10 is provided, the air outlet 4 communicates with the air inlet of the PCV valve 12, the air outlet of the PCV va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com