Monitoring and detecting device on stirring tank

A detection device and stirring tank technology, applied in the direction of instruments, computer control, simulators, etc., can solve the problems of inability to spot inspection of stirring tanks, and achieve the effect of eliminating potential safety hazards and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the present invention will be further described.

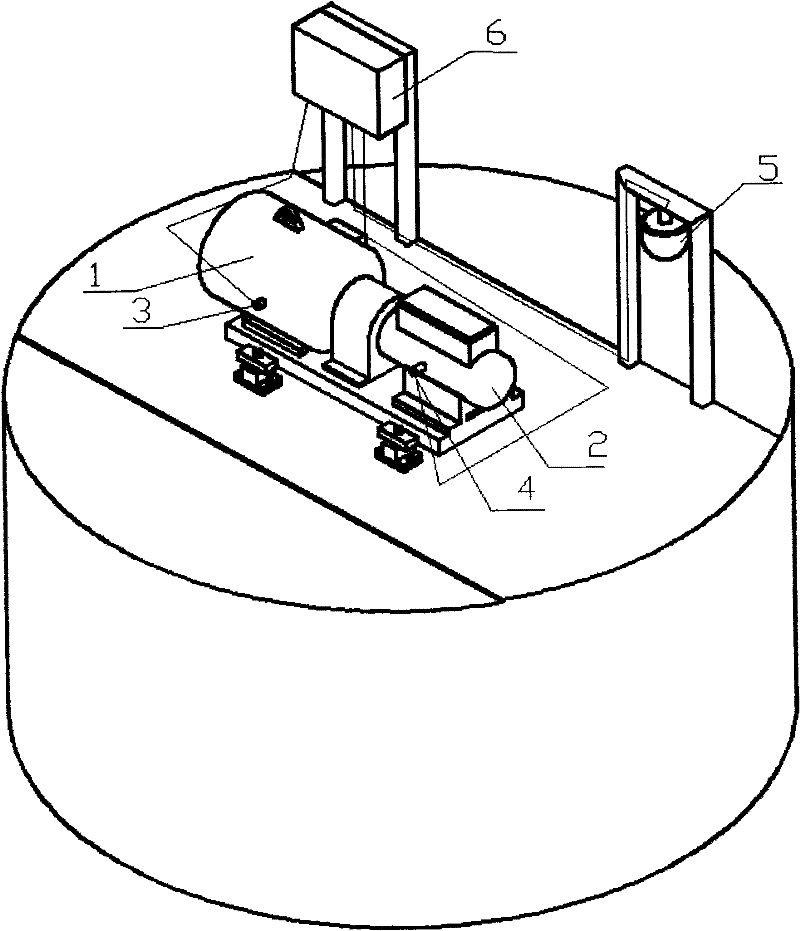

[0023] Such as figure 1 As shown, the monitoring and detection device of the present invention includes a motor temperature detector 3 , a reducer temperature detector 4 , a video acquisition device 5 and a junction box 6 .

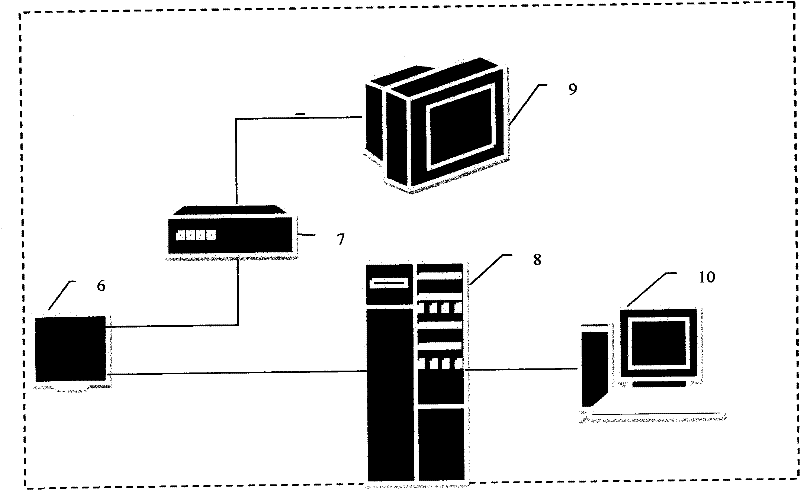

[0024] Such as figure 1 As shown, the video acquisition device 5 is installed on the top of the stirring tank through a bracket about 1.5 meters high. In order to collect the information of each corner in the stirring tank, the video acquisition device adopts a video acquisition device that can rotate and collect in all directions, and the video signal passes through After the junction box 6 is sent to the central control room switch 7, it is directly fed back on the pumping station video monitor 9 (such as figure 2 shown).

[0025] The two temperature detectors 3 and 4 adopt PT100 thermal resistance temperature sensors, which are respectively ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com