Pneumatic tyre

A technology of pneumatic tires and tires, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problems of increasing tire noise, weakening dry road performance, etc. The effect of uniform wear and low noise values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

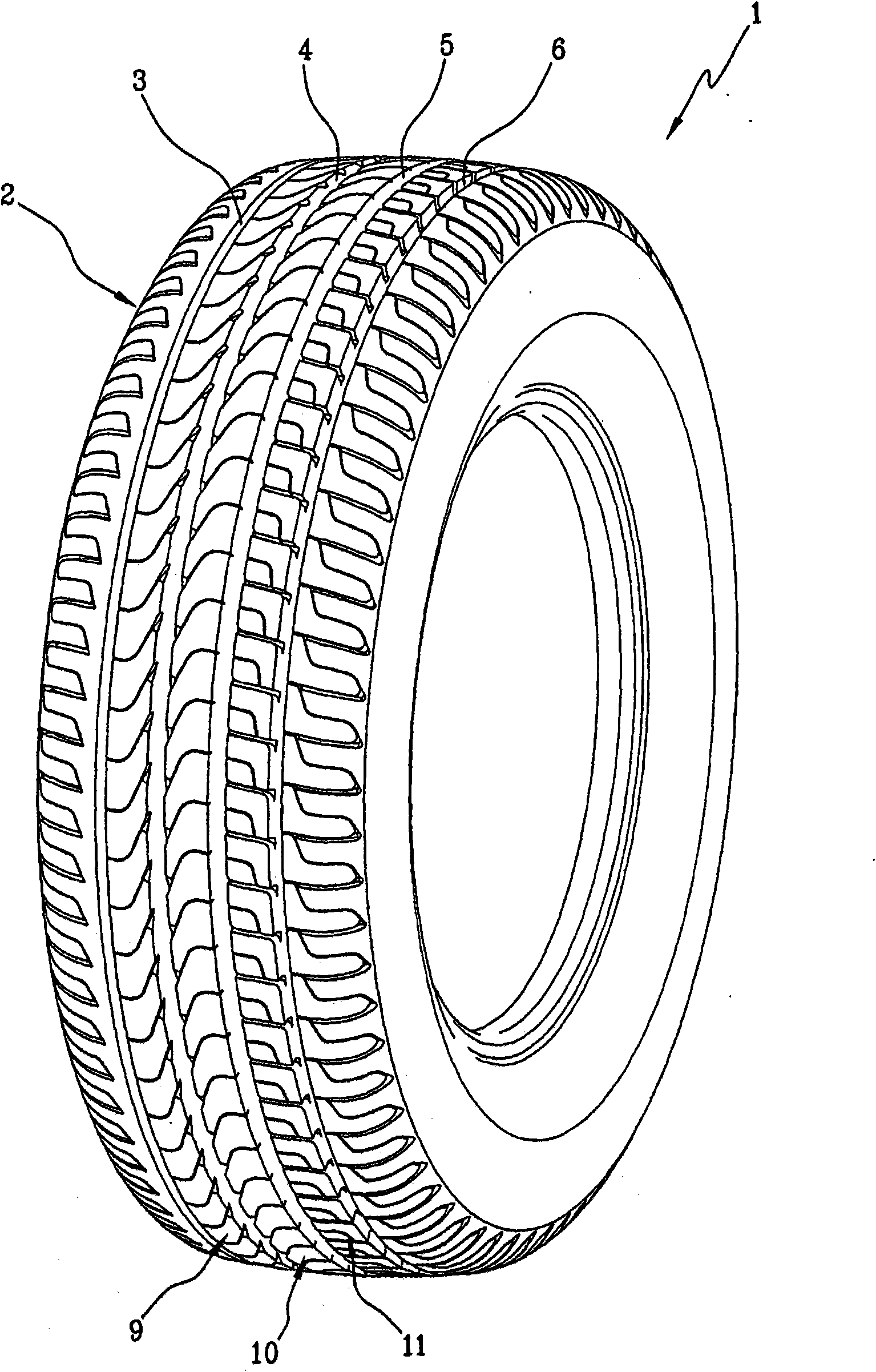

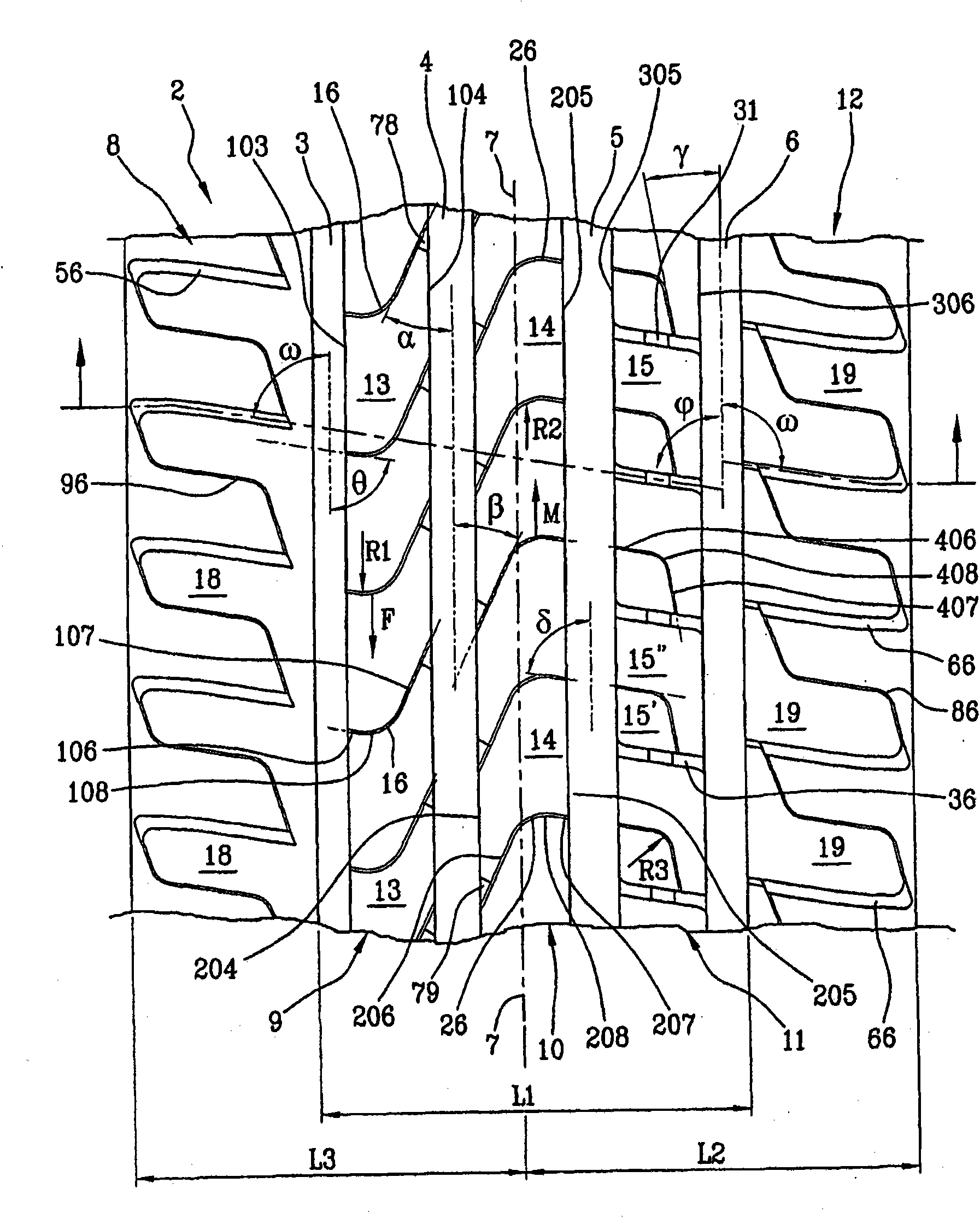

[0068] figure 1 , 2 , 2b shows a tire 1 according to the invention with a first embodiment of a tread 2 .

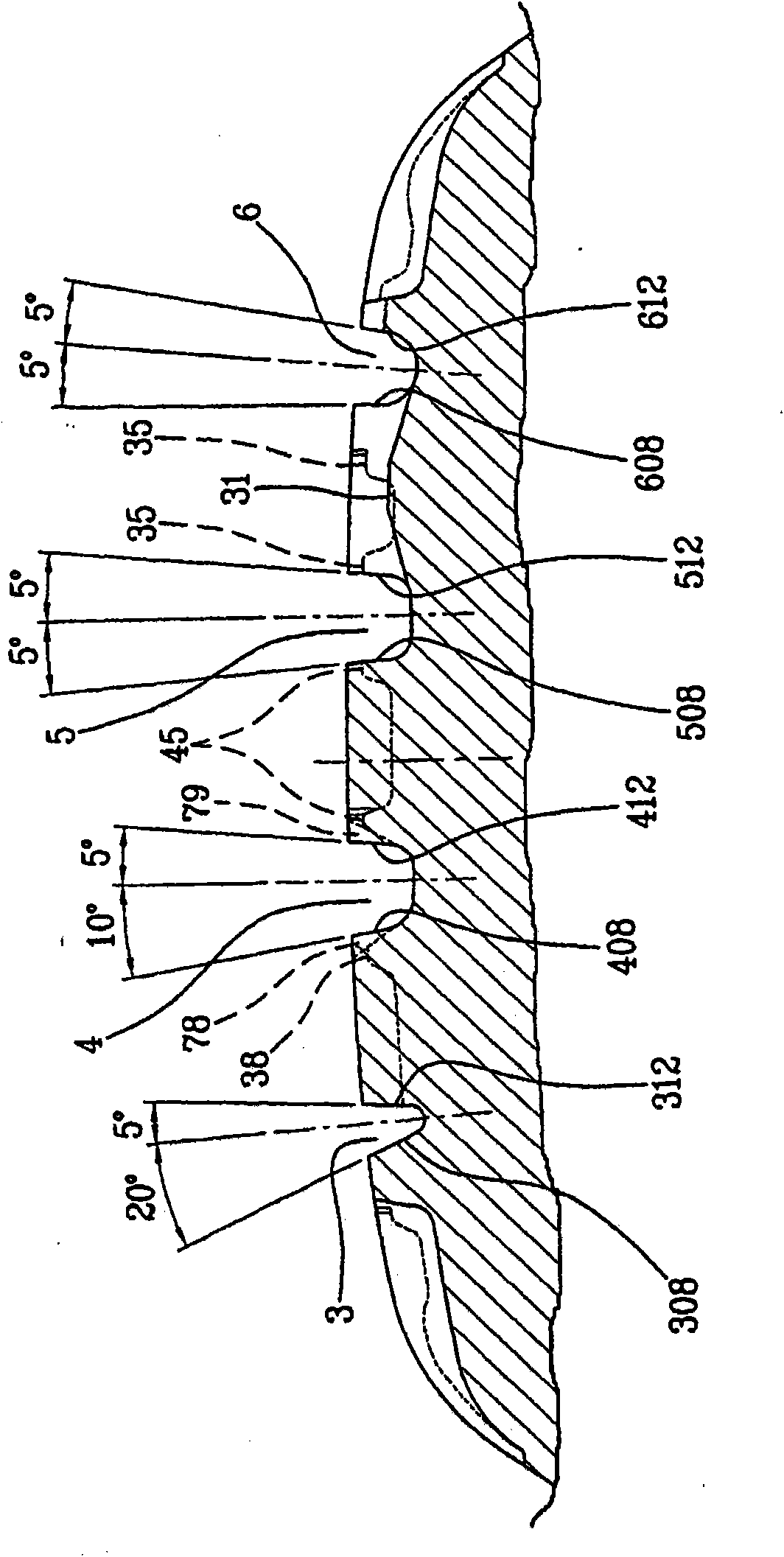

[0069] The structure of the tire 1 is of conventional type and comprises: a carcass; a tread band placed on the crown of the carcass; a pair of axially opposite sidewalls terminating in reinforcement with bead cores and corresponding bead fillers bead. The tire preferably also includes a belt structure interposed between the carcass and the tread band. The carcass is reinforced with one or more carcass plies anchored to the bead cores, while the belt structure comprises two belt strips radially overlapping each other. The straps are formed with segments of tape that are bonded to metal cords that in each strap are parallel to each other and cross (preferably symmetrically with respect to the equatorial plane) the cords of adjacent straps. way tilted). Preferably, the belt structure also comprises, at a radially outermost position, a third strap provided with cords o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com