Automated dynamic cleaning device and method of tellurium-cadmium-mercury wafer solvent solution

A technology for cleaning devices and wafers, used in cleaning methods using liquids, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of lack of stability and repeatability, limited shaking times, and chipping of wafers. Effective consistency and repeatability, guaranteed reliability and repeatable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

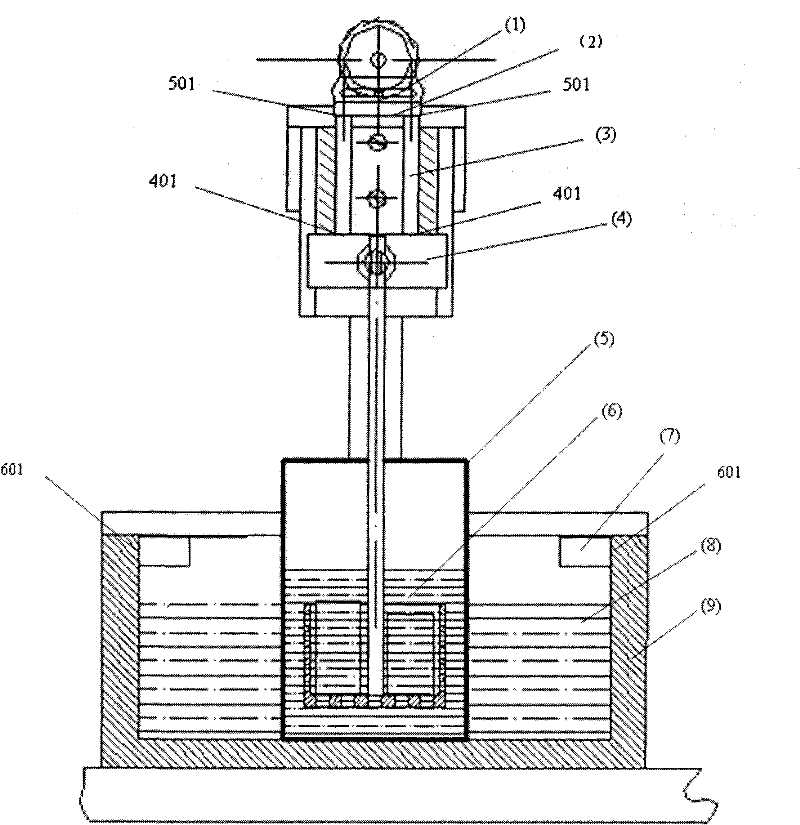

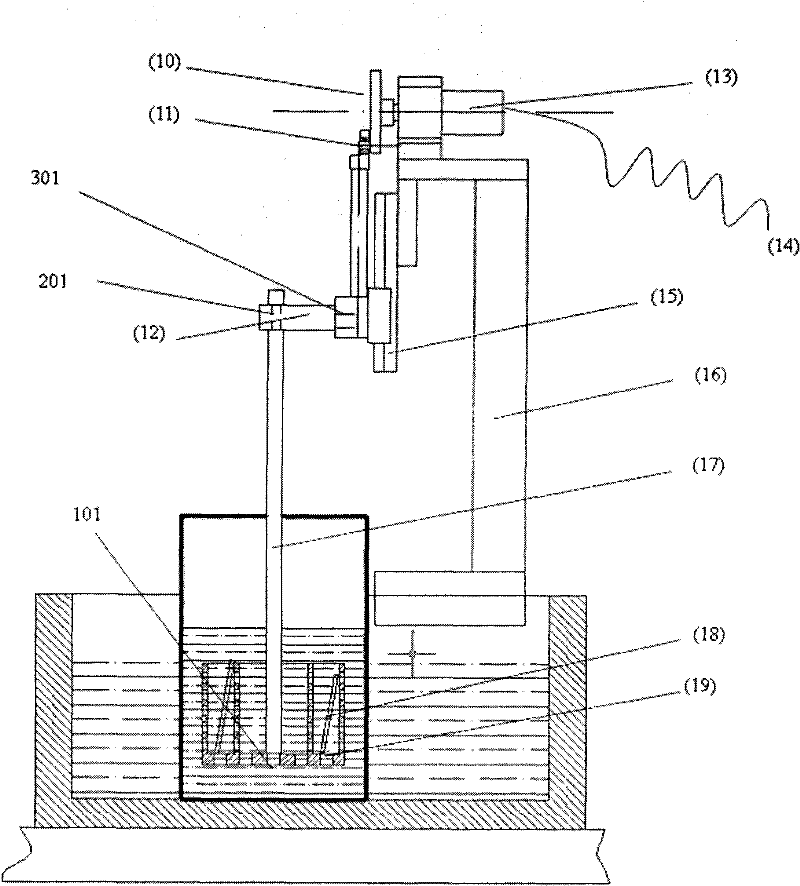

[0025] The organic or inorganic cleaning solution 6 is poured into a quartz beaker 5 , and the quartz beaker is placed in a constant temperature water tank 9 and a water bath 8 . The tellurium mercury barrier wafer 18 is erected in a polytetrafluoroethylene porous flower basket 19 and immersed in a quartz beaker filled with solvent, and the DC speed control power supply 14 is turned on to start the DC motor 13 to drive the dial 10 and the lever 11 to make a circle in the chute 1. The slider moves up and down in the guide rail 15, and the PTFE porous flower basket is connected up and down through the flower basket handle 17, the lever arm 12, the slider 4, the chute 1 and other components to achieve the purpose of dynamic cleaning.

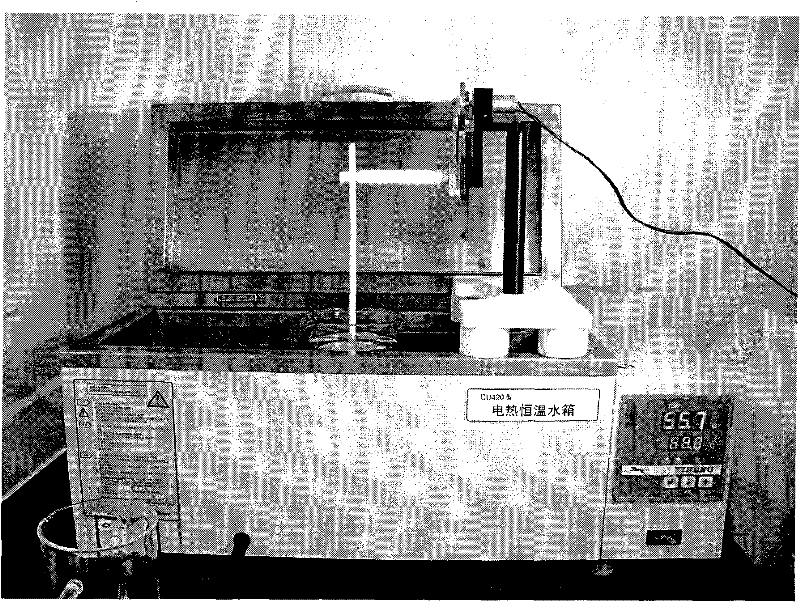

[0026] The automatic dynamic device for cleaning the tellurium mercury barrier wafer solvent solution of the present invention has been successfully used in the development process of the tellurium mercury barrier infrared detector. image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com