Backrest of vehicle seat

A technology for car seats and backrests, applied in seat frames and other directions, can solve the problems of large thickness, affecting the line of sight of people in the rear row, and crowded space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

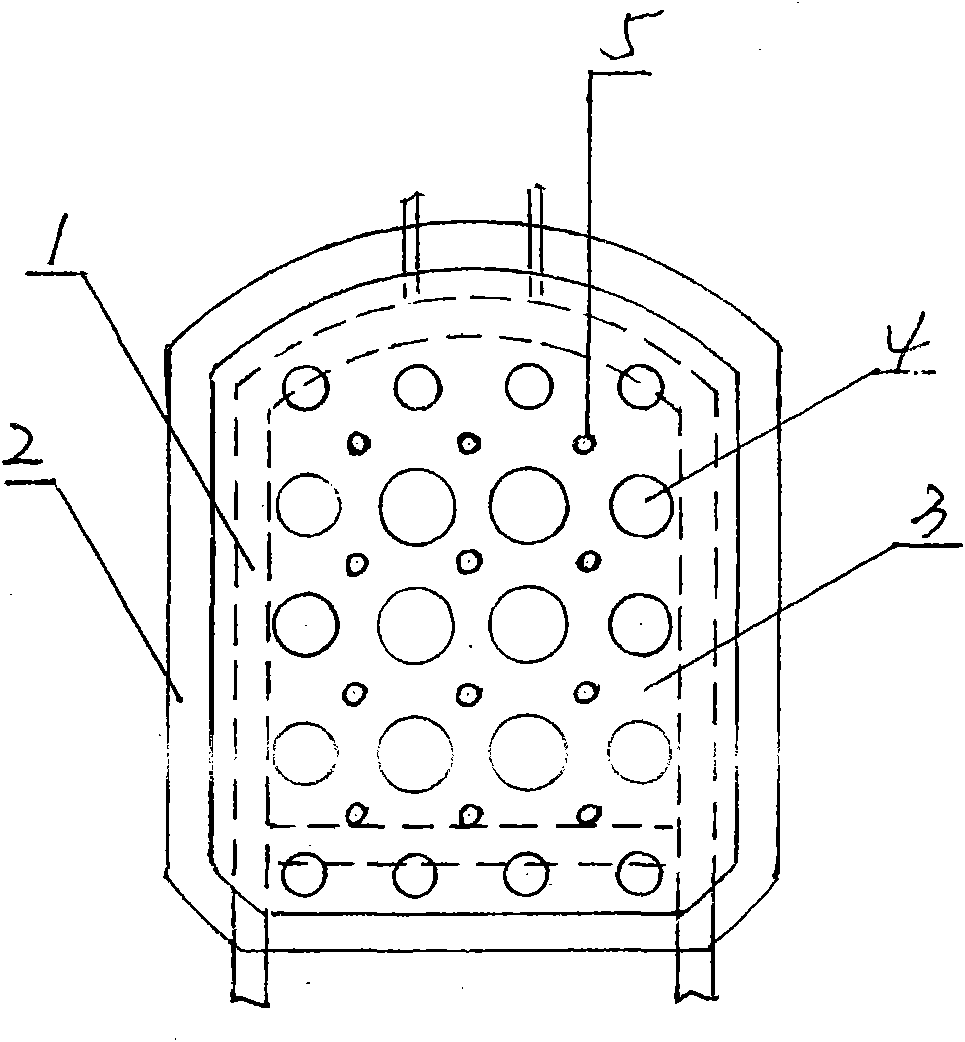

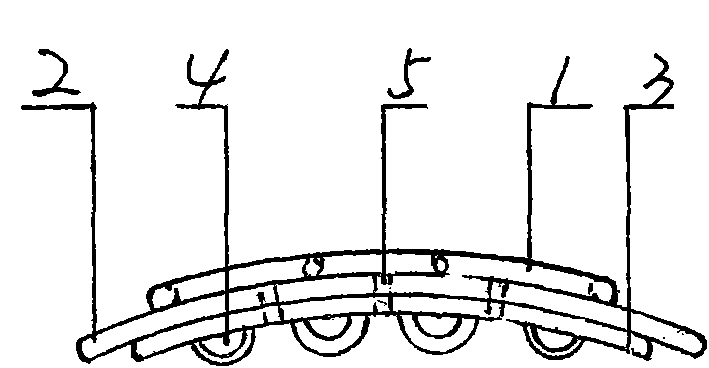

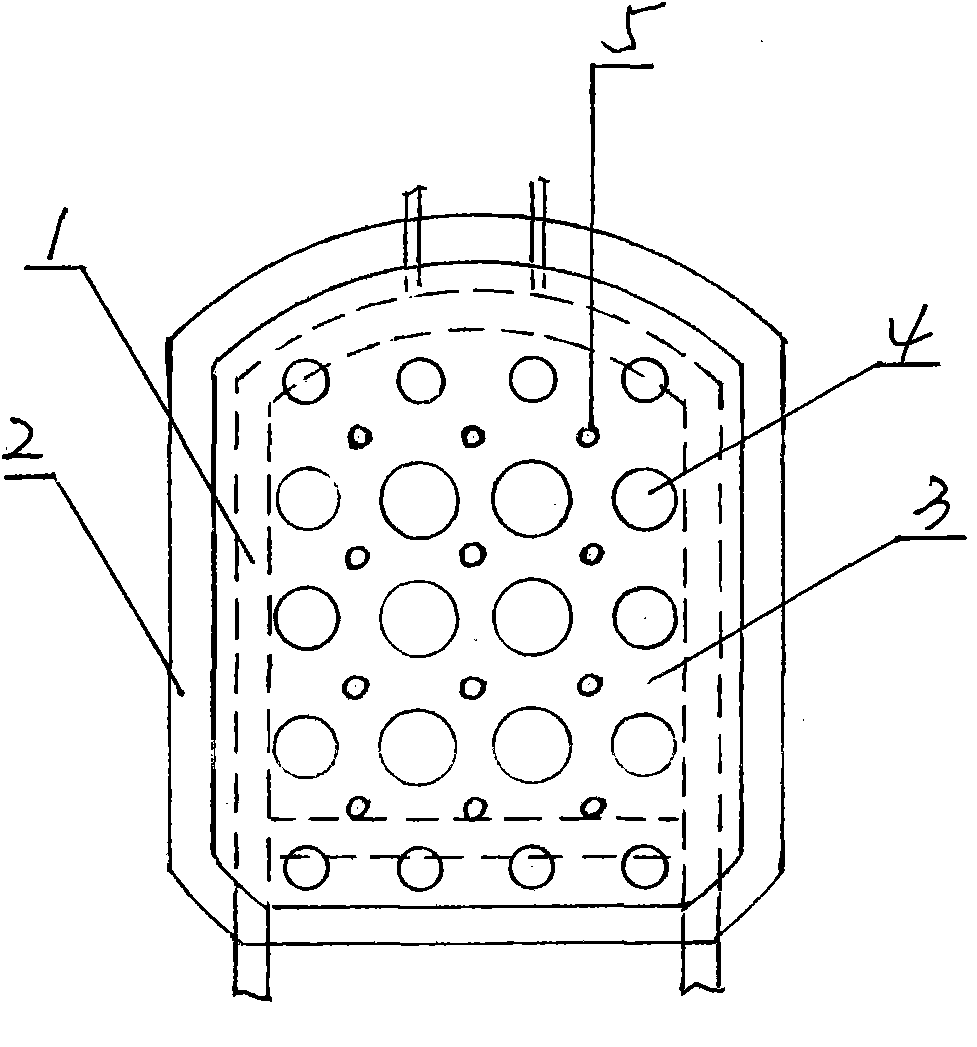

[0006] Such as figure 1 , 2 Shown, this backrest can be refitted with existing seat backrest, and structure is made up of backrest frame 1, backboard 2, bubble board 3. The existing backrest frame 1 and the angle adjustment structure and the headrest frame are not changed, the existing backrest board and back cover are removed and used, and the backrest board 2 is connected to the existing backrest frame 1, and the backrest board 2 is fixed on the backrest frame 1 On, the backboard 2 adopts the transparent plastic material die-casting that has toughness to form, and its periphery is made arc-shaped, and the shape of the backboard 2 is identical with the size of the existing backboard, and its thickness is between 1-2 centimetres. 2 is distributed with some exhaust air holes 5, as the usefulness of improving ventilation. Bubble board 3 is pasted and fixed on the backboard 2 with adhesive or transparent glue, and the periphery of bubble board 3 is slightly smaller than backboa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com