All-fiber current transformer and working method thereof

A current transformer and all-fiber technology, applied in the direction of voltage/current isolation, etc., can solve serious problems, temperature effects, poor temperature stability of the system, etc., and achieve the effects of improving sensitivity, eliminating birefringence, and improving phase sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention provides an all-optical fiber current transformer, and the specific implementation manner of the present invention will be described in detail below with reference to the accompanying drawings.

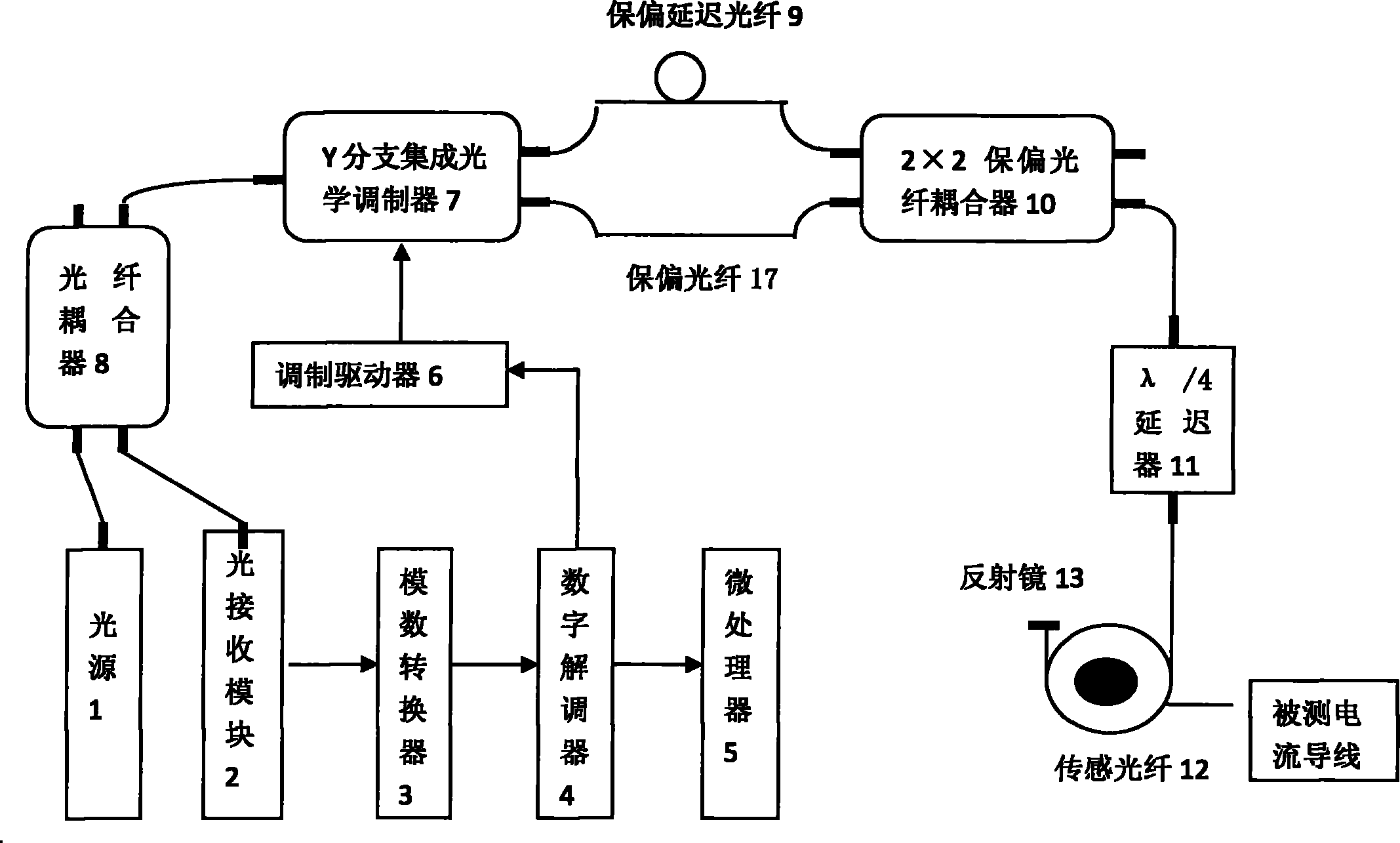

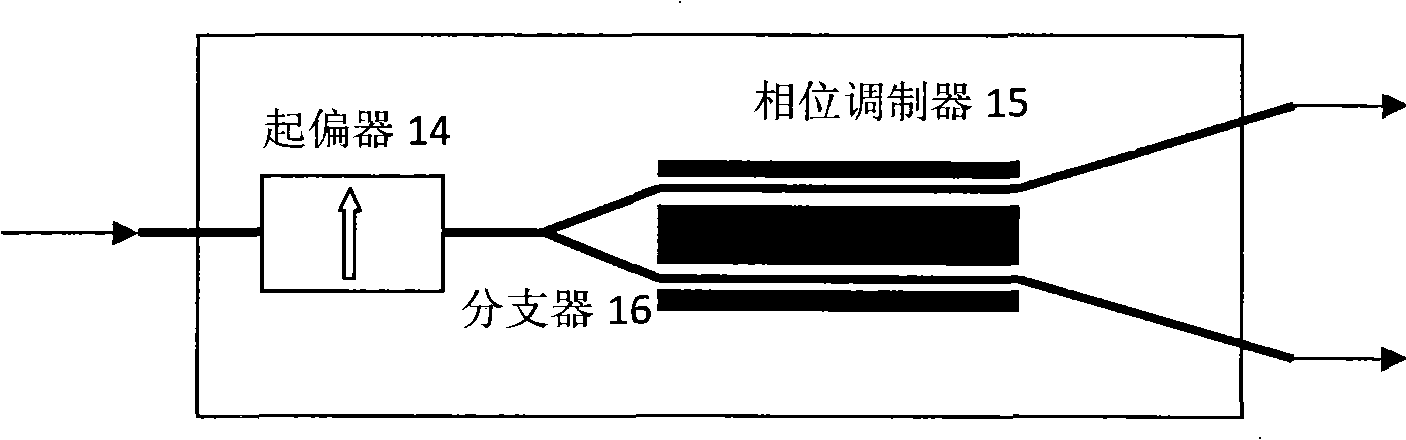

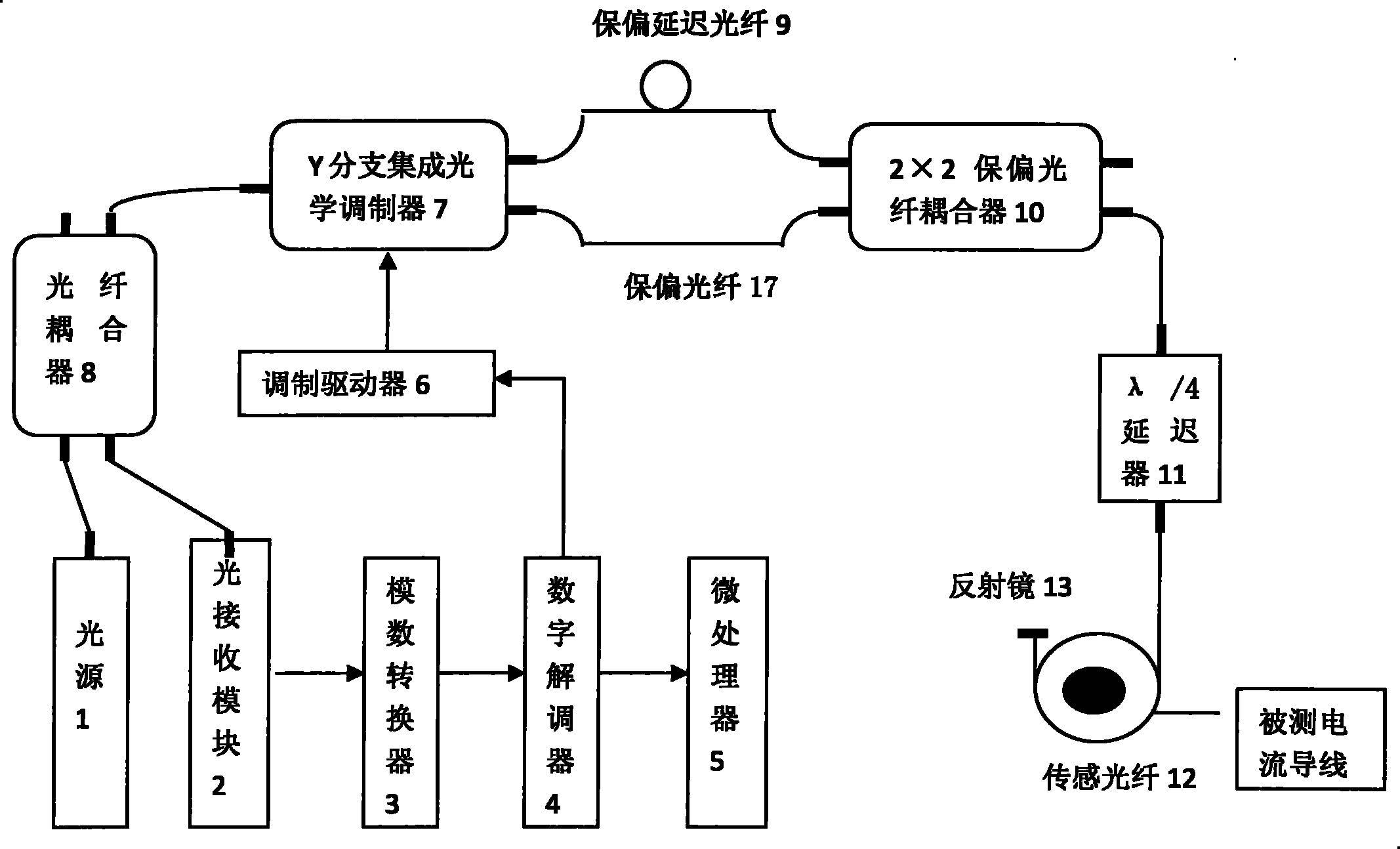

[0037]An all-fiber current transformer, comprising a light source 1, an optical receiving module 2, an analog-to-digital converter 3, a digital demodulator 4, a microprocessor 5, a modulation driver 6, a Y branch integrated optical phase modulator 7, and a fiber optic coupler 8. Composed of polarization maintaining delay fiber 9, polarization maintaining fiber 17, polarization maintaining fiber coupler 10, λ / 4 delayer 11, sensing fiber 12 and reflector 13. The connection method is: the optical output end of the light source 1 is input to the first input end of the fiber coupler 8, the light receiving module 2 is connected to the second input end of the fiber coupler 8, the light receiving module 2, the digital converter 3, the digital solution The modulato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com