Linear zipper tooth and zipper with linear zipper tooth

A sprocket and straight line technology, applied in the field of linear sprockets and zipper strips, can solve the problems of unsmooth use, inability to use, easy to scratch users, etc., to reduce the possibility of tooth dislocation, better anti-torsion force, and difficult to use. Effects of sprocket damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] According to the embodiment shown in the drawings, the detailed description is as follows:

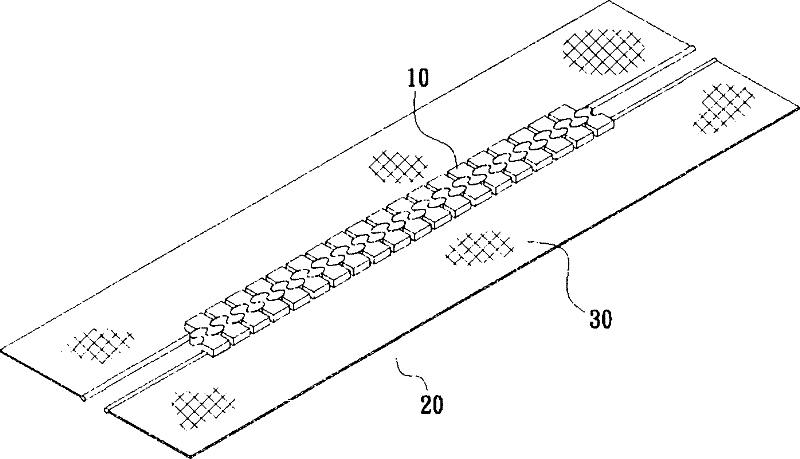

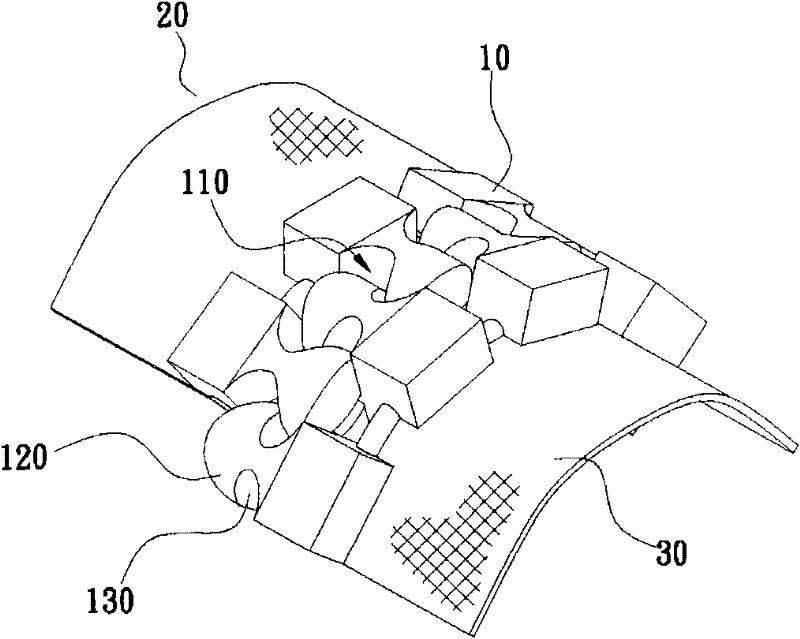

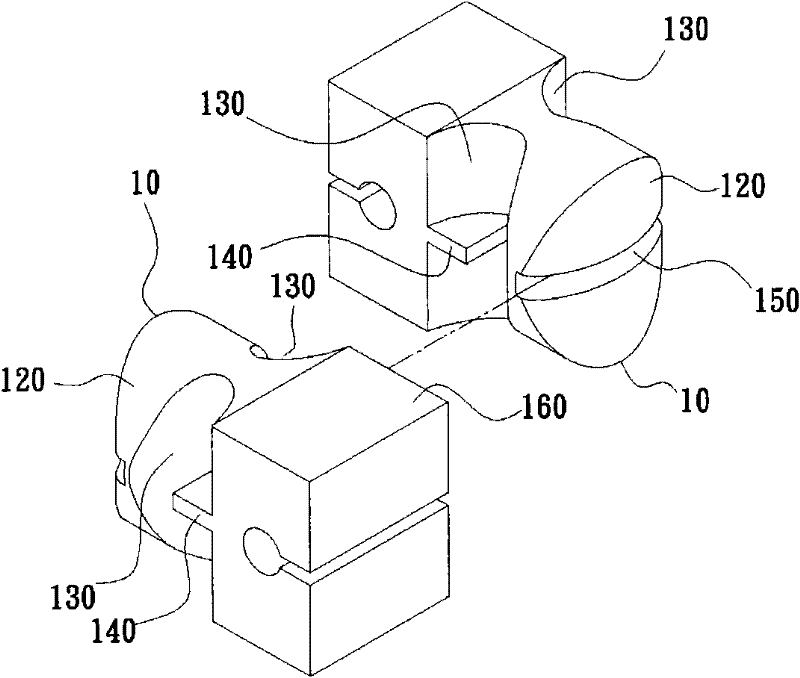

[0064] Such as Figure 5 Shown is the three-dimensional schematic view of the zipper strip of the present invention, Figure 6 Shown is the schematic diagram after the zipper strip of the present invention is bent, Figure 7 Shown is the three-dimensional structural diagram of the linear chain tooth of the present invention, Figure 8 Shown is a schematic diagram of the present invention before the two left and right linear sprockets mesh.

[0065] The figure shows a linear sprocket 1, which can be a metal sprocket or a plastic steel sprocket, and includes a clamping portion 7 with a slit 2 at one end to firmly clamp the zipper tape. The front side of 7 is the second wall surface 12 of the linear sprocket 1; a barb-shaped engaging part 3 extending outward from the other end side of the above-mentioned clamping part 7, and an engaging groove corresponding to the engaging part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com