Crystal oscillator oscillation test fixture

A technology of vibration testing and crystal vibration, which is applied in the field of electronic communication, can solve problems such as high cost, low efficiency of batch vibration experiments, and difficulties in crystal vibration experiments, and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

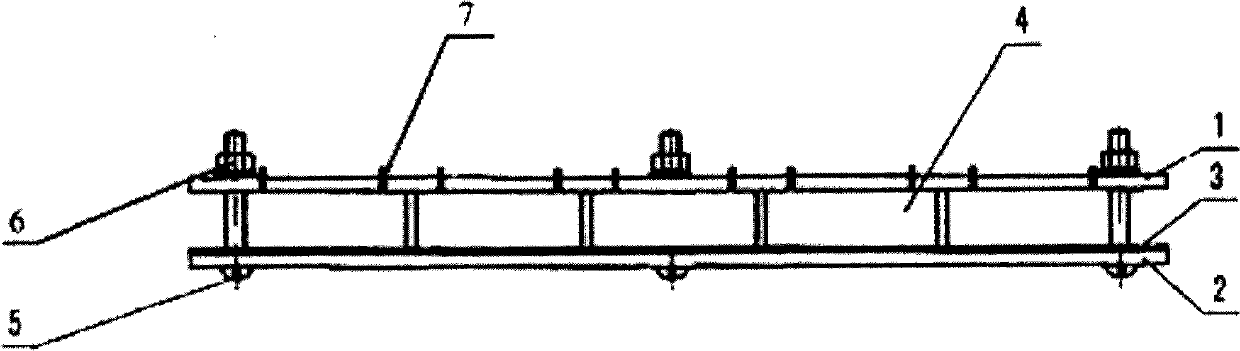

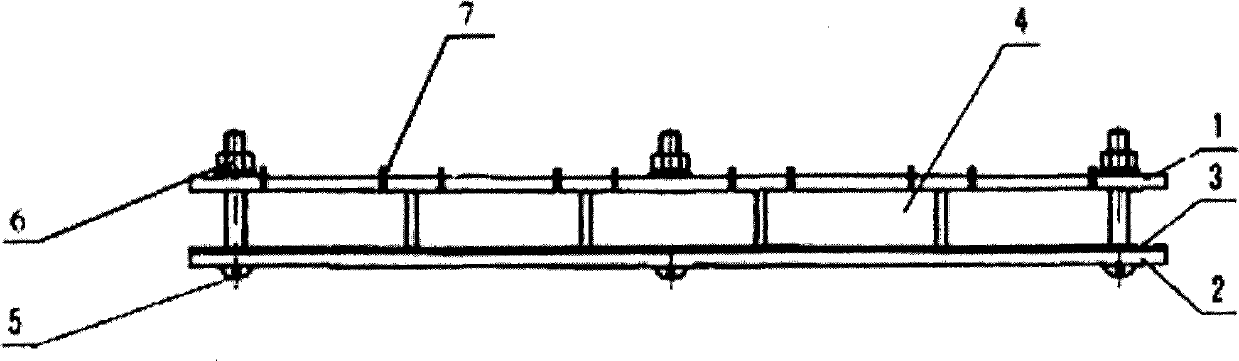

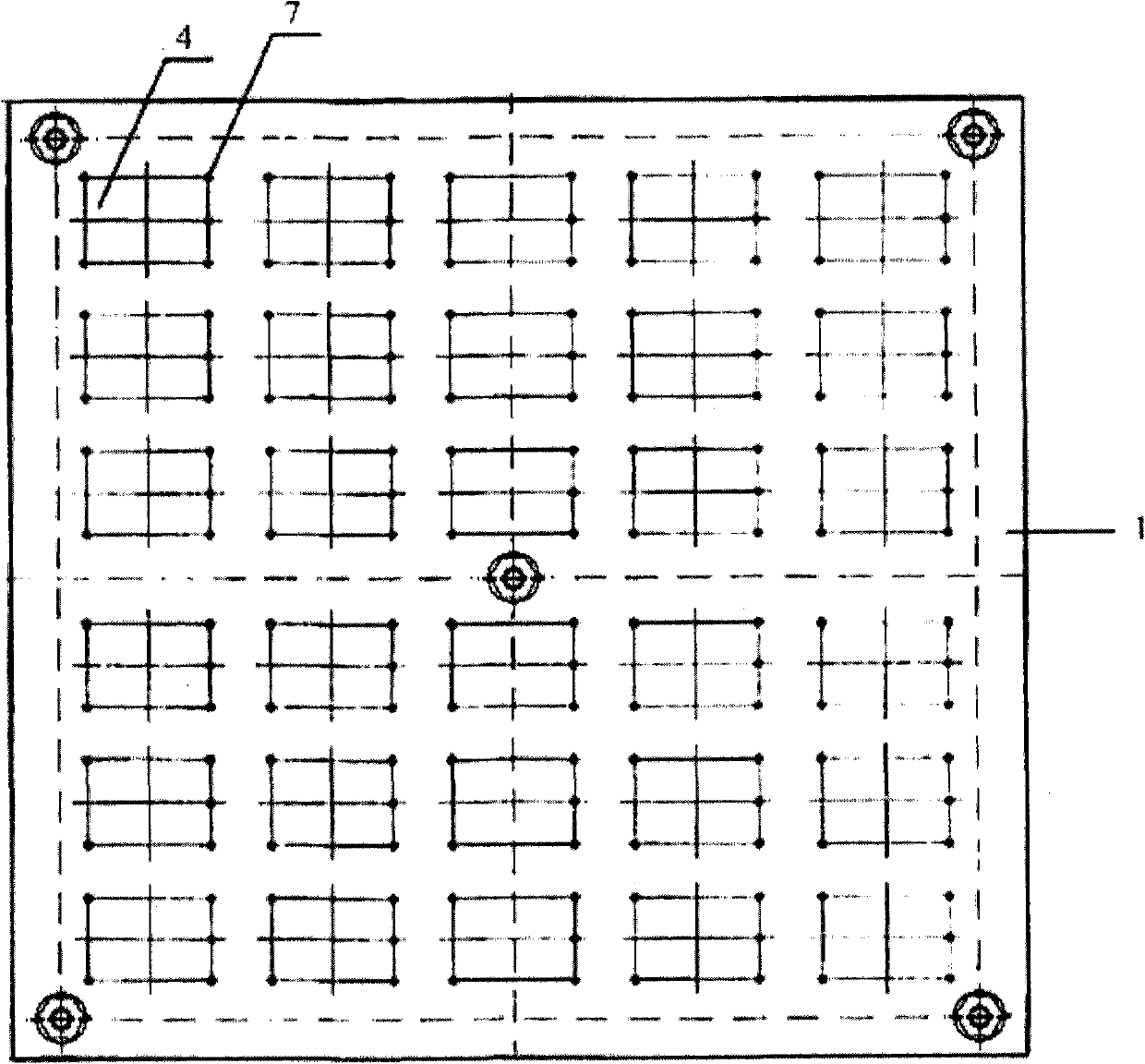

[0024] The detailed structure, application principle, function and effect of the present invention refer to the appendix Figure 1-4 , which will be described by the following embodiments.

[0025] see Figure 1-4 As shown, the crystal vibration test fixture of the present invention is composed of a positioning plate 1, a pressure plate 2, a backing plate 3 and a connecting piece, and 30 crystal oscillators 4 to be tested are arranged in the upper part of the Between the positioning plate 1 and the backing plate 3 arranged at the lower part, the number of pins of each crystal oscillator 4 to be tested is 4, which respectively pass through the corresponding openings on the positioning plate 1 . There is a pressure plate 2 below the backing plate 3; the aforementioned positioning plate 1, pressing plate 2, and backing plate 3 are fixedly connected by five groups of connecting pieces, and the connecting pieces are respectively arranged at the four corners and the center position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com