Connecting piece used for assembling guardrail cross beams and guardrail upright posts

A technology of guardrail columns and connectors, which is applied to bridge parts, bridges, fences, etc., can solve the problems affecting the service life and safety of guardrails, the connection between columns and beams is bulky, and affects the overall beauty of guardrails. Stable and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

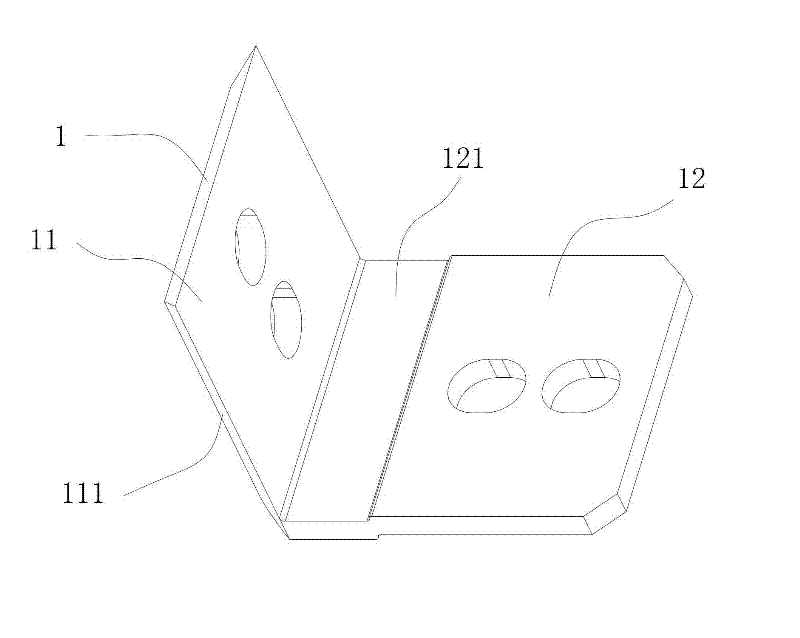

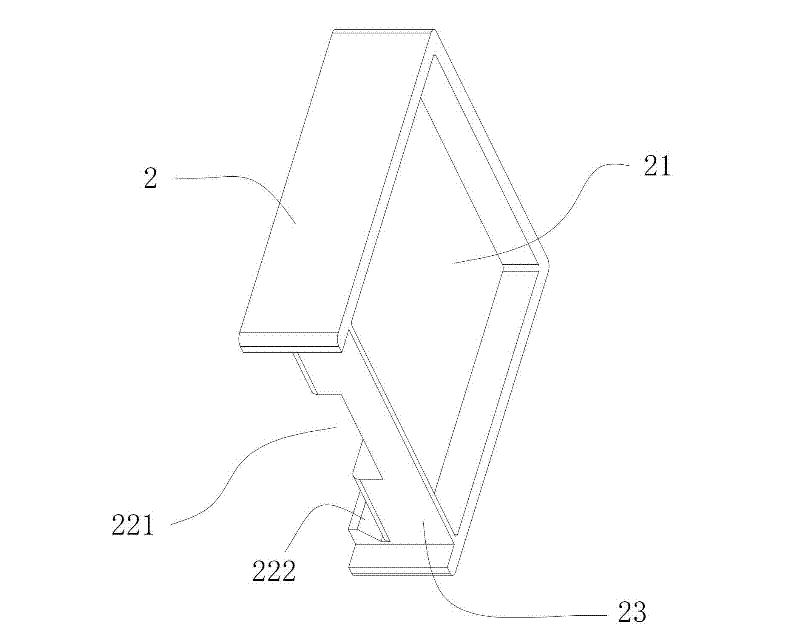

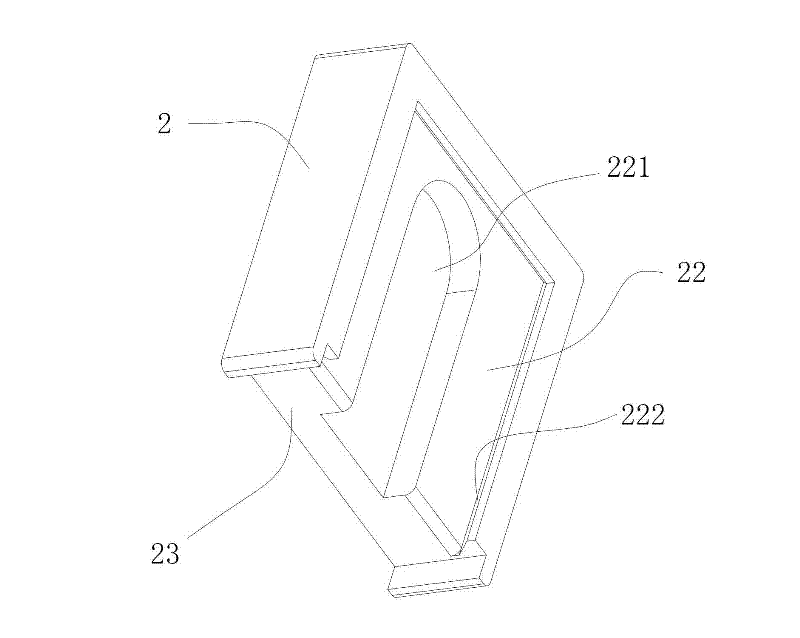

[0021] Figure 1 to Figure 5 Shown is an embodiment of a connector for assembling a guardrail beam and a guardrail column of the present invention, the connector includes an L-shaped bracket 1, and the L-shaped bracket 1 is composed of a first side plate 11 for connecting a guardrail column 3 and a It is composed of the second side plate 12 connected to the guardrail beam 4, the second side plate 12 is equipped with a sealing sleeve 2, and one side of the sealing sleeve 2 is provided with a first interface 21 for socketing with the end of the guardrail beam 4. The present invention is simple in structure, easy to assemble and disassemble, and is equipped with the first interface 21 of sealing sleeve 2 to carry out effective waterproof protection to the cutout of guardrail beam 4 end, avoids its generation of corrosion.

[0022] In this embodiment, the other side of the sealing sleeve 2 is provided with a second interface 22 socketed with the first side plate 11, and the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com