Handle clip with self-contained elastic sheet

A shrapnel and handle technology, applied in the field of handle clips, can solve the problems of easily broken spring pieces and short service life, and achieve the effects of not easy to break, long service life, and small reciprocating motion range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

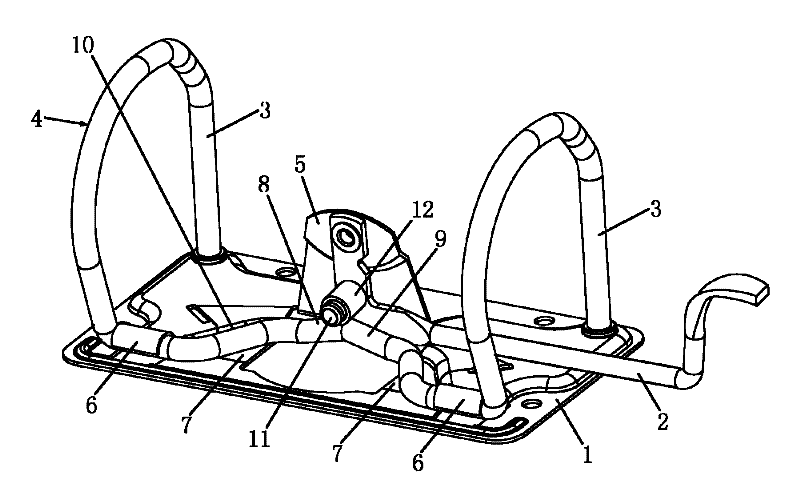

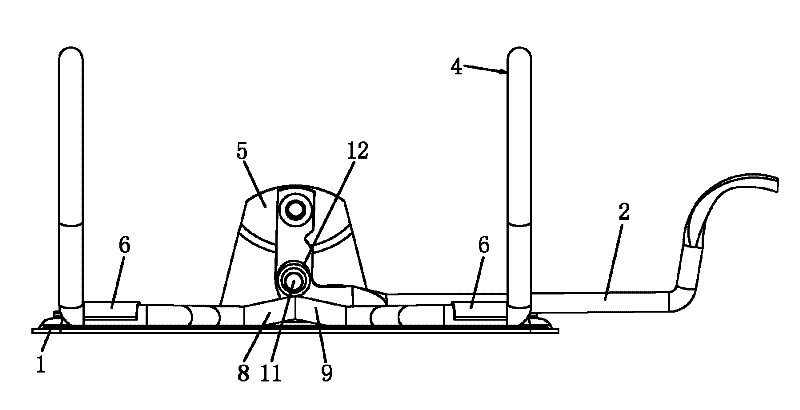

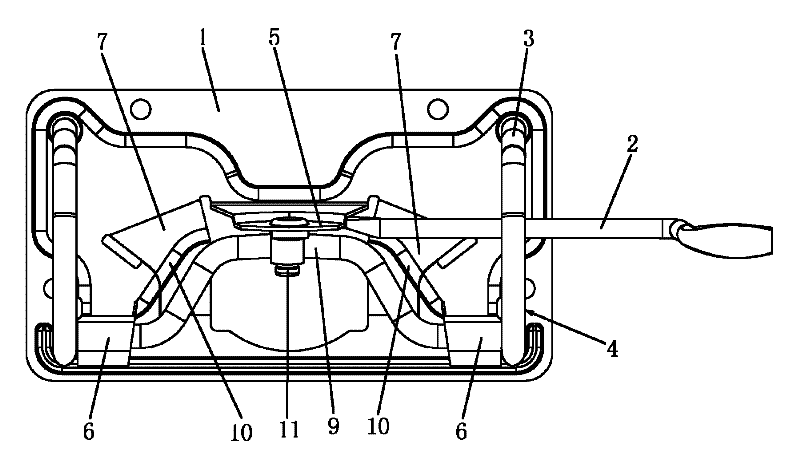

[0026] The embodiment of a handle clip with self-shrapnel of the present invention is as follows: Figures 1 to 8 As shown, it includes a bottom plate 1, a handle 2, a curved needle 3 and a hook frame 4, the middle of the bottom plate 1 is provided with a middle ear 5, the inner end of the handle 2 is hinged to the middle ear 5, the curved needle 3 is fixed on the bottom plate 1, and the hook frame 4 is two The sides are respectively provided with connecting parts, the hook frame 4 is pivotally connected to the bottom plate 1 through the connecting parts, and the hook frame 4 overlaps with the curved needle 3 and forms a closed loop body together with the curved needle 3 during clamping.

[0027] Both sides of the hook frame 4 are provided with a rotating shaft and an arm body, and the arm bodies are used to overlap the corresponding curved needles 3 arranged on both sides of the bottom plate 1, wherein an arm body of the hook frame 4 and a corresponding curve on the bottom pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com